Norac UC4.5 User manual

Rogator ’64 and ’74 Series

and Willmar Eagle 8650 (JIC) &

’84, ’94 & 1386 Series (Flat Faced O-Ring)

Installation Manual

RG2 & RG6

Printed in Canada

Copyright 2012 by NORAC Systems International Inc.

Reorder P/N: UC4.5-BC-RG2-INST Rev I (Rogator ’64 and ’74 Series and Willmar Eagle 8650

(JIC) &’84, ’94 & 1386 Series (Flat Faced O-Ring))

NOTICE: NORAC Systems International Inc. reserves the right to improve products and their specifications without notice and

without the requirement to update products sold previously. Every effort has been made to ensure the accuracy of the information

contained in this manual. The technical information in this manual was reviewed at the time of approval for publication.

Contents

1Introduction................................................................................................................ 1

2General UC4.5 System Layout................................................................................. 2

3Kit Parts ...................................................................................................................... 3

4Pre-Install Checklist................................................................................................. 11

5Ultrasonic Sensor Installation ................................................................................ 12

6Roll Sensor Installation............................................................................................ 16

7Electrical Installation ............................................................................................... 19

8Hydraulic Installation .............................................................................................. 24

9Software Setup......................................................................................................... 28

10Cable Drawings ........................................................................................................ 29

1

1Introduction

Congratulations on your purchase of the NORAC UC4.5 Spray Height Controller. This system

is manufactured with top quality components and is engineered using the latest technology to

provide operating reliability unmatched for years to come.

When properly used the system can provide protection from sprayer boom damage, improve

sprayer efficiency, and ensure chemicals are applied correctly.

Please take the time to read this manual completely before attempting to install the system. A

thorough understanding of this manual will ensure that you receive the maximum benefit from

the system.

Your input can help make us better! If you find issues or have suggestions regarding the parts

list or the installation procedure, please don’t hesitate to contact us.

Every effort has been made to ensure the accuracy of the information contained in

this manual. All parts supplied are selected to specially fit the sprayer to facilitate

a complete installation. However, NORAC cannot guarantee all parts fit as

intended due to the variations of the sprayer by the manufacturer.

Please read this manual in its entirety before attempting installation.

2

2General UC4.5 System Layout

Figure 1 illustrates the general layout of the UC4.5 system components:

