OPERATING INSTRUCTIONS

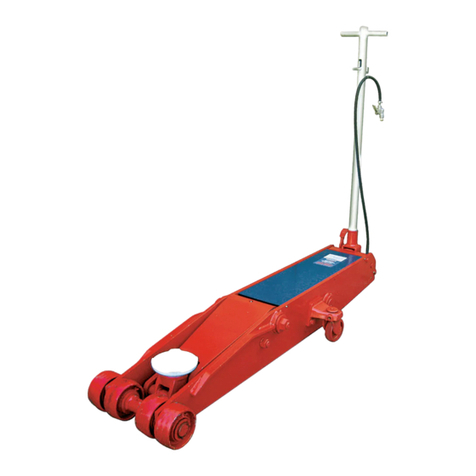

Become familiar with the levers on the “T” handle. The round1.

bar shaped lever is spring loaded and follows a milled out guide

in the tubular handle. The lever should be in the higher position of

the milled out guide in order to activate the “quick rise” cast lever

and pump the “T” handle.

The “quick rise” lever may be pulled in order to activate the2.

“quick rise” feature of the FASTJACK. Pulling the cast lever rotates

the cadmium plated engagement pawl so it can come in contact

with the first available lifting tooth. Once the pawl is in position,

pulling down on the “T” handle engages the pawl with the lifting

tooth. Once the tooth is engaged continue to push down on the

handle and you will see the lift saddle raise. Raise the lift saddle

slowly while simultaneously aligning the saddle with the frame

or component to be lifted. make sure the frame or component is

centered on the lift saddle and not the peripheral edge of the saddle.

If the frame or component is not centered on the saddle, lower the

saddle, reposition the jack and try again. Once the saddle is in

contact with the load, release the cast lever and proceed pumping

the “T” handle or depress the air valve until the load is lifted to the

desired work height.

Lowering the load can only be accomplished by positioning the3.

“T” handle over one of the three holes in the handle base bracket,

disengaging the round bar shaped lever from its high position and

allowing it to drop to the low position, and rotating the lever to the

right. The load cannot be released unless the lever is rotated to

the right.

With the jack in the lowered position, push the jack under the4.

vehicle. IMPORTANT: Use the manufacturer’s recommended

lifting procedures and lifting points before lifting loads.

Pump the “T” handle, or depress the air valve, or use the “quick5.

rise” feature to get the lift saddle close to the load. Now raise the

lift saddle slowly, making sure the saddle comes in contact with

the load, the load is centered on the saddle and the majority of the

load is not supported by the peripheral edge of the lifting saddle at

any single point.

IMPORTANT: Check to see that the ground surface around6.

the jack is free from wheel obstructions such as gravel, tools,

or uneven joints or edges. The jack will have a tendency to

reposition itself during the lifting process and therefore

should not be hindered by wheel obstructions.

Proceed with pumping the “T” handle or depressing the air valve7.

so the load is lifted to the required work height. The “quick rise”

feature is designed to eliminate the pumping time required to bring

the lifting saddle in contact with the load. The “quick rise” feature

was not designed to lift the load. Lifting the load is accomplished

by pumping the “T” handle or depressing the air valve.

After lifting the load, always use approved vehicle support8.

stands with an adequate capacity rating to support the load before

making any repairs or adjustments. Position and adjust the stands

under the load at points that will provide stable support. Lower

the load SLOWLY AND CAREFULLY onto the support stands.

Although support stands are individually rated, they are to be used

in a matched pair to support one end of a vehicle only. Stands are

not to be used to simultaneously support both ends or one side of

a vehicle.

REPAIR SERVICE

If your Norco product requires service or repair, contact the Norco

Customer Service Department for the location of the nearest Norco

Authorized Service Center.

Norco Industries, Inc.

365 West Victoria St.

Compton, CA 90220

(310) 639-4000 • Fax: (310) 639-7411

www.norcoindustries.com

It will be necessary to provide the Norco Authorized Service Center

with a copy of the bill of sale if requesting warranty repair. If the

authorized service center determines your product is eligible for

warranty repair, the repair will be made at no charge and returned

freight prepaid. The cost of non-warrantable service, repair, and

return freight is the customer’s responsibility.

Always store the jack in a well protected area where it will not1.

be exposed to inclement weather, corrosive vapors, abrasive dust,

or any other harmful elements. The jack must be cleaned of water,

snow, sand, or grit before using.

The jack must be lubricated periodically in order to prevent2.

premature wearing of parts. A general purpose grease must be

applied to caster wheels, front axle wheels, elevator arm, handle

base pivot bolts, release mechanism and all other bearing

surfaces. See the exploded view parts drawing for the location of

the above mentioned parts. Failure to maintain proper lubrication

voids warranty.

It should not be necessary to refill or top off the reservoir with3.

hydraulic fluid unless there is an external leak. An external leak

requires immediate repair which must be performed in a dirt-

free environment by qualified hydraulic repair personnel who are

familiar with this equipment. Norco Authorized Service Centers are

recommended.

IMPORTANT: In order to prevent seal damage and jack

failure, never use alcohol, hydraulic brake fluid, or

transmission oil in the jack.

Every jack owner is responsible for keeping the jack label clean4.

and readable. Use a mild soap solution to wash external surfaces

of the jack but not any moving hydraulic components. Contact

Norco Industries for a replacement label if your jack’s label is not

readable.

Inspect the jack before each use. Do not use the jack if any5.

component is cracked, broken, bent, shows sign of damage, or

leaks hydraulic fluid. Do not use the jack if it has loose or missing

hardware or components, or is modified in any way. Take corrective

action before using the jack again.

Do not attempt to make any hydraulic repairs unless you6.

are a qualified hydraulic repair person that is familiar with this

equipment.

PREVENTATIVE MAINTENANCE

71550E / 71100A