OPERATING INSTRUCTIONS

CAUTION For Your Safety: This jack was designed for jacking purposes

only. After jacking always use safety stands to support the load before

making repairs.

1. Chock the vehicle’s tires that will not be lifted off the ground prior to lifting

the vehicle and if available, apply the emergency brake or any other method

of braking.

2. The air motor (#38) is designed to work at maximum efciency between

85 and 100 p.s.i. system air pressure. It will be necessary to have between 85

and 100 p.s.i. air pressure at the pump in order for the jack to lift its maximum

capacity. DON’T use the air hose (#40) to pull the weight of the jack

as it may cause damage to the ttings and/or air hose. DON’T

neglect

the components, ttings, adapters, and hoses by rough handling of the

jack.

CAUTION For Your Safety: Use jack on hard level surface, center

the load on the saddle (#1) and make sure the setup is stable. Poor operator

judgement and/or unstable setup could cause load to slip off the jack saddle

(#1) and cause personal injury and/or property damage.

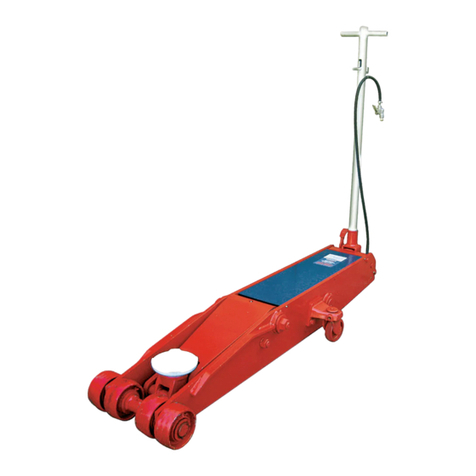

3. Position the jack under the load and determine how much stroke is

required to lift the load to the required height. Any ram stroke used to raise

the extension screw saddle (#1) to the load reduces your lift stroke. The

extension screw saddle (#1) and adapters (#16) are used to make up the

distance between the saddle (#1) and the load so that you will have the most

available hydraulic ram stroke. DON’T use the ram (#5) and/or extension

adapters (#16) without the extension screw saddle (#1) as this could

cause damage to the counterbore of the ram (#5) and adapters (#16).

4. Close the release valve knob (#34) by turning it in a clockwise direction

until it stops and is snug. IMPORTANT: Use the vehicle manufacturer’s

recommended lifting procedures and lifting points before lifting loads.

5. Depress the air valve button (#43) to raise the saddle (#1) to the load.

Before lifting the load make sure the saddle (#1) is centered on the load and

the setup appears stable. If not, reposition the jack and saddle (#1) contact

with the load until the setup is stable. DON’T use the jack in unstable

setup conditions as the load could slip off the saddle (#1) and cause

damage to jack components. DON’T use the entire base assembly

(#17) as a load bearing surface. The only intended load bearing surface

is directly under the hydraulic jack. Using the entire base assembly

(#17) to support the load could cause a bent, broken or deformed base

(#17) and other related jack components. DON’T use front wheels (#19)

for load bearing purposes. They are only designed to transport and

position the jack.

6. Depress the air valve button (#43) to lift the load to the desired height.

During lifting, inspect the position of the jack in relationship to the ground

and the ram in relation to the load to prevent any unstable conditions from

developing. If conditions look like they are becoming unstable, slowly lower

the load and make the appropriate setup corrections after the load is fully

lowered.

7. When the vehicle or load is lifted to its desired height, immediately place

safety support stands (jack stands) in their designated locations and adjust

the stands’ support columns up as close to the designated vehicle support

points as possible. Although jack stands are individually rated, they are to be

used in a matched pair to support one end of a vehicle only. Stands are not to

be used to simultaneously support both ends or one side of a vehicle. Slowly

and carefully turn the release knob in a counterclockwise direction to gently

lower the vehicle onto the safety support stands (jack stands). Make sure

the vehicle is safely supported by the safety support stands’ (jack stands’)

saddles and not the locating lugs of the saddles. Inspect the relationship

of the safety support stands (jack stands) with the ground and the safety

support stand (jack stand) columns and saddles with the vehicle to prevent

any unstable conditions. If conditions look unstable, close the jack’s release

knob and depress the air valve to raise the vehicle off the safety support

stands (jack stands). Make the appropriate setup changes and slowly and

carefully lower the vehicle onto the safety support stand saddles. DON’T

use the jack handle assembly (#46) for purposes other than transporting or

positioning the jack. DON’T use the handle assembly (#46) as a prybar

to dislodge the jack.