Figure 1: General UC4.5 System Layout

3

3Kit Parts

3.1 Kit Overview

Figure 2: RG2/RG6 System Parts

4

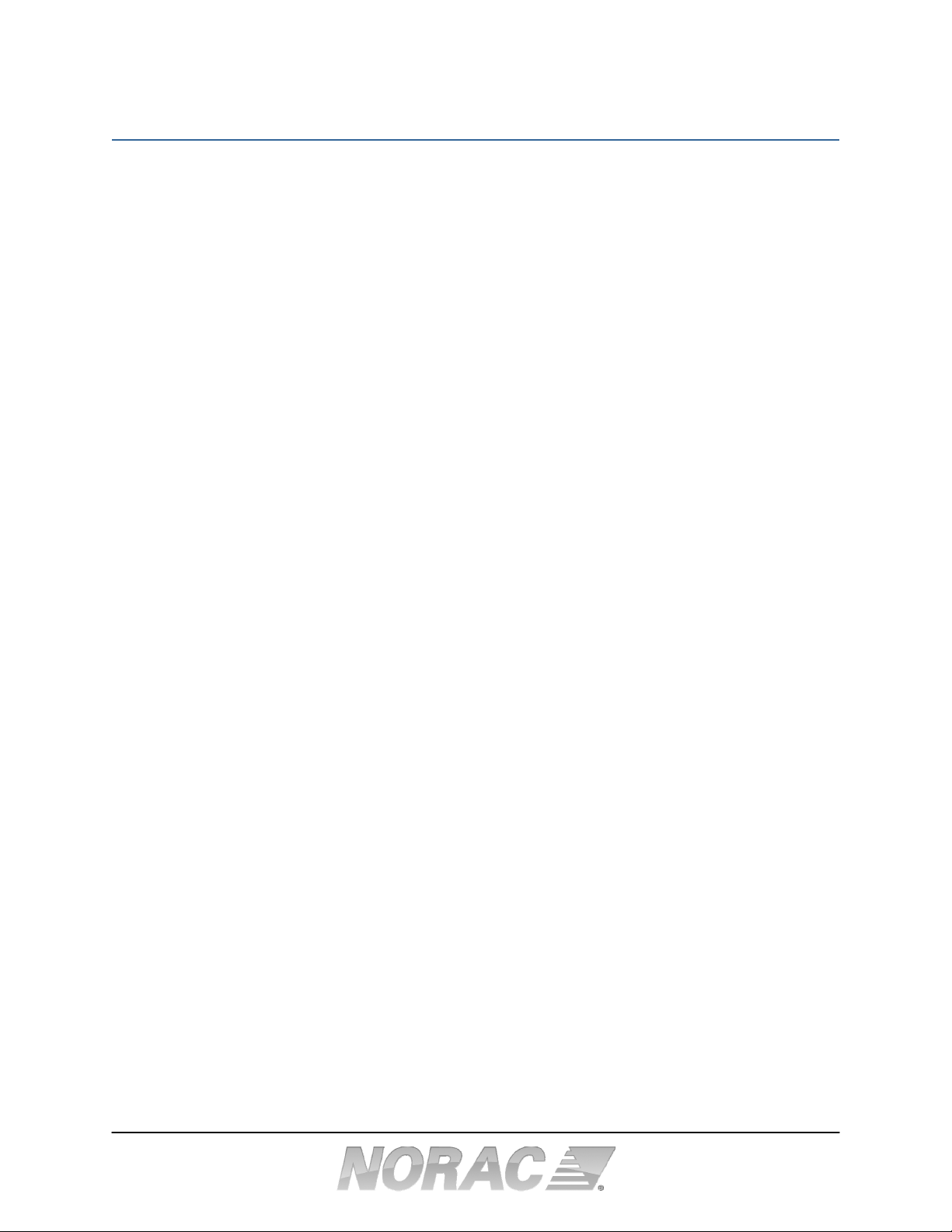

3.2 Hydraulic Plumbing

Figure 3: RG2/RG6 Hydraulic Plumbing

5

3.3 List of Parts

Item Part Number Name Quantity

B05 44706-01 KIT CABLE TIE BLACK 10 PCS 21 IN 150 PCS 7.5 IN 1

B10 44728 MOUNTING BRACKET COMPLETE UC4 BREAKAWAY EXTENDED 2

C03 44656D CABLE VALVE VARIABLE RATE DT 1

C05 43210-20 CABLE UC5 NETWORK 18 AWG 20M 2

C08 43220-03 CABLE UC5 NETWORK 14 AWG 3M 2

C10 44650-50 CABLE UC4.5 POWER GENERIC SELF-PROPELLED 1

C11 44651-50 CABLE UC4.5 EXTENSION VALVE GENERIC 1

C12 44658-24 CABLE UC4 INTERFACE DT06-2X GND2 1

C30 43250-04 CABLE UC5 BATTERY AMP FUSED 1

E01 45100 UC4.5 BOOM CONTROL PANEL 1

E03 43742 UC5 ROLL SENSOR W TEMPERATURE PROBE 1

E04 43741 UC5 ROLL SENSOR VER. 2 1

E05 43750 UC5 ULTRASONIC SENSOR 2

E11 43765 UC5 NETWORK COUPLER 8-WAY 1

E12 43764 UC5 NETWORK COUPLER 2-WAY 3

E20 43764T UC5 NETWORK COUPLER 2-WAY WITH TERMINATOR 2

M01

UC4.5-BC-MANUAL-

OPERATOR

OPERATOR MANUAL UC4.5 SPRAY HEIGHT CONTROL 1

M02 UC4.5-BC-RG2-INST MANUAL INSTALLATION UC4.5 ROGATOR 64 AND 74 SERIES 1

P03 105882 UC5 NETWORK 6 PIN PLUG 3

V01 44963D VALVE BLOCK ASSEMBLY 2 STATION CC/LS PROP DT 4 BOLT 1

3.4 Optional Main Lift Kit

An optional main lift sensor kit is available for purchase from NORAC.

