TABLE OF CONTENTS

1INTRODUCTION ................................................................................................................................. 1

2GENERAL SYSTEM DESCRIPTION .................................................................................................. 2

3PARTS LISTS......................................................................................................................................... 3

4INSTALLATION PROCEDURE.......................................................................................................... 6

4.1DETERMINING THE STYLE OF INSTALLATION................................................................................. 6

4.1.1Electrically Teed Installation...................................................................................................................................................... 6

4.1.2Hydraulically Teed Installation ................................................................................................................................................. 8

4.2WING SENSOR INSTALLATION ..................................................................................................... 10

4.3MAIN LIFT SENSOR INSTALLATION .............................................................................................. 13

4.4ROLL SENSOR INSTALLATION....................................................................................................... 14

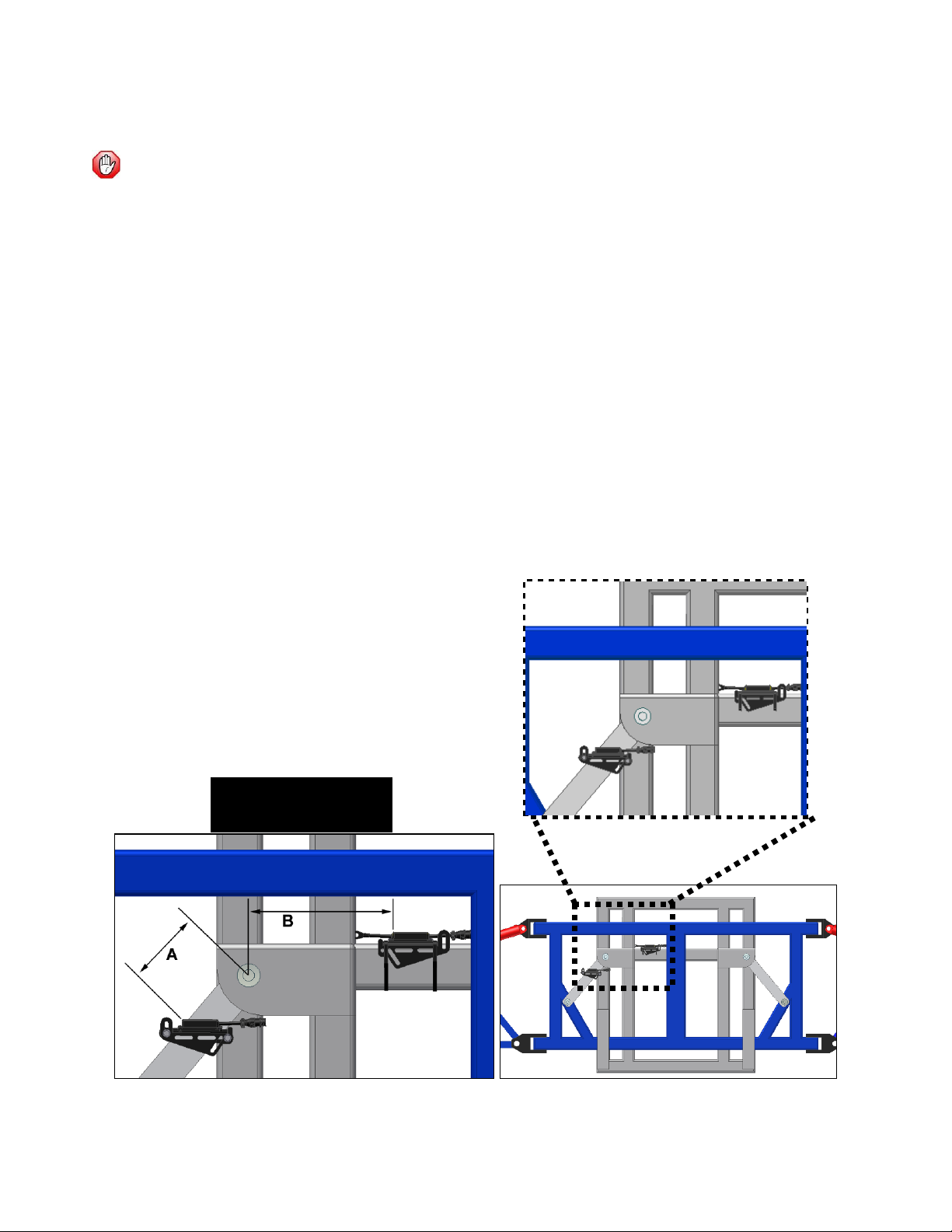

4.4.1Trapeze Style Roll Sensor Installation..................................................................................................................................15

4.4.1Trapeze Style Roll Sensor Installation..................................................................................................................................15

4.4.2Center Pivot Style boom Roll Sensor Installation...............................................................................................................18

4.4.3Inverted Roll Sensor Mounting...............................................................................................................................................20

4.4.4Temperature Probe...................................................................................................................................................................20

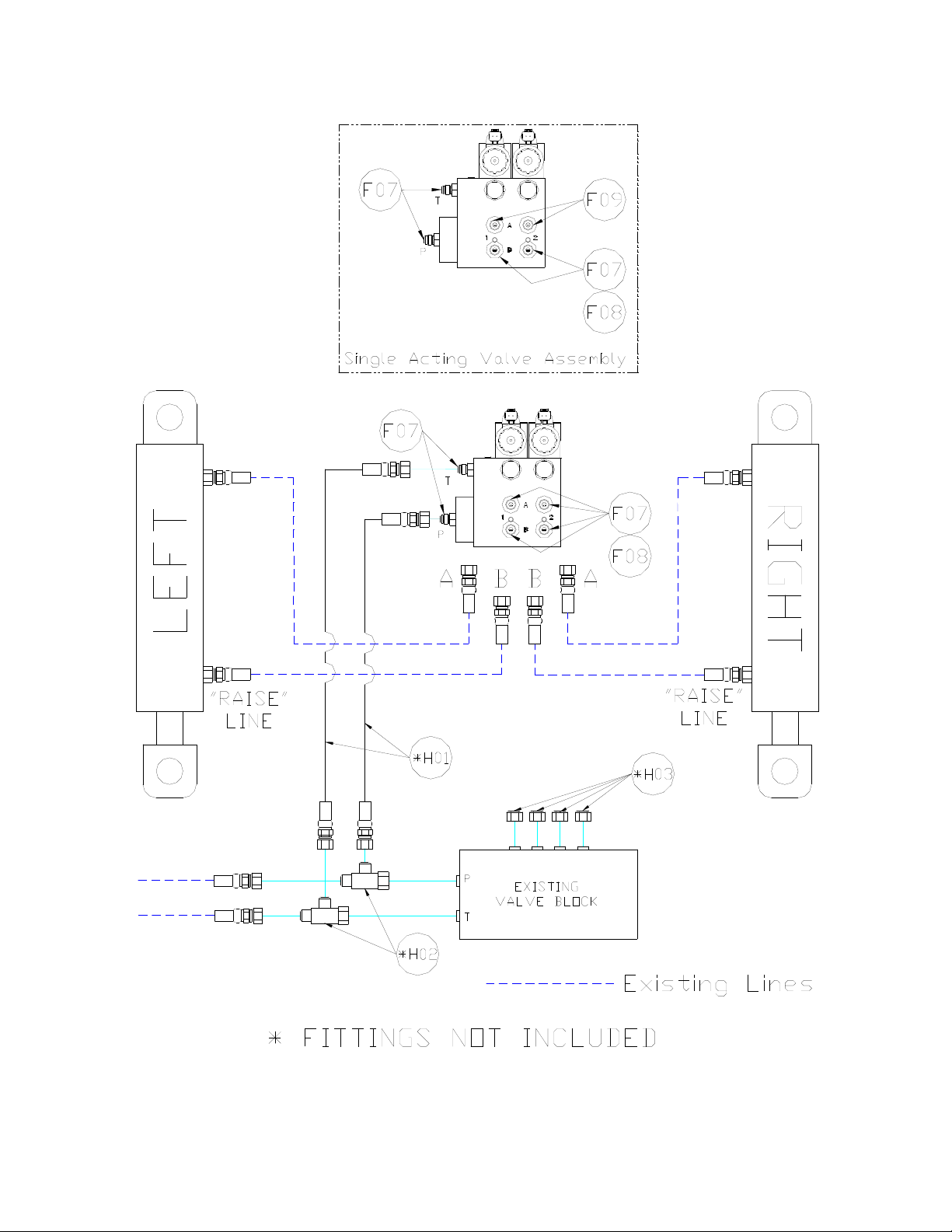

4.5HYDRAULIC INSTALLATION.......................................................................................................... 21

4.5.1Valve Assembly...........................................................................................................................................................................21

4.5.2Valve Mounting ..........................................................................................................................................................................23

4.5.3Hydraulic Plumbing ...................................................................................................................................................................24

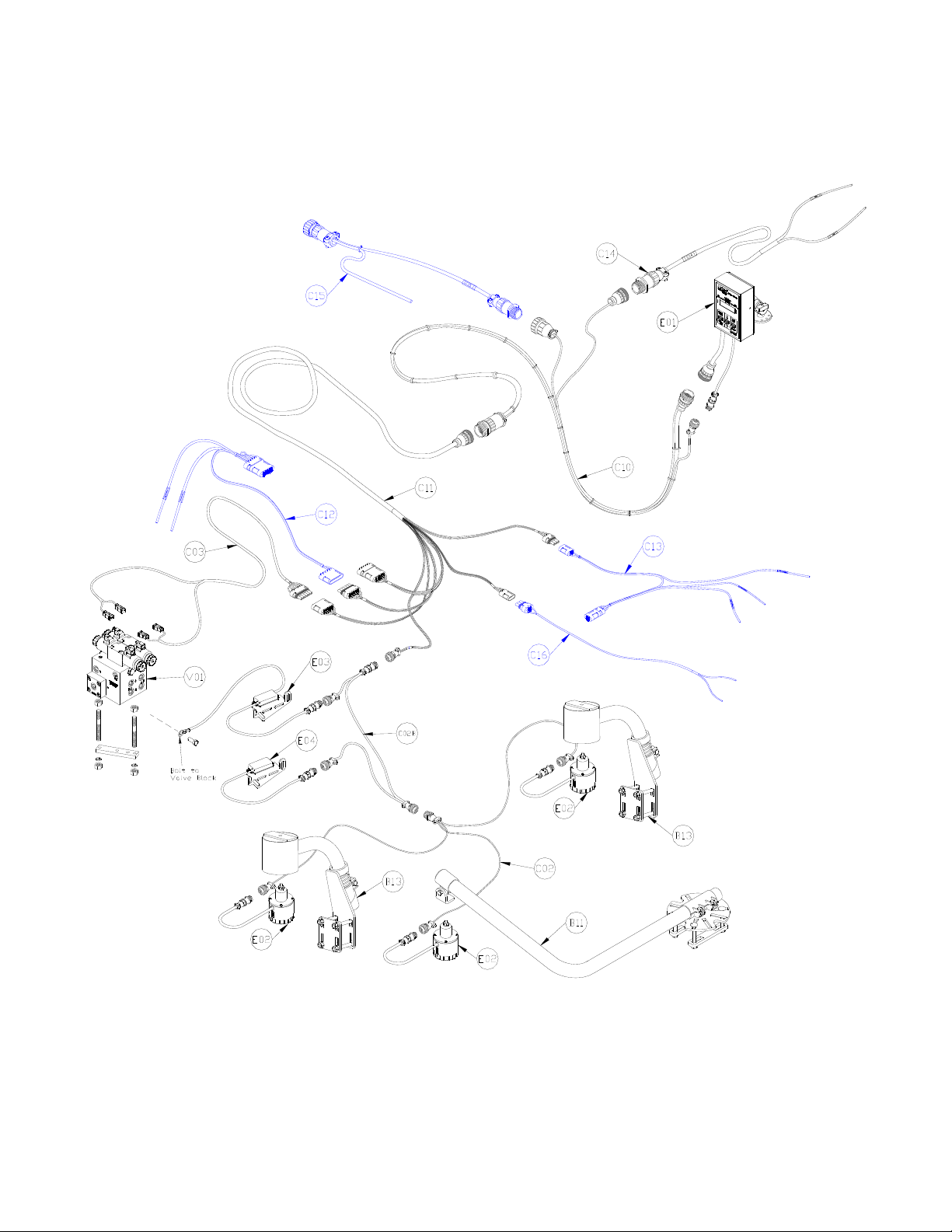

4.6ELECTRICAL INSTALLATION ......................................................................................................... 25

4.6.1Electrical Installation: Electrically Teed...............................................................................................................................27

4.6.2Electrical Installation: Hydraulically Teed ..........................................................................................................................29

4.6.3Finishing the Electrical Installation ........................................................................................................................................30

4.7COMPLETING THE INSTALLATION ................................................................................................ 31

5CALIBRATING THE SLANT VALVE............................................................................................... 32

5.1OVERVIEW .................................................................................................................................... 32

5.2VALVE DEADZONE TEST .............................................................................................................. 33

5.3VALVE GAIN TEST ........................................................................................................................ 34

6ELECTRICAL REFERENCE – CABLE DRAWINGS....................................................................... 35

6.1ITEM C02: 44668 –SENSOR BRANCH CABLE ............................................................................... 35

6.2ITEM C02B: 44664 –CABLE UC4 CAN NODE DUAL.................................................................. 35

6.3ITEM C3: 44656D –CABLE VALVE VARIABLE RATE DT .............................................................. 36

6.4ITEM C10: 44650-35 –CABLE POWER GENERIC PULL-TYPE ....................................................... 37

6.5ITEM C11: 44651-03 –CABLE EXTENSION CABLE VALVE GENERIC ............................................ 38

6.6ITEM C14: 44658-28 –CABLE INTERFACE UC4 BC C14 POWER PIGTAIL .................................. 39