Siemens SINUMERIK 840D Operating instructions

Other Siemens Control Unit manuals

Siemens

Siemens SINUMERIK MC Quick start guide

Siemens

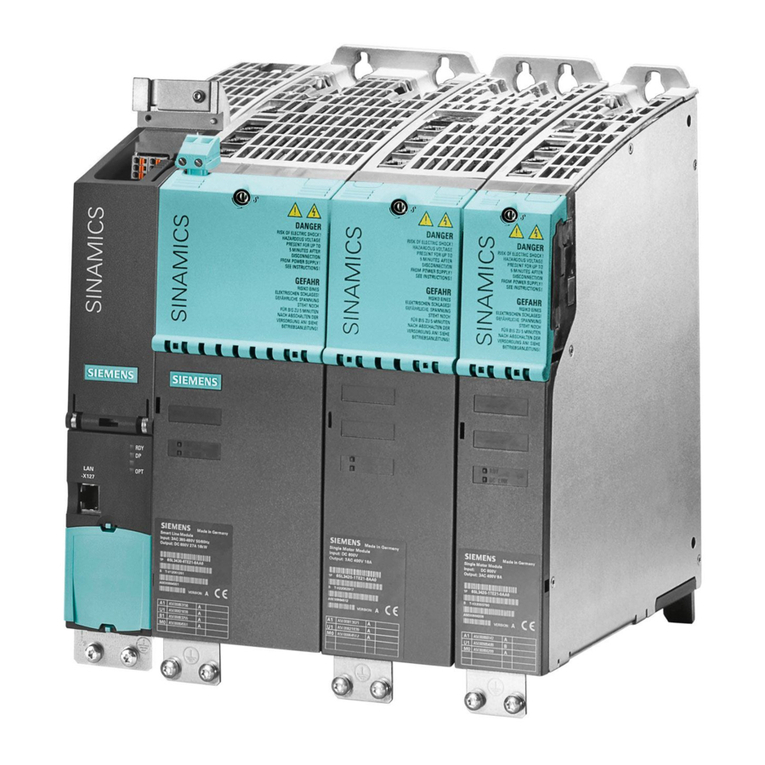

Siemens SINAMICS S120 Technical Document

Siemens

Siemens 3VA9908-0BC Series User manual

Siemens

Siemens Siwarex U Application guide

Siemens

Siemens SINUMERIK 840D sl User manual

Siemens

Siemens SIMATIC CPU 1515SP PC2 F User manual

