The filter can be inspected visually through the transparent filter cover.

Cleaning the air filter:

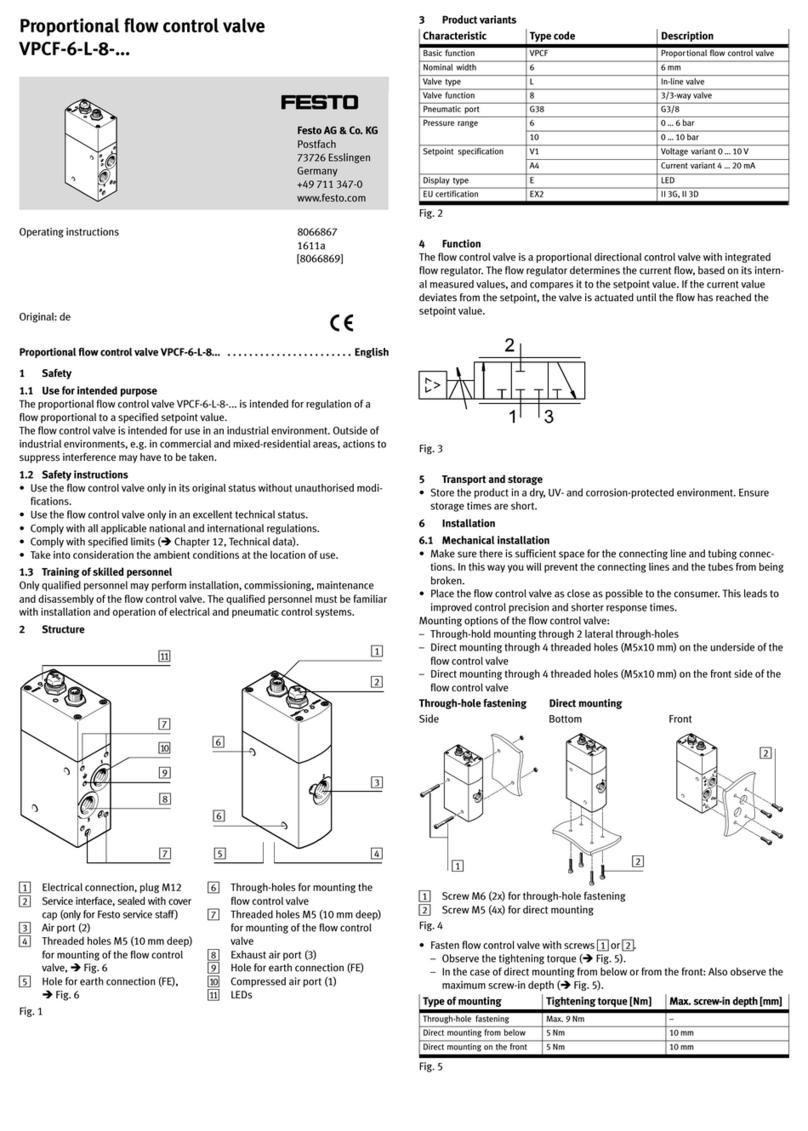

1

2

Fig. 16 Removing/installing the filter

1. Vent the vacuum suction nozzle.

2. Carefully pull out the slide 1of the filter 2up to the first detent. The slide 1

must stay in this position on the filter.

3. Pull the filter out.

(Use a screwdriver to help to bring out the filter, if necessary)

