Preparation

·

Connect the battery/power cable.

·

Install the software located on the USB memorystick. Once the installation is

complete, launch the application related to your instrument.

·

Run a Functional Test, described in the Service Manual chapter in the

Comprehensive Manual.

·

Set the Pressure Offset: On-line > Set Pressure Offset.

·

If there are magnetic materials in proximityto the instrument when mounted, a

calibration of the compass is necessary: On-line > Compass Calibration.

·

Erase the recorder in advance of everydeployment.

Deployment Planning

·

Select Deployment Planning.

·

The activated dialog contains all parameters required to specifythe operation of the

instrument. Adescription of each parameter can be found in the application help,

accessible from the Deployment Planning dialog box. One parameter that requires

extra attention is the Nominal velocity range, which is a simple wayof describing

the maximum unambiguous velocitythe instrument is be able to measure. The

velocityrange should be set as low as possible, to minimize measurement

uncertaintyand noise. If the actual values measured exceed the range, your data

will be impaired and maybecome unusable. See the Comprehensive Manual

(Velocimeters) for more information.

·

The Deployment Planning frame on the right-hand side of the dialog displays

performance parameters that are automatically updated as you change the

settings. Use the Standard configuration to plan your deployment, unless you have

a very good reason to move to Advanced. The latter increases the flexibilitybut so

does the risk of making mistakes. Note that the Use Advanced Settings box

(Standard tab) must be checked for the advanced settings to be effective.

·

When finished, press Update to accept the changes. By using the Open/Save

commands in the File menu (or the corresponding toolbar buttons) the deployment

parameters can be saved to file at any given time and re-loaded when it is time to

deploythe instrument.

Start Recorder Deployment

·

Establish communication with the instrument.

·

Select Start Recorder Deployment, either from the pull-down menu or from the

toolbar.

·

Specifythe date and time to start the data recording.

·

In the Name field, enter up to sixcharacters of text to identifythe data file stored in

the recorder.

·

In the File Comment box, enter up to 180 characters of text that will be included in

the data file for documenting the data set.

·

After pressing OK, the Set Clock dialog box is displayed. We recommend setting

the clock to PC time. The time reference is especially important to ensure proper

synchronization between the instrument and other datasets collected

independently. Time spent on setting the time properlybefore a deployment can

save a lot of time in post processing and analysis.

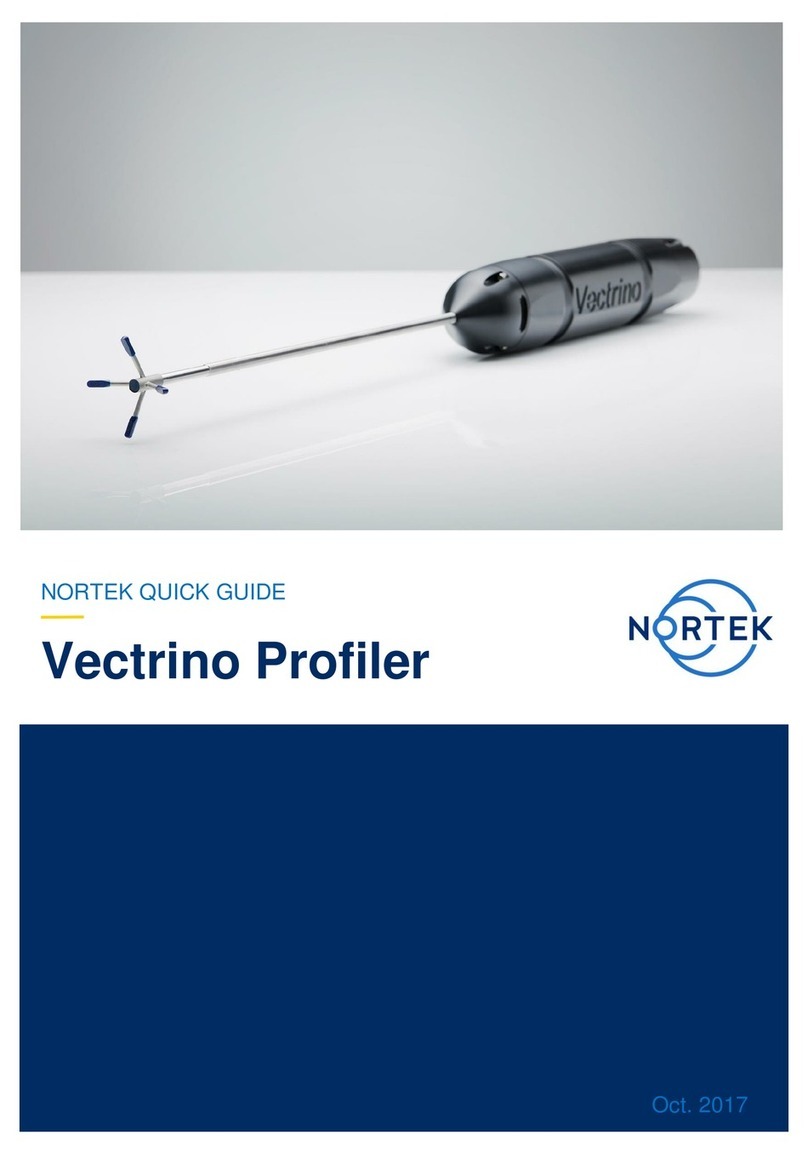

Please check that all

expected items are included

in the shipment:

·

The instrument

·

External pow er/signal cable

·

NORTEK equipment storage

box/toolkit

·

USB to serial converter

·

AC/DC voltage transformer

·

Pow er cable (European or

American)

·

Softw are on USB memory

stick

·

Final test check list

·

Packing list

Install the Nortek software

The instrument’s softw are is

located on the attached memory

stick.

Please check the web regularly

for updates on both softw are

and firmw are.