Norac UC5 Topcon X30 User manual

Other manuals for UC5 Topcon X30

55

Table of contents

Other Norac Paint Sprayer manuals

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4 Total Control User manual

Norac

Norac UC4+ User manual

Norac

Norac UC 4.5 Hagie STS10 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

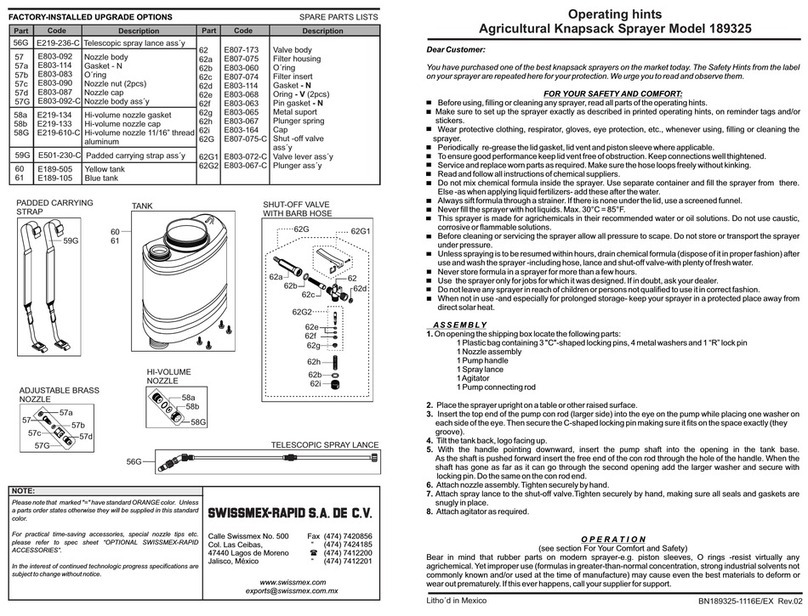

Popular Paint Sprayer manuals by other brands