Part Number Name

4570BC UC4.5 MAIN LIFT OPTION - 44743

6

3.5 Hydraulic Parts - JIC Fittings (RG2)

Item Part Number Name Quantity

H04 44863-06 HOSE ASSEMBLY 122R2-06 40 IN L 6FJX 6FJX90 1

H05 44863-17 HOSE ASSEMBLY 122R2-06 32 IN L 6FJX90 8FJX 1

H07 44863-04 HOSE ASSEMBLY 122R2-06 135 IN L 6FJX 6FJX 1

H08 44863-05 HOSE ASSEMBLY 122R2-06 175 IN L 6FJX 6FJX 1

H20 44865-25 HYDRAULICS FITTING KIT - RG2 1

NOTE: Not all fittings are used for this installation.

Do not use high speed power tools/drills when installing hardware.

The use of dielectric grease is not recommended on any NORAC electrical

connections.

To ensure all stainless steel hardware does not gall or seize apply a light coating of

the supplied Permatex Anti-seize grease to all threaded parts upon installation.

Permatex Anti-seize lubricant is preferred, but other similar anti-seize products

may be used.

7

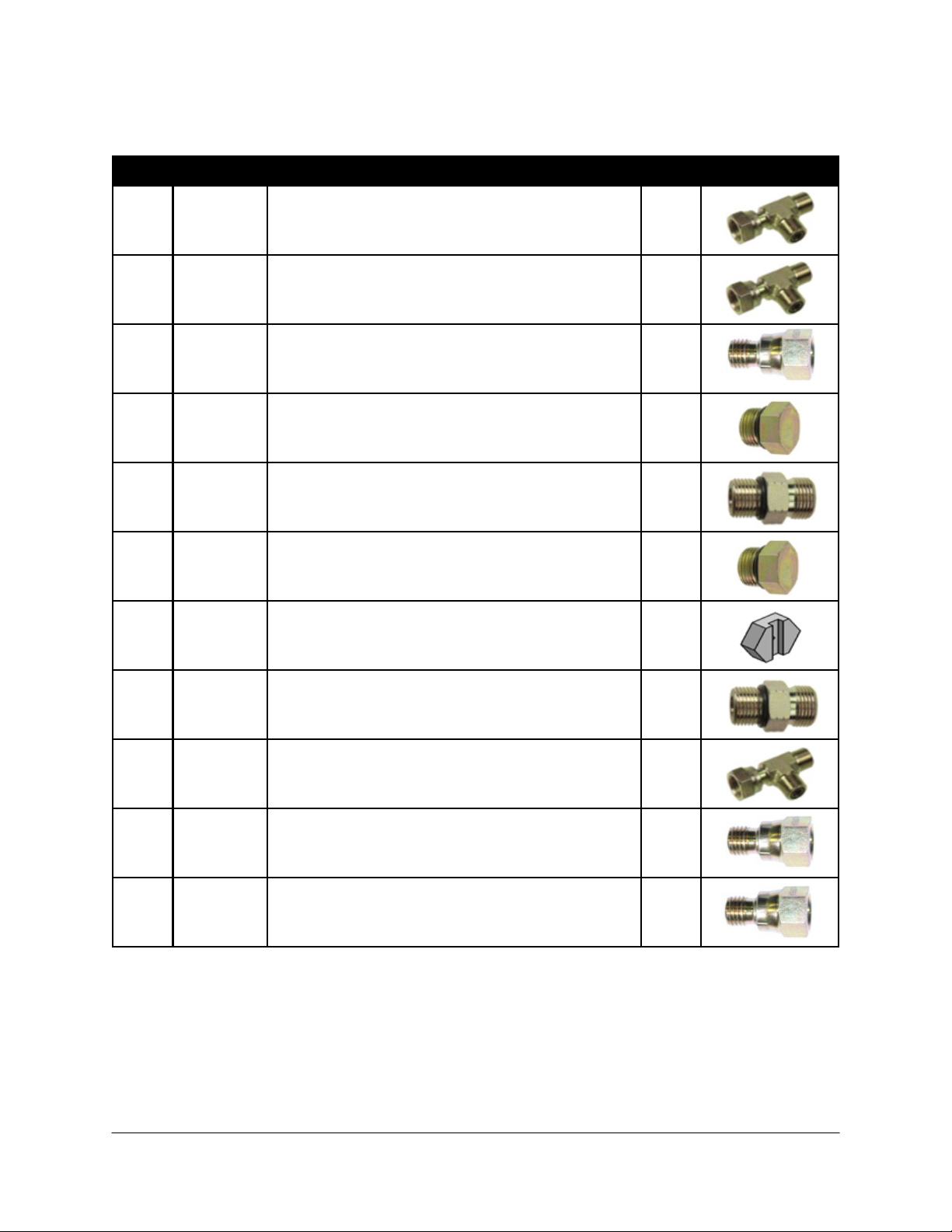

3.6 Hydraulic Fitting Kit Details (P/N: 44865-25)

Item Part Number Name Quantity

Picture

F02 103839 TEE ADAPTER - 6FJXR 6MJT 3

F03 104632 TEE ADAPTER - 8FJXR 8MJT 2

F05 104517 MALE TO FEMALE ADAPTER - 12FJ 6MJ 4

F06 44934 MALE TO FEMALE ADAPTER - 12MJP MACHINED PORT 2

F07 103312 MALE ADAPTER - 6MB 6MJ 4

F08 104369 PLUG - 6MBP 4

F09 44928 ORIFICE INSERT .047 IN ONE WAY 2

F11 104189 MALE ADAPTER - 10MB 8MJ 1

F12 104629 TEE ADAPTER - 12FJXR 12MJT 1

F13 104628 MALE TO FEMALE ADAPTER - 12FJ 8MJ 1

F14 104386 MALE TO FEMALE ADAPTER - 8FJ 6MJ 1

8

3.7 Hydraulic Parts - Flat Faced O-Ring Fittings (RG6)

