With the broad brushless power band, you can go 1-2 teeth higher pinion than listed

above for more top speed, but remember going higher will produce excessive ESC & motor

heating. Check the motor’s operating temperature after making any gearing adjustments-

-motors are designed to operate from 160ºF-175ºF. If you do overheat your ESC and

motor, be sure to allow it to cool for several hours and install a smaller pinion gear.

HAVOC 3S GEARING & ADJUSTABLE PARAMETERS

ATTENTION: Correct gearing is essential to getting proper performance from your brushless motor system!

4-2010

#55-1733P-1 Ver. 2

Motor operating temperature is the ONLY

way to properly set the vehicle gearing

The motor should be 160-175°F MAX at end of run!

Change the gearing to avoid overheating.

DO NOT FREE REV OR OPERATE WITHOUT LOAD!

General Gearing for 2 & 3-cell Li-Po or 6 & 9-Cell Ni-MH Use:

These recommendations are for sport or entry level setups. Stock radio equipment

and sport “stick-type” battery packs should work safely. These gearing range

recommendations are intended to provide initial safe operation.

The Havoc 3S’s included fan is required when using a 3S Li-Po battery pack.

Decrease the pinion tooth number by 2-3 for motors without sintered rotors.

If you do not change gearing after switching to brushless, you will be

over-geared and will have slow acceleration & excessive temperatures!

FOR RTR KITS:

Most car kits include a pinion gear that is generally sized for mild motors and is

fairly large. To be safe, replace the installed pinion gear with one that is about 3

to 5-teeth smaller. Most stock spur gears are safe to use.

FOR TRAXXAS® SLASH™:

With a Novak 8.5-turn brushless motor installed, the RTR kit’s included 18-tooth

and 23-tooth pinion gears will provide speeds above 40 mph with various

battery packs. For more specific speed run information and tips to reaching

higher speeds, please visit the Novak Web site.