8. After the work is done, close the release knob and depress the air valve

until the jack is high enough to remove the vehicle or load from the safety

support stand saddles. Be sure load is stable. If it is not, lower load back onto

safety support stands. Make appropriate setup corrections and repeat the

step again. Remove the safety support stands from under the vehicle being

very careful not to move the vehicle.

9. Turn the release knob in a counterclockwise direction very slowly and

carefully to lower the vehicle or load down to the ground. The jack may be

stored in its normal use position or in a vertical position in order to save

space. DON’T use or store the jack with the handle assembly (#46) end

of the jack pointing or angling down. Loss of uid could render the jack

inoperable. NOTE: The jack is designed with an additional air line (#30) that

adds pressure to the oil in the reservoir and forces the oil into the hydraulic

pump. The air line is vented by way of a hole located in the 1/8 NPT 90°

elbow tting (#35). Oil from the reservoir can seep out of the hole if the jack

is used or stored with the handle assembly (#46) end of the jack pointing or

angling down. Excessive leaking from this hole could reduce the required

oil level in the reservoir and render the jack inoperable. Slight or occasional

leakage from this hole should not cause any concerns.

IMPORTANT: The oil ll level should be no higher than one inch

below the air inlet (#27) on the oil reservoir when the ram (#5) is

completely retracted. Use hydraulic jack oil or turbine oil only.

REPAIR SERVICE

If your Norco product requires service or repair, contact the Norco Customer

Service Department for the location of the nearest Norco Authorized

Service Center.

Norco Industries, Inc.

365 West Victoria St.

Compton, CA 90220

(310) 639-4000 • Fax: (310) 639-7411

www.norcoindustries.com

It will be necessary to provide the Norco Authorized Service Center with

a copy of the bill of sale if requesting warranty repair. If the authorized

service center determines your product is eligible for warranty repair, the

repair will be made at no charge and returned freight prepaid. The cost

of non-warrantable service, repair, and return freight is the customer’s

responsibility.

1. Always store the jack in a well protected area where it will not be

exposed to inclement weather, corrosive vapors, abrasive dust, or any

other harmful elements. The jack must be cleaned of water, snow, sand,

or grit before using.

DAILY

1. Check the condition of all moving parts and replace or repair when necessary.

2. Check the condition of the air hose and replace when necessary.

3. Check for external hydraulic uid leakage and correct the problem immediately.

MONTHLY

All checks mentioned in the “Daily Maintenance and Inspection”

procedures must be conducted.

1. Check and lightly grease the universal joint, the counter-bores of the

ram and 4” extension adapters, the telescopic ends of the 4” extension

adapters, the saddle extension screw threads and the axle. Do not lubricate

any portion of the lift saddle and make sure the saddle is free from grease,

any kind of lubricant, or debris before using the jack.

2. Remove the in-line lter and clean the debris from the lter element and

inside the lter housing.

3. Remove any signs of rust and lubricate the area to inhibit further rusting.

4. It should not be necessary to rell or top off the reservoir with hydraulic

uid unless there is an external leak. An external leak requires immediate

repair which must be performed in a dirt-free environment by qualied

hydraulic repair personnel who are familiar with this equipment. Norco

Authorized Service Centers are recommended. IMPORTANT: In order

to prevent seal damage and jack failure, never use alcohol, hydraulic

brake uid, or transmission oil in the jack. Use Chevron Hydraulic Oil

AW ISO 32 or its equivalent Unocal Unax AW 150.

5. Every jack owner is responsible for keeping the jack label clean and

readable. Use a mild soap solution to wash external surfaces of the jack

but not any moving hydraulic components.

6. Do not attempt to make any hydraulic repairs unless you are a qualied

hydraulic repair person that is familiar with this equipment.

PREVENTATIVE MAINTENANCE

72080 / 72090