Item Part Number Name Quantity

H04 44863-48 HOSE ASSEMBLY 122R2-06 40 IN L 6FORX90 6FORX 1

H05 44863-46 HOSE ASSEMBLY 122R2-06 40 IN L 6FORX90 8FORX 1

H07 44863-25 HOSE ASSEMBLY 122R2-06 136 IN L 6FORX 6FORX 1

H08 44863-47 HOSE ASSEMBLY 122R2-06 175 IN L 6FORX 6FORX 1

H20 44865-54 HYDRAULICS FITTING KIT - RG6 1

NOTE: Not all fittings are used for this installation.

9

3.8 Hydraulic Fitting Kit Details (P/N: 44865-54)

Item Part Number Name Quantity Picture

F02 104586 TEE ADAPTER - 6FORXR 6MORT 3

F03 104885 TEE ADAPTER - 8FORXR 8MORT 2

F05 105327 MALE TO FEMALE ADAPTER - 12FORX 6MOR 4

F06 106136 PLUG - 12MORP 2

F07 44917 MALE ADAPTER - 6MB 6MOR 4

F08 104369 PLUG - 6MBP 2

F09 44928 ORIFICE INSERT .047 IN ONE WAY 2

F11 106137 MALE ADAPTER - 10MB 8MOR 1

F12 105338 TEE ADAPTER - 12FORXR 12MORT 1

F13 105732 MALE TO FEMALE ADAPTER - 8MOR 12FORX 1

F14 104884 MALE TO FEMALE ADAPTER - 6MOR 8FORX 1

10

3.9 Alternate Cabling

Some sprayers may require different cabling depending on the connectors used near the valve

block. Please refer to Table 1 and Table 3 for ordering alternate cabling from NORAC.

Table 1: Alternate Interface Cabling Available from NORAC

Item

Replaced Description Connector Type Norac Part #

C12 Interface Cable

W

eatherpack

44658-21

C12 Interface Cable

Metripack 280

44658-32

C12 Interface Cable

Deu

t

sch DT

44658-24

If the sprayer uses a bypass/ jam valve, choose from the Bypass/ Jam Cabling options in Table 2

and Table 3 for ordering bypass cabling from NORAC.

