OPERATING INSTRUCTIONS

Lift the vehicle to the desired work height and support the1.

vehicle in accordance with the lift manufacturer’s recommended

support procedure and the warnings given in this manual.

Use an under hoist stand rated greater than the weight of the2.

engine to support the engine before unbolting the transmission

from the engine.

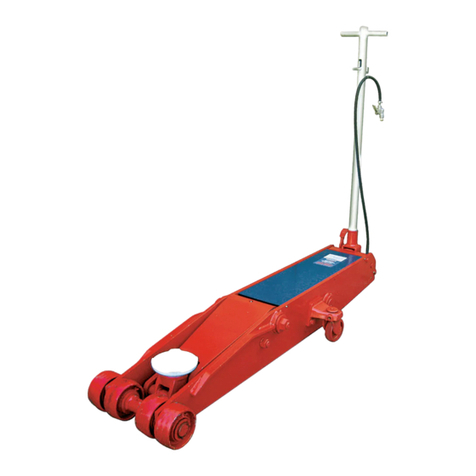

Position the transmission jack directly under the transmission.3.

Turn the release valve knob in a clockwise direction until tight.

Pump the jack to raise the saddle to a height very close to the

center of balance point of the transmission oil pan but do not touch

the transmission.

Adjust the saddle base and containing angles so the ange of 4.

the transmission pan will rest on the top edges of the containing

angles. The containing angles must then be secured to the

saddle by tightening the hex head screws. Now gently raise the

saddle so the containing angles are supporting the transmission

pan ange. Fore and aft saddle tilt adjustments are sometimes

necessary to properly position the transmission on the saddle.

Side to side tilt positioning may be necessary for the same reason

and can be accomplished by activating the side to side tilt handle.

IMPORTANT: Do not put excessive pressure on either tilt

handle to activate the tilt screws. Stop turning the handles

when the threaded trunions or their cast brackets that contain

them come close to contacting the slave trunions or the cast

brackets that contain them.

The restraint chains should be anchored to the containing5.

angles on one side. The loose ends of the chains should be pulled

over the center of balance portion of the transmission and secured

to the two remaining containing angles. The chains should then be

tightened to secure the transmission to the saddle.

Remove the transmission from the engine according to6.

instructions in the vehicle service manual.

Once the transmission has been disconnected from the engine,7.

turn the release valve knob in a counterclockwise direction very

slowly to make sure the jack’s saddle and transmission do not

hang up on any undercar components, wiring, fuel lines, etc. Once

everything is clear continue to lower the jack all the way down.

REPAIR SERVICE

If your Norco product requires service or repair, contact the Norco

Customer Service Department for the location of the nearest Norco

Authorized Service Center.

Norco Industries, Inc.

365 West Victoria St.

Compton, CA 90220

(310) 639-4000 • Fax: (310) 639-7411

www.norcoindustries.com

It will be necessary to provide the NorcoAuthorized Service Center

with a copy of the bill of sale if requesting warranty repair. If the

authorized service center determines your product is eligible for

warranty repair, the repair will be made at no charge and returned

freight prepaid. The cost of non-warrantable service, repair, and

return freight is the customer’s responsibility.

Always store the jack in a well protected area where it will not1.

be exposed to inclement weather, corrosive vapors, abrasive dust,

or any other harmful elements. The jack must be cleaned of water,

snow, sand, or grit before using.

Lubricate moving parts once a month with a general purpose2.

grease.

It should not be necessary to rell or top off the reservoir with 3.

hydraulic uid unless there is an external leak. An external leak

requires immediate repair which must be performed in a dirt-

free environment by qualied hydraulic repair personnel who are

familiar with this equipment. NorcoAuthorized Service Centers are

recommended. IMPORTANT: In order to prevent seal damage

and jack failure, never use alcohol, hydraulic brake uid, or

transmission oil in the jack.

Every jack owner is responsible for keeping the jack label4.

clean and readable. Use a mild soap solution to wash external

surfaces of the jack but not any moving hydraulic components.

Contact Norco Industries for a replacement label if your jack’s label

is unreadable.

Inspect the jack before each use. Do not use the jack if any5.

component is cracked, broken, bent, shows sign of damage, or

leaks hydraulic uid. Do not use the jack if it has loose or missing

hardware or components, or is modied in any way. Take corrective

action before using the jack again.

Do not attempt to make any hydraulic repairs unless you6.

are a qualied hydraulic repair person that is familiar with this

equipment.

PREVENTATIVE MAINTENANCE

72300