Siemens

Siemens LAL Series User manual

Siemens

Siemens GAMMA instabus Touch control TC5 User manual

Siemens

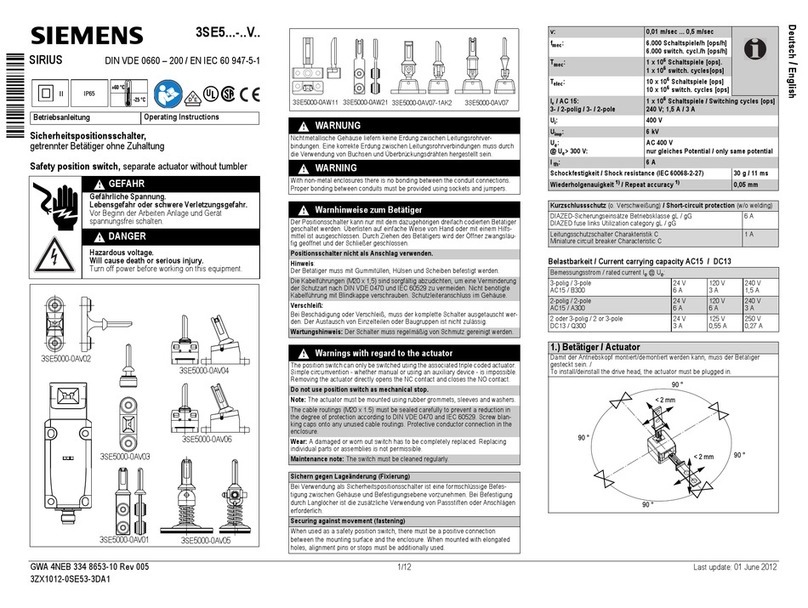

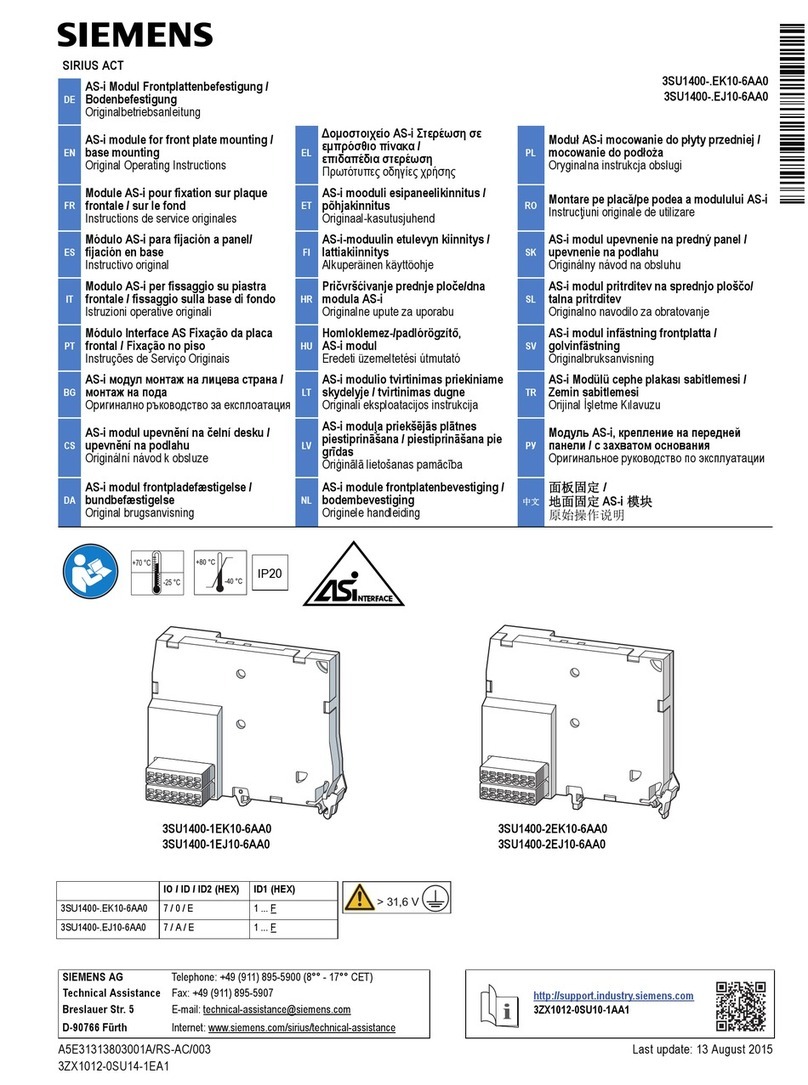

Siemens SIRIUS ACT 3SU1400-1EK10-6AA0 User manual

Siemens

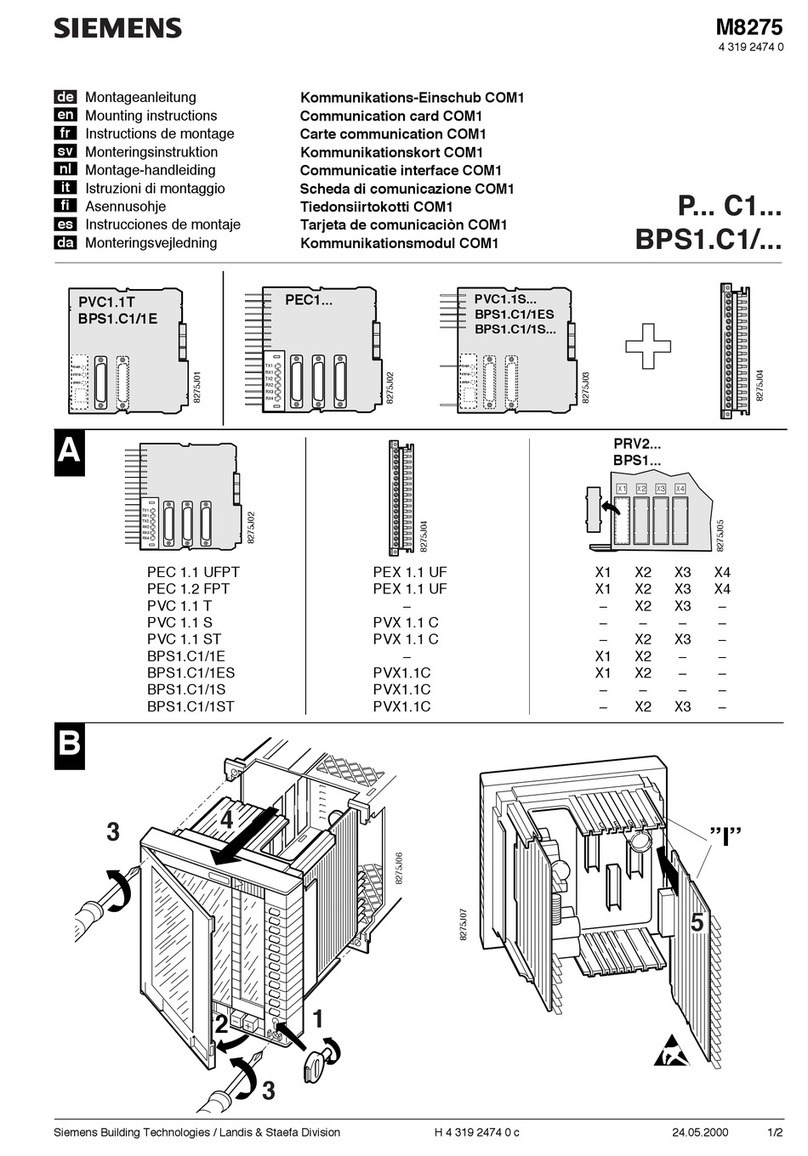

Siemens P Series User manual

Siemens

Siemens SITOP modular 6EP1961-3BA20 User manual

Siemens

Siemens LOGO! CIM User manual

Siemens

Siemens SINUMERIK 840D sl User manual

Siemens

Siemens SINUMERIK 808D User manual

Siemens

Siemens SIRIUS 8WD4428-0B User manual

Siemens

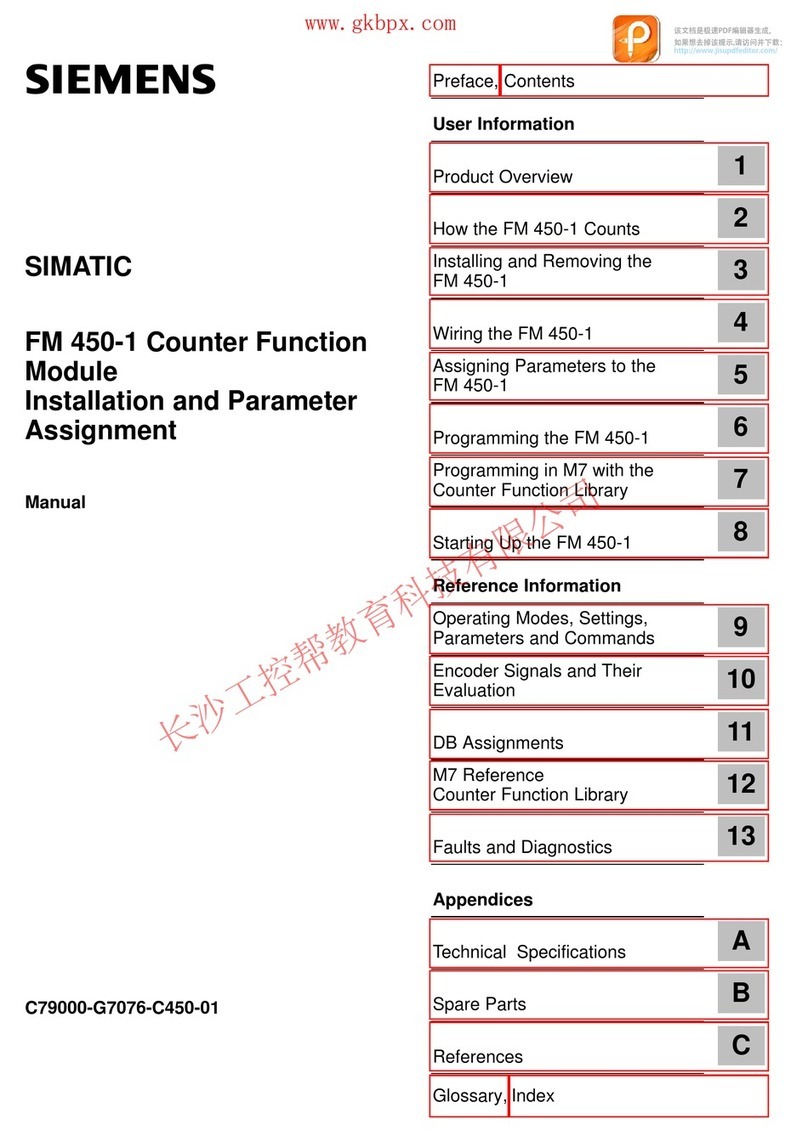

Siemens SIMATIC FM 450-1 User manual

Siemens

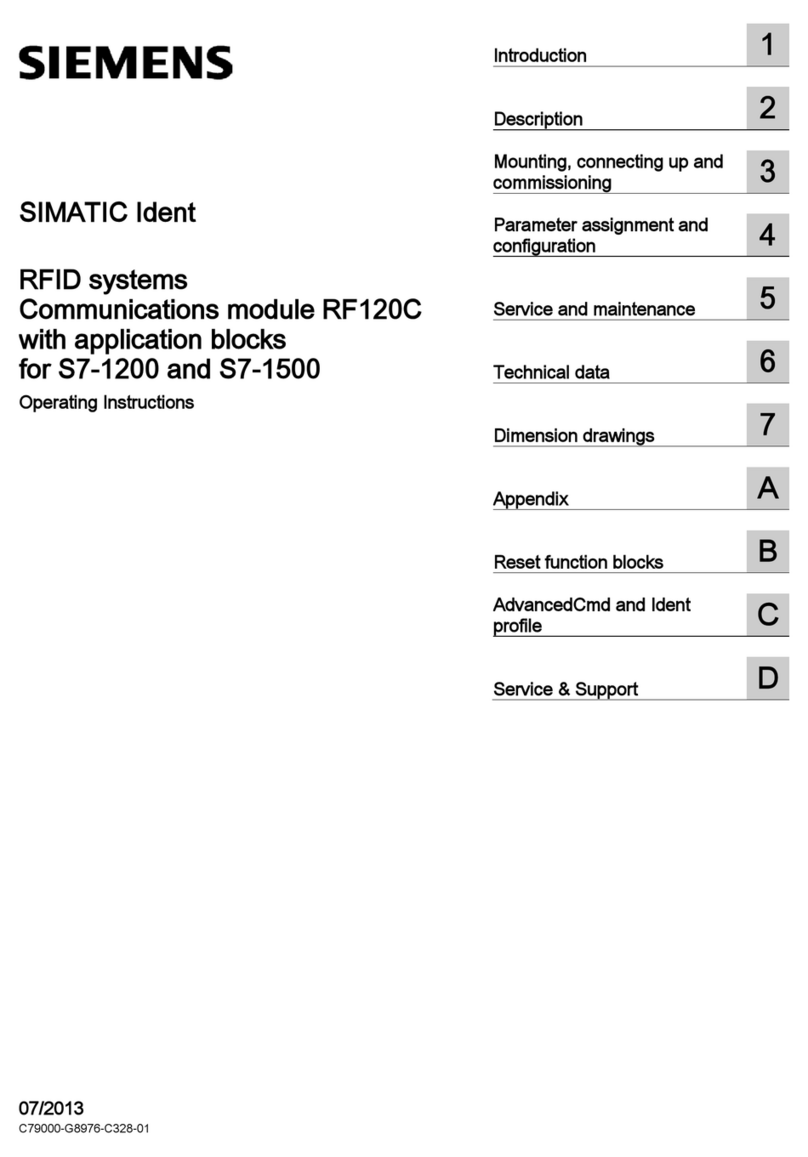

Siemens SIMATIC RF120C User manual

Siemens

Siemens SINAMICS G130 User manual

Siemens

Siemens SINUMERIK 840D Parts list manual