Table 2: Bypass/Jam Cabling Available from NORAC

Item No. Description

Connector Type

Norac Part

#

C16 Bypass Cable

W

eatherpack

44658-34

C16 Bypass Cable

Metripack 280

44658-33

C16 Bypass Cable

Deutsch DT

44658-27

Table 3: Illustrations of Connector Types

Weatherpack

Metripack 280

Deutsch DT

11

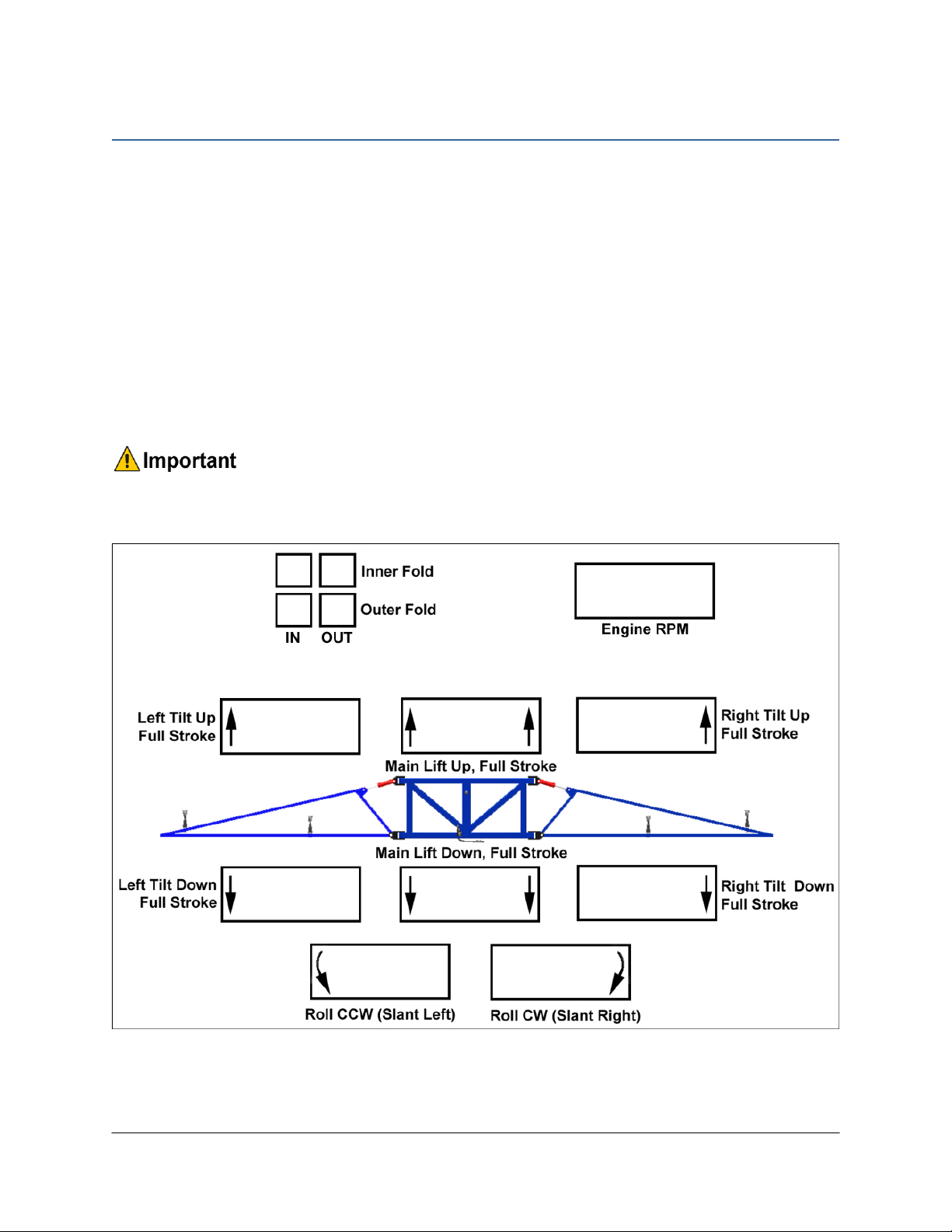

4Pre-Install Checklist

The pre-install checklist is necessary to check the existing sprayer functionality before the

installation.

1. Unfold the sprayer over a flat, unobstructed area (i.e. no power lines…etc.).

2. Ensure all boom-fold operations are functional (place a check mark in boxes below).

3. Bring engine to field-operational RPM and record below.

4. Record the time (seconds) it takes for a full stroke for all boom functions. To ensure

repeatable measurements, take the average of 3 trials.