4. Clean the filter 2with cleaner’s solvent, for example.

5. Push the filter 2into its housing using the slide 1.

6. Push in the slide 1.

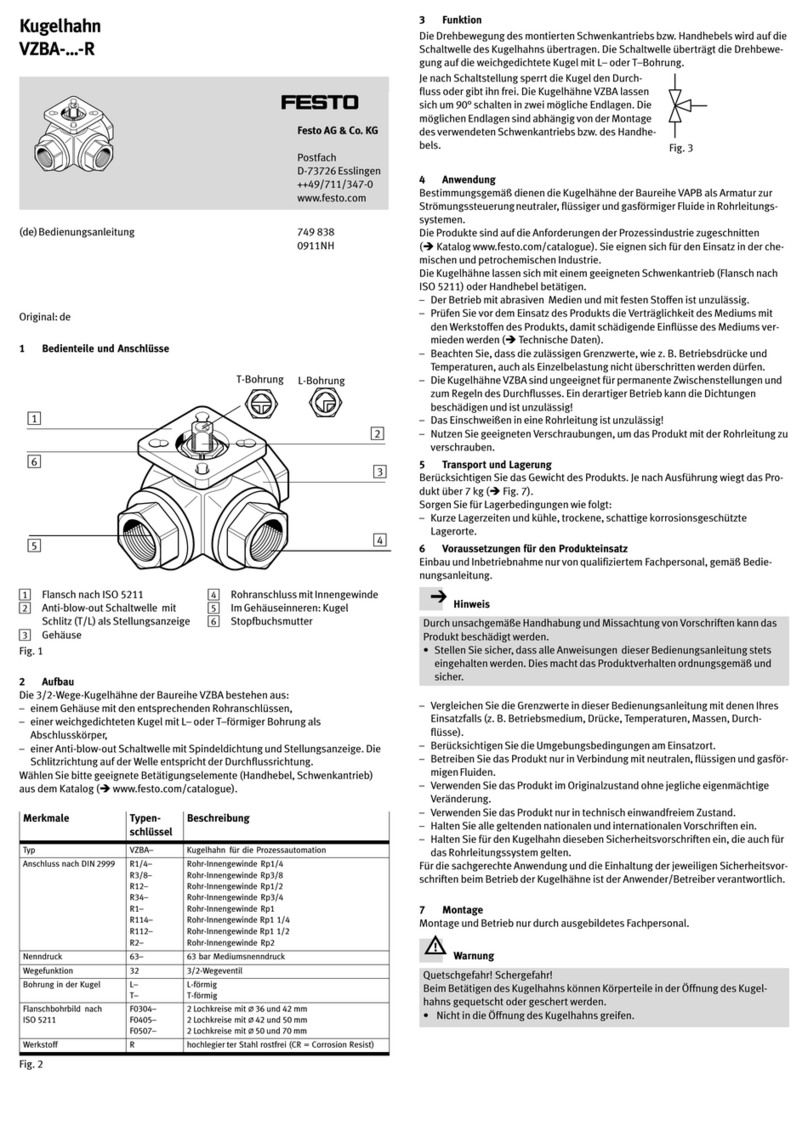

9 Fault clearance

Malfunction Possible cause Remedy

Workpiece does not re

lease from the suction

cup

A vacuum has built up when lift

ing large suction cups quickly

Increase the intensity of the eject

or pulse

Lift the suction cup more slowly

from the workpiece

Actively set the ejector pulse

when lifting the suction cup

Workpiece does not re

lease from the suction

cup

Tubing used between the suc

tion cup and vacuum suction

nozzle is wrongly sized (tube is

too long and/or tube internal

diameter is too small)

Replace hose, for hose require

ments èChapter 5.2

Flow control screw is closed Open the flow control screw

No LED display for switch

ing inputs

Supply voltage not applied or no

permitted operating voltage

Switch on supply voltage / main

tain permitted operating voltage

range

Connections swapped (incorrect

polarity)

Wire the device in accordance

with the connection arrange

ment

No control signal Check the control system

Device defective Replace the device

No LED display for switch

ing output

Pressure failure Eliminate pressure failure

Vacuum suction nozzle operated

with impermissible medium

Replace the vacuum suction

nozzle and operate only with

compressed air

LED display or switching

output does not react in

accordance with the set

tings made

Short circuit or overload at the

output

Eliminate short circuit/overload

Incorrect switching point (e.g. at

0 bar)

Repeat teach procedure

(èChapter 6.2)

Device defective Replace the device

Fig. 17 Fault clearance

10 Disassembly

1. Switch off the following sources of energy before dismantling:

– operating voltage

– compressed air.

2. Disconnect the electrical and pneumatic connections to the vacuum suction

nozzle.