P5

PROPER GEAR SELECTION

www.teamnovak.com

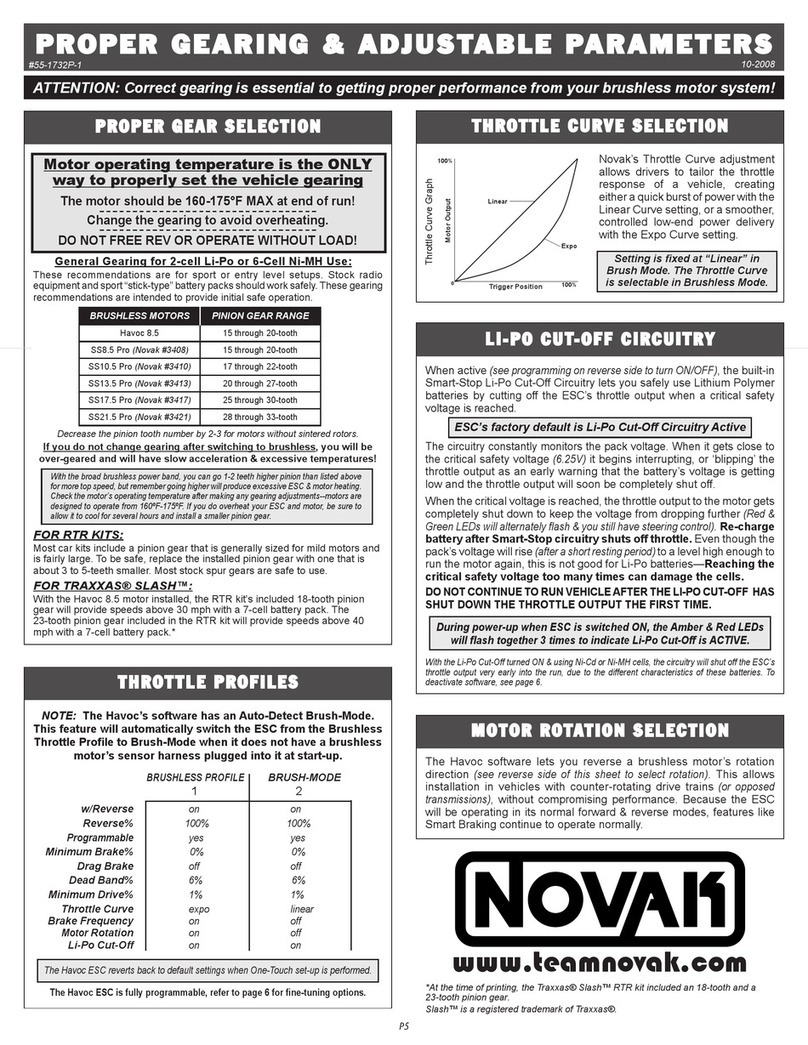

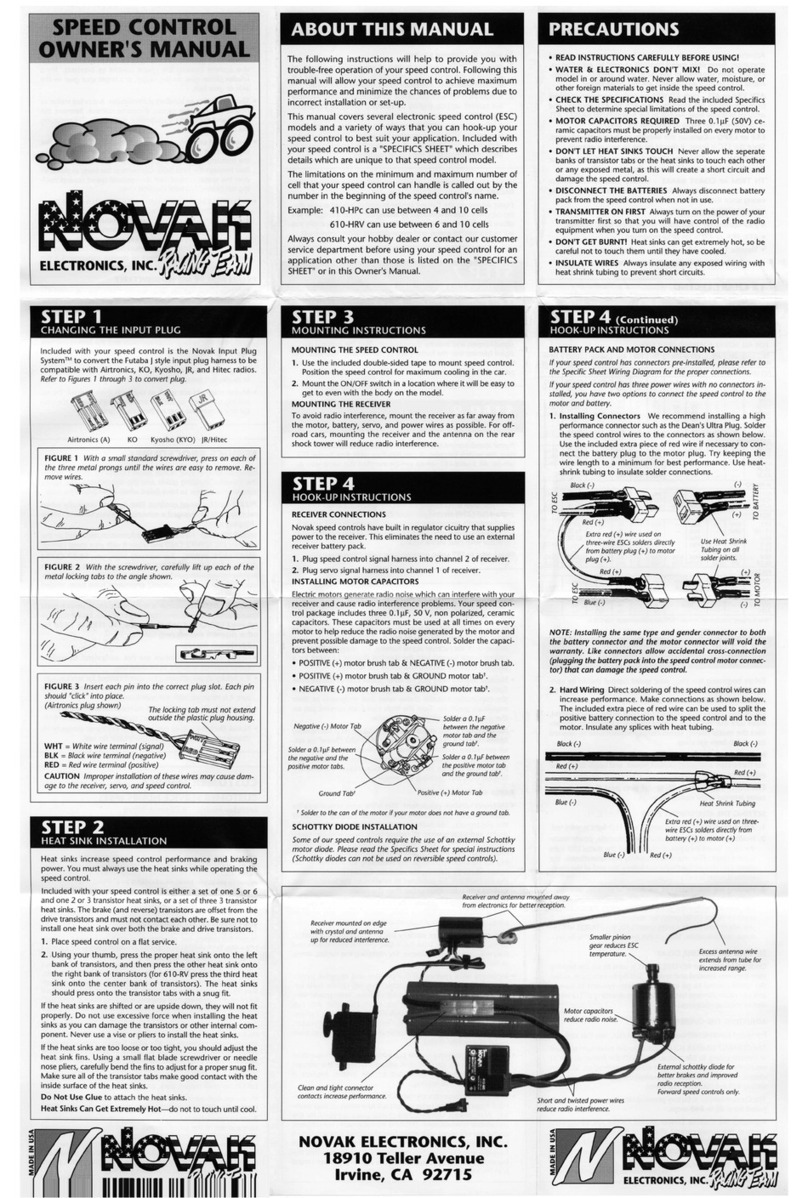

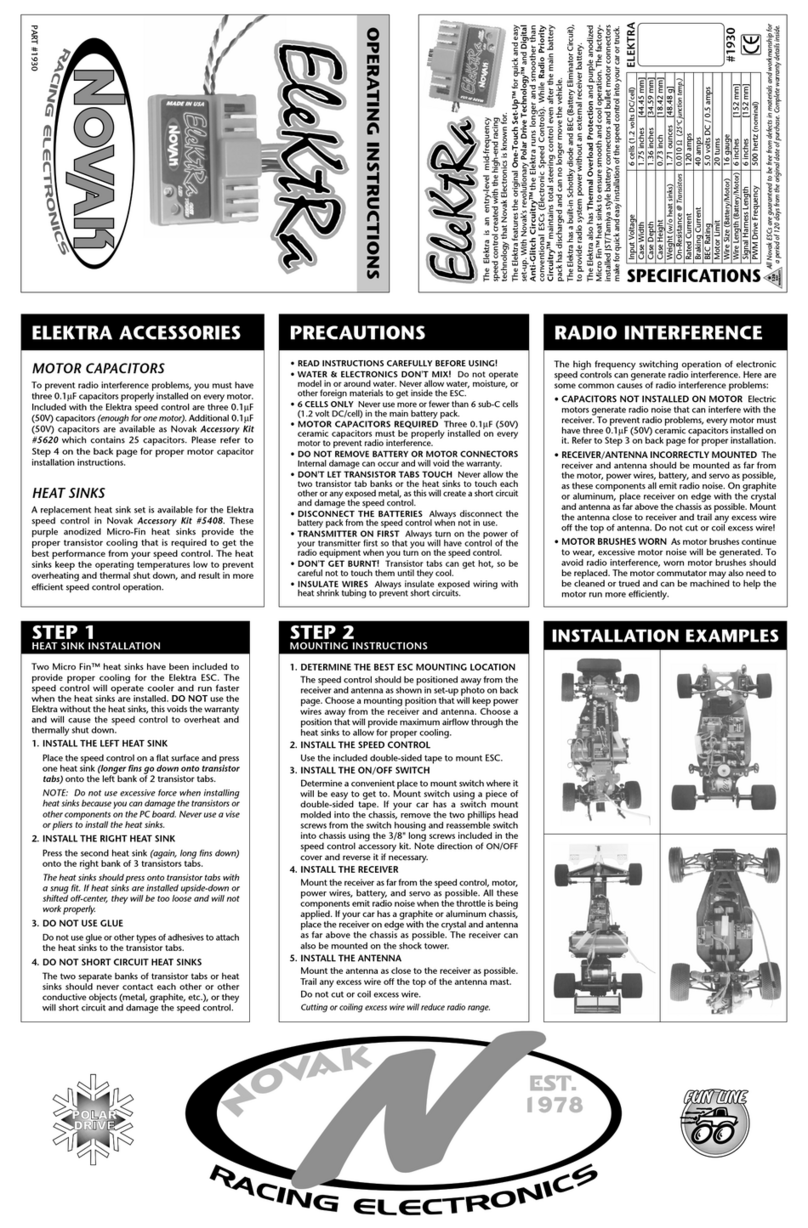

Motor Output

Trigger Position

0100%

100%

Linear

Expo

Novak’s Throttle Curve adjustment

allows drivers to tailor the throttle

response of a vehicle, creating either

a quick burst of power with the

Linear Curve setting, or a smoother,

controlled low-end power delivery

with the Expo Curve setting.

Setting is fixed at “Linear” in

Brush Mode. The Throttle Curve

is selectable in Brushless Mode.