5. Not all sprayers will have the functions listed below in Figure 4.

Ensure the boom has sufficient travel so it does not contact the ground during

these tests.

Figure 4: Pre-Install Boom Speeds

12

5Ultrasonic Sensor Installation

5.1 Bracket Assembly

Assemble the breakaway sensor bracket as illustrated in Figure 5, following the instructions

below.

Figure 5: Breakaway Bracket Assembly

1. Compress the spring and insert it together with the collar into the base.

2. Slide the tube through the assembled part.

3. Using the bolt and nut, tighten the collar to the tube with the sensor tube centered.

4. Apply a small amount of grease to the rotating surfaces of the bracket.

13

5.2 Ultrasonic Sensor Serial Number Arrangement

When installing the sensors, start with the smallest serial number on the left-hand side, and

proceed to the largest serial number on the right hand side. Each sensor has a serial number

stamped on the sensor housing.

Apply a light coating of the supplied Permatex Anti-seize grease to all threaded

parts upon installation.

Figure 6: Sensor Serial Number Arrangement

14

5.3 Ultrasonic Sensor Mounting Guidelines

The following guidelines will ensure optimal sensor performance and prevent sensor

measurement error. These rules should be followed for both the wing sensors and the main

lift (middle) sensor.

1. In its lowest position, the sensor must be 9 inches (23 cm) or more from the ground (A).

2. The centerline of the acoustic cone should be approximately vertical at normal operating

heights (A).

3. The bottom of the sensor must be at least 9 inches in front of the spray nozzles and boom

structure (B). (This does not apply for the main lift sensor)

4. The bottom of the sensor must be at least 9 inches above the spray nozzles (C).

5. Ensure there are no other obstructions with a 12 inch (23 cm) diameter circle projected

directly below the sensor (D).

Figure 7: Sensor Mounting Guidelines

15

5.4 Wing Sensor Installation

1. The sensor bracket should be oriented forward (ahead of the boom).

2. Typically the best mounting location for the wing sensor brackets will be near the end of

the boom tips, approximately two feet (60cm) from the end.

3. Depending on the boom design, some breakaway sections will lift upwards as they break

back. If the sensor is mounted to this portion of the boom, the system will force the boom

downwards towards the ground as the boom folds backwards.

4. Mount the NORAC ultrasonic sensor into the sensor bracket and run the sensor cable

through the sensor tube.

A problem can arise if a sensor is not mounted correctly. It is possible for the

sensor to read off of the boom instead of the ground. This may only become

apparent once the controller is switched from soil to crop mode.

Also be careful that the sensor bracket does not collide with any other part of the

boom when the boom is folded to transport position. If possible, mount the sensor

brackets while the booms are folded to ensure they will not cause interference.

Figure 8: Sensor Reading Off Boom

16

6Roll Sensor Installation

6.1 Bracket Assembly

1. Securely mount the roll sensors to the included roll sensor brackets using the #6 machine

screws. Tighten screws to 10 in-lbs (1.1 Nm).

2. The orientation of the mounted roll sensor to the roll sensor bracket will depend on the

bracket mounting. The roll sensor CANbus connector must be pointing towards the right

side of the sprayer (when looking from the rear of the sprayer).

Figure 9: Mounting Roll Sensor to Bracket

Figure 10: Roll Sensor Orientation - Connector Facing Right Wing

17

6.2 Roll Sensor Mounting Guidelines

1. When mounting the roll sensors, mount the roll sensor without the temperature probe on

the boom frame and the roll sensor with the temperature probe on the chassis (non-

pivoting portion of the sprayer).

2. Both roll sensor cables should be pointing towards the right hand wing of the sprayer.

3. Ensure both roll sensor cables provide enough slack to allow sufficient boom roll.

Figure 11: Roll Sensor Mounting (Viewed from the rear of sprayer)

Boom Frame

Chassis

Other manuals for UC4.5

31

Table of contents

Other Norac Paint Sprayer manuals

Norac

Norac UC 4.5 Hagie STS10 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac Rogator 1286C User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual