PAGE 8OF 16

ISSUE 1

09 2005

SETTING TORQUE FOR BOLT TIGHTENING______________________________________

STALL TOOLS ________________________________________________________________

These tools use the air pressure set on an external pressure regulator unit to determine the stall torque.

They are supplied with an Air Pressure Graph which relates torque output to air pressure. Set the torque

output as follows:-

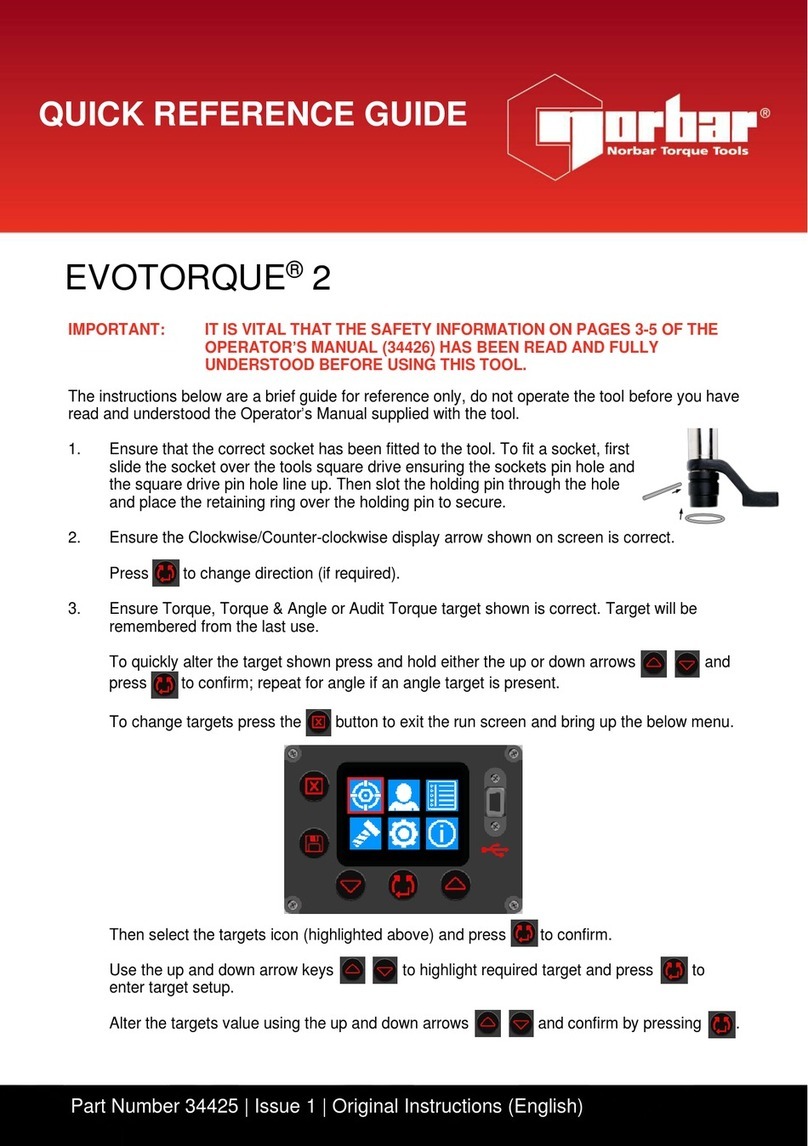

1. Ensure the Clockwise/Counter-clockwise Selector (if fitted) is correctly set.

2. Establish the air pressure required using the Air Pressure Graph.

3. With the tool running, adjust the pressure regulator until the correct figure is shown on the gauge.

IMPORTANT: THE WRENCH MUST BE FREE RUNNING WHILE ADJUSTING THE AIR PRESSURE TO

GIVE THE CORRECT SETTING.

STALL TOOLS FITTED WITH TORQUE REGULATOR ______________________________

The tool can be set in one of two ways.

A. The tool can be set against the Air Pressure Graph in the same way as the stall tool without the internal

regulator as long as the regulator valve is fully open. (This is factory set fully open).

B. To set the torque regulator a suitable calibration device will be required. (see Glossary of Terms) Set the

tool by the following procedure.

1. Ensure the Clockwise/Counter-clockwise

Selector (if fitted) is correctly set.

2. If the tool is connected up to the mains air

supply, switch off the supply and press the

trigger to release any air trapped between

the pressure regulator and the tool. Remove

the air hose from the tool.

3. Fit the adjusting tool J2364 into the air inlet

tube until the box spanner engages onto the

locknut (A). Loosen the locknut (C) by 90

degrees.

4. Engage the screwdriver (D) into the slot in

the end of the valve body (B). Rotate

screwdriver (D) to change torque setting.

5. Tighten locknut (C) and remove adjusting

tool.

6. Re-attach the tool to the air supply and

check the stall torque against acalibration

device. This process may take several

adjustments to achieve the final setting.

7. The tool is now ready for use.

Figure 5