Siemens

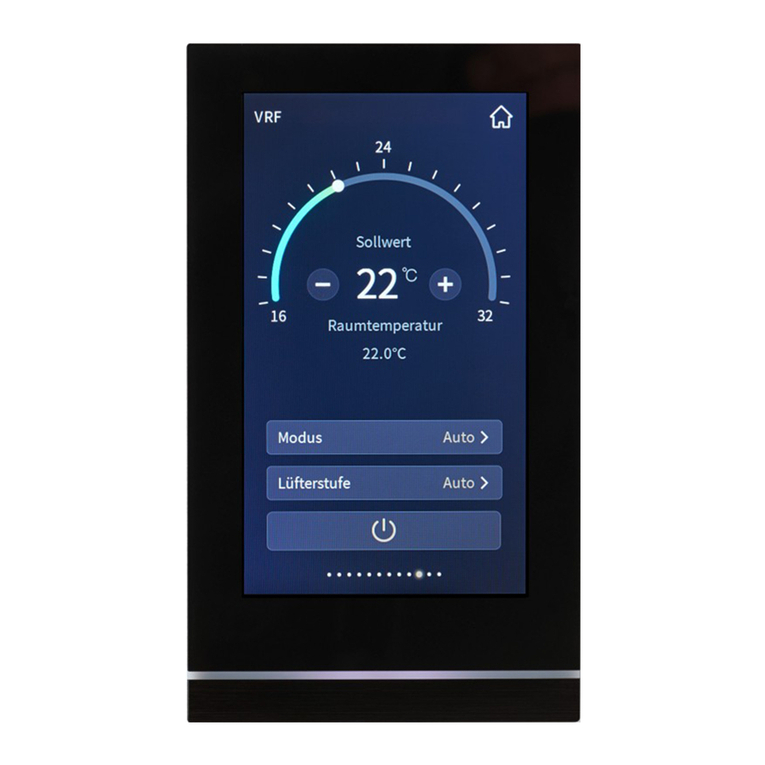

Siemens Climatix POL822 User manual

Popular Control Unit manuals by other brands

Festo

Festo Compact Performance CP-FB6-E Brief description

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

JS Automation

JS Automation MPC3034A user manual

JAUDT

JAUDT SW GII 6406 Series Translation of the original operating instructions

Spektrum

Spektrum Air Module System manual

BOC Edwards

BOC Edwards Q Series instruction manual

KHADAS

KHADAS BT Magic quick start

Etherma

Etherma eNEXHO-IL Assembly and operating instructions

PMFoundations

PMFoundations Attenuverter Assembly guide

GEA

GEA VARIVENT Operating instruction

Walther Systemtechnik

Walther Systemtechnik VMS-05 Assembly instructions

Altronix

Altronix LINQ8PD Installation and programming manual