3. Remove the vacuum suction nozzle.

11 Accessories

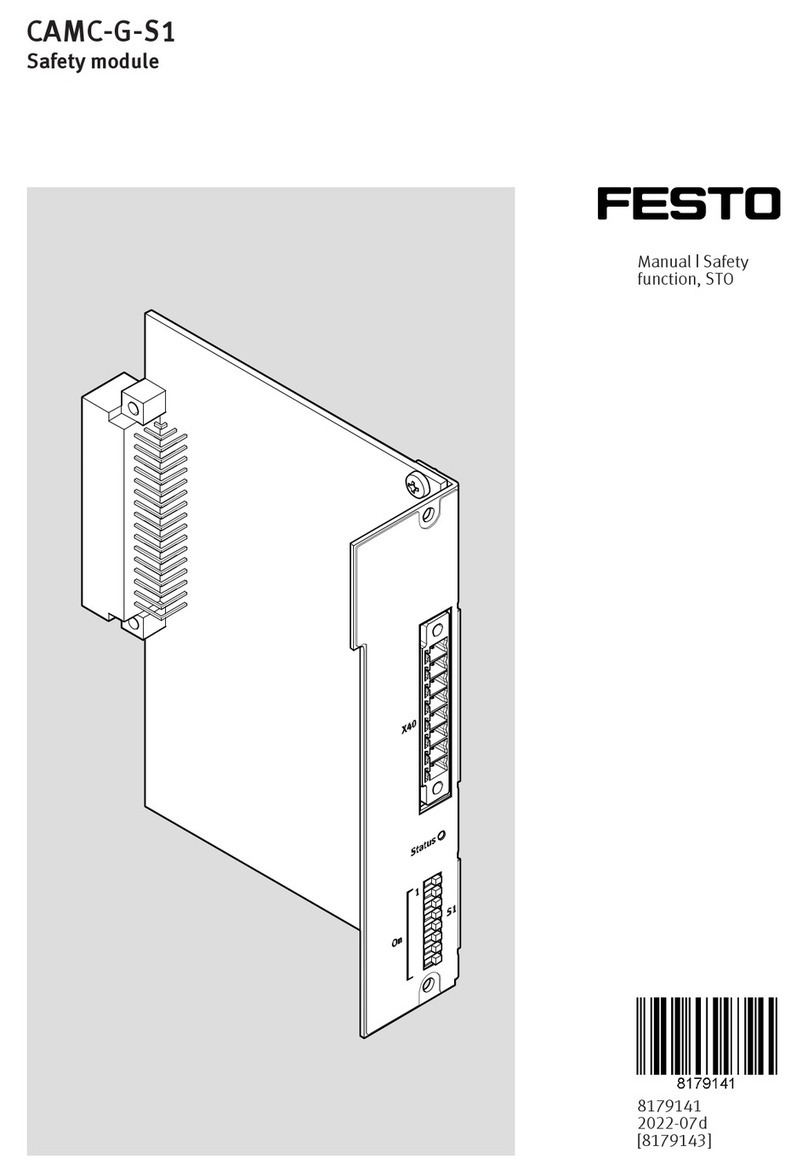

Designation OVEM-05 OVEM-07/10 OVEM-14/-20

Connecting cable M12x1, 5-pin, 2.5 m NEBU-M12G5-K-2.5-LE5

Connecting cable M12x1, 5-pin, 5 m NEBU-M12G5-K-5-LE5

H-rail mounting OABM-H

Mounting bracket HRM-1

Silencer extension – UOMS-¼ UOMS-¼

Common supply manifold OABM-P-4

OABM-P-6

OABM-P-8

Blanking plug OASC-G1-P

Fig. 18 Accessories

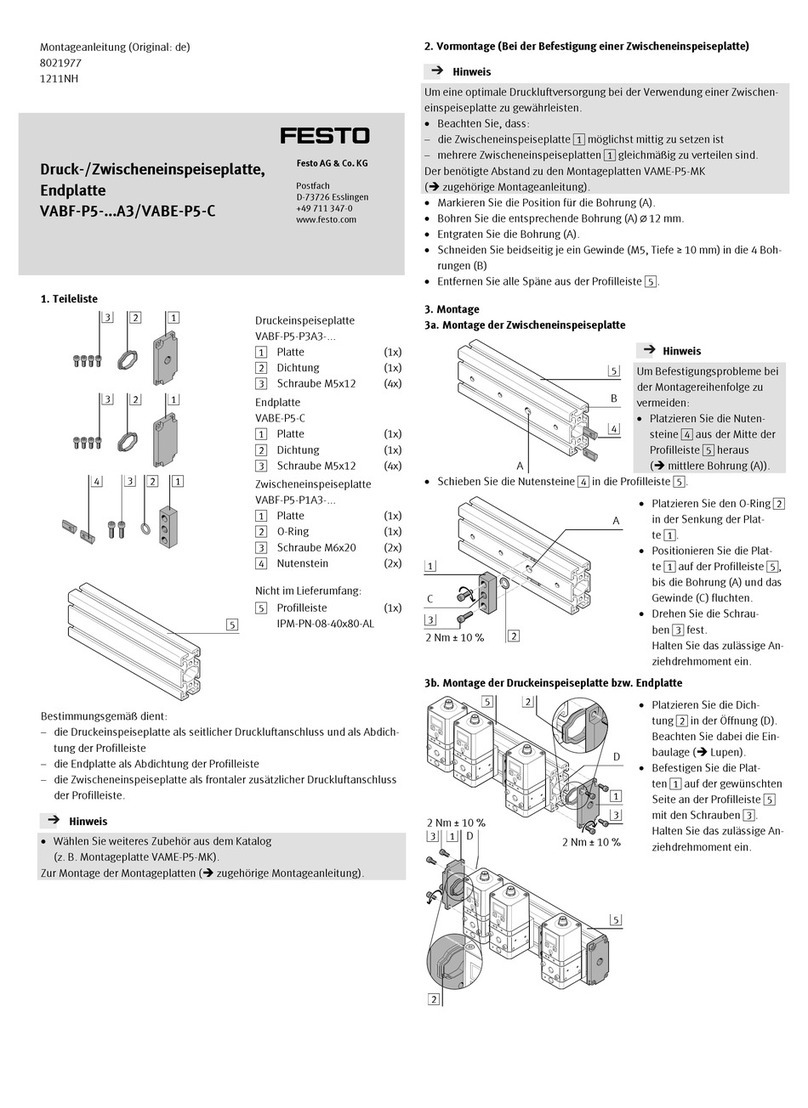

12 Technical data

OVEM -05 -07/-10 -14/-20

Operating pressure [bar] 2 … 8

QS/GN/PL-…-1P/1N: 2 … 6

Operating medium Compressed air to ISO 8573-1:2010 [7:4:4]

Note on the operating medium Lubricated operation not possible

Ambient temperature [°C] 0 … 50

Temperature of medium [°C] 0 … 50

Degree of contamination 3

Relative air humidity [%] 5 … 85

Nominal operating voltage [V DC] 24 ±15 %

Max. current consumption [mA] -1P, -1N: 180

Without vacuum sensor: 30

Idle current1) [mA] 80

Coil characteristics 24 V DC [W] Low-current phase: 0.3

High-current phase: 2.55

Time until current reduction [ms] 80

Ready-state delay [ms] 500

Switching output

– Max. output current [mA] 100

– Voltage drop [V] 1.5

– Capacitive load maximum DC [nF] 100

Dead time [ms] 12 22 35

Protective functions

– inductive protective circuit Adapted to MZ, MY, ME coils

– Protection against short circuit Yes

– Overload protection Yes