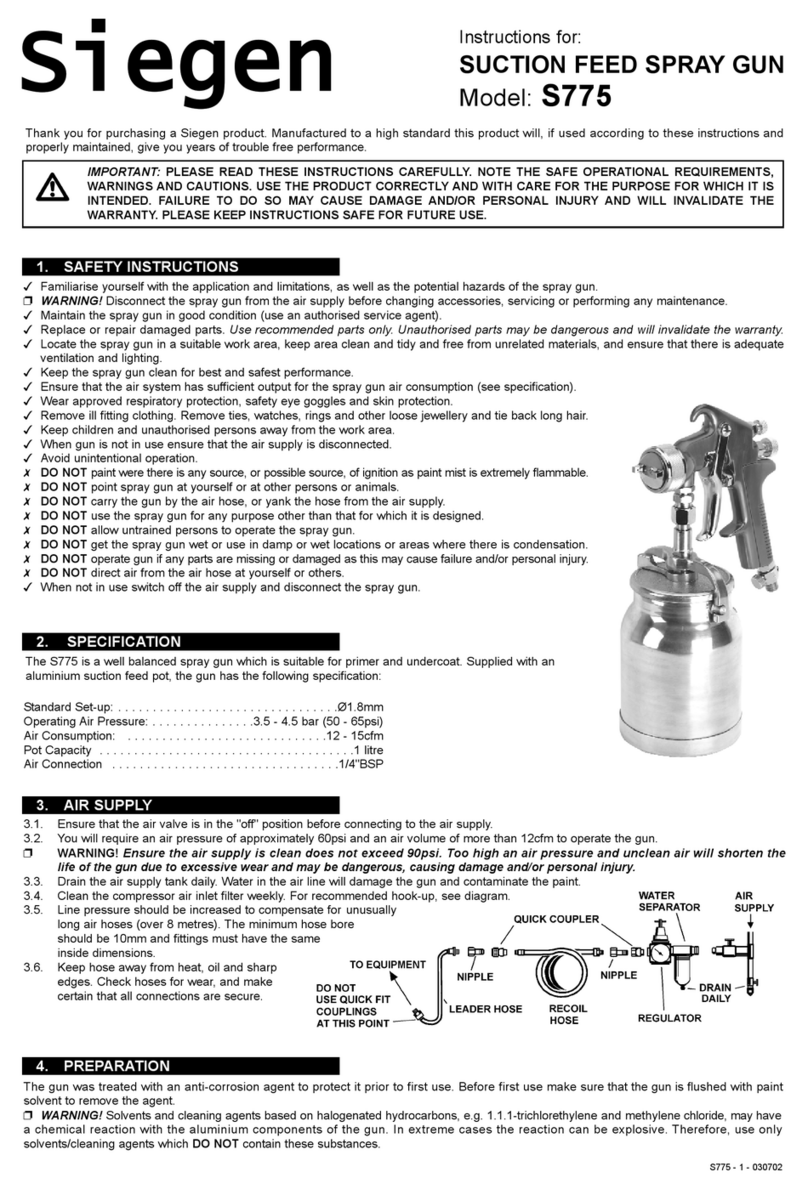

Graco

Graco Magnum X5 owner's manual

Ecco

Ecco Ecco 65S Spare parts list

Casotti

Casotti AQUILOTTO 1 SIDE FC8 Instruction for the installation and the adjustment

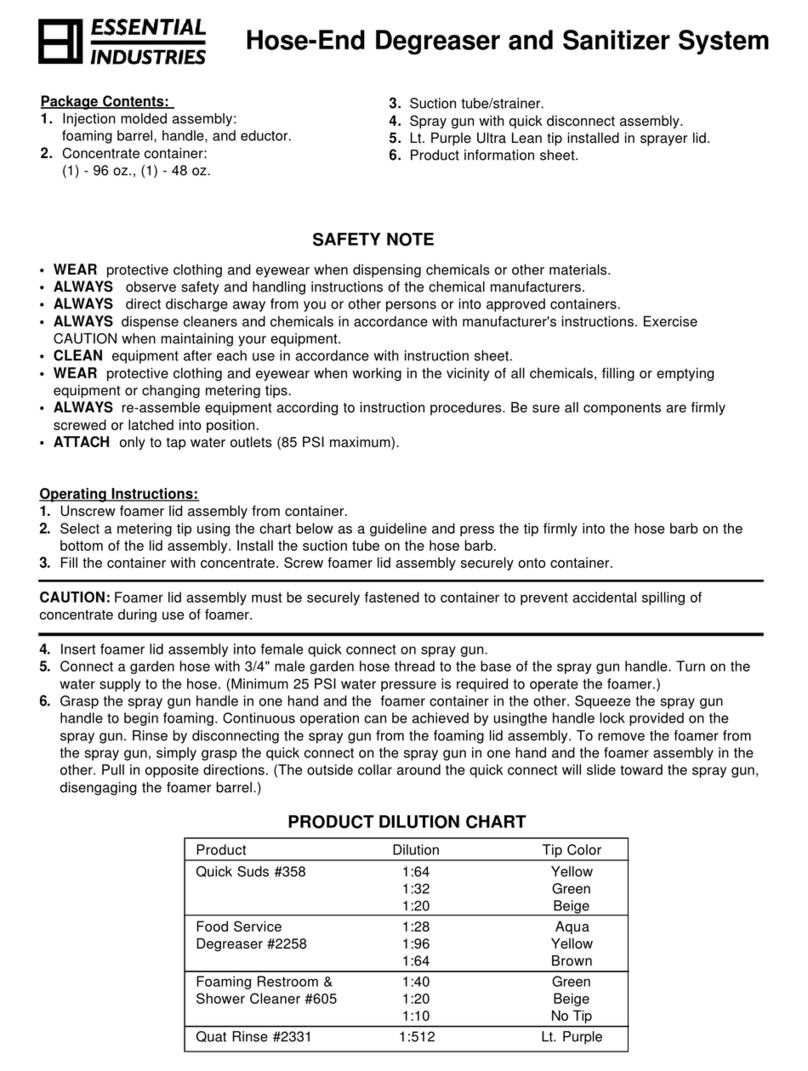

Essential Industries

Essential Industries Hose-End instructions

WALTHER PILOT

WALTHER PILOT WA 55 Operating instruction

Uni-ram

Uni-ram UG1000 Series operating manual