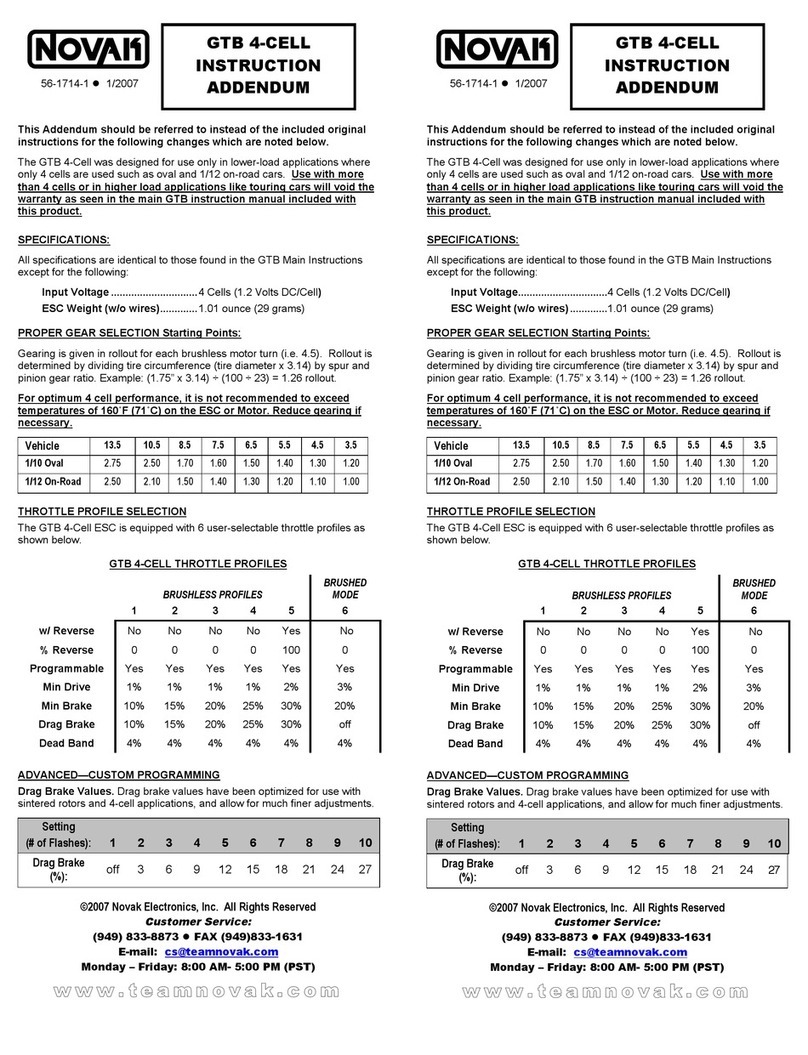

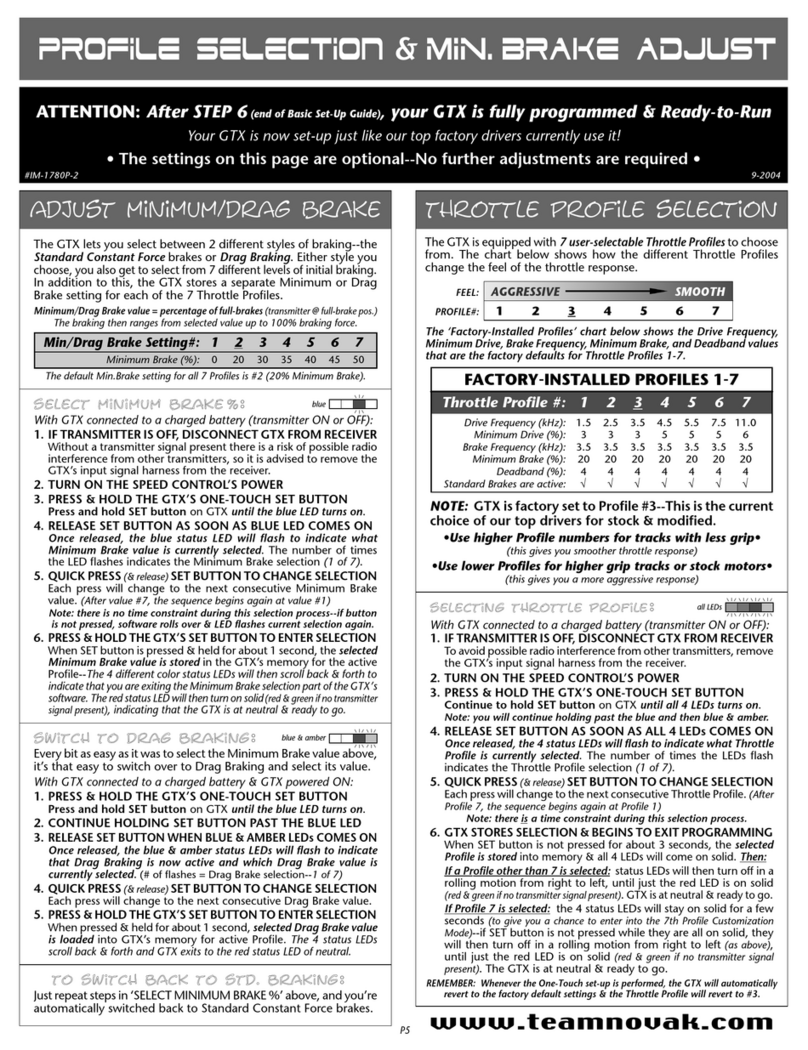