Protection against incorrect polarity For all electrical connections

Insulation voltage [V] 50

Surge resistance [kV] 0.8

Degree of protection IP65

Protection class 3

Resistance to interference See declaration of conformity (www.festo.com)2)

Emitted interference See declaration of conformity (www.festo.com)2)

Vibration resistance in accordance with IEC/EN 60068 part 2-6:

0.35 mm travel at 10 … 60 Hz,

5 g acceleration at 60 ... 150 Hz

Resistance to shocks in accordance with IEC/EN 60068 part 2-27:

30 g acceleration with 11 ms duration (half-sine)

Max. permitted signal line length [m] 30

Overload pressure at vacuum port [bar] 1P/1N: 5

Without vacuum sensor: 10

Pressure measuring range4) [bar] –1 … 0

Repetition accuracy of switching

value3)4)

[% FS] Max. ±0.3

Temperature coefficient3)4) [% FS/K] ±0.05

Threshold value setting range4) [bar] –1 … 0

Hysteresis, permanently set3)4) [mbar] 20

1) Both solenoid valves are actuated

2) The product is intended for use in industrial environments. Measures for interference suppression may

need to be implemented in residential areas.

3) % FS = % of the final value in the measuring range (full-scale)

4) Technical feature only relevant for types with vacuum sensor

Fig. 19 Technical data

12.1 Factory setting

OVEM-...

Out Switching point (SP) –0.4 bar

(Fixed hysteresis (HYS) 20 mbar

Fig. 20 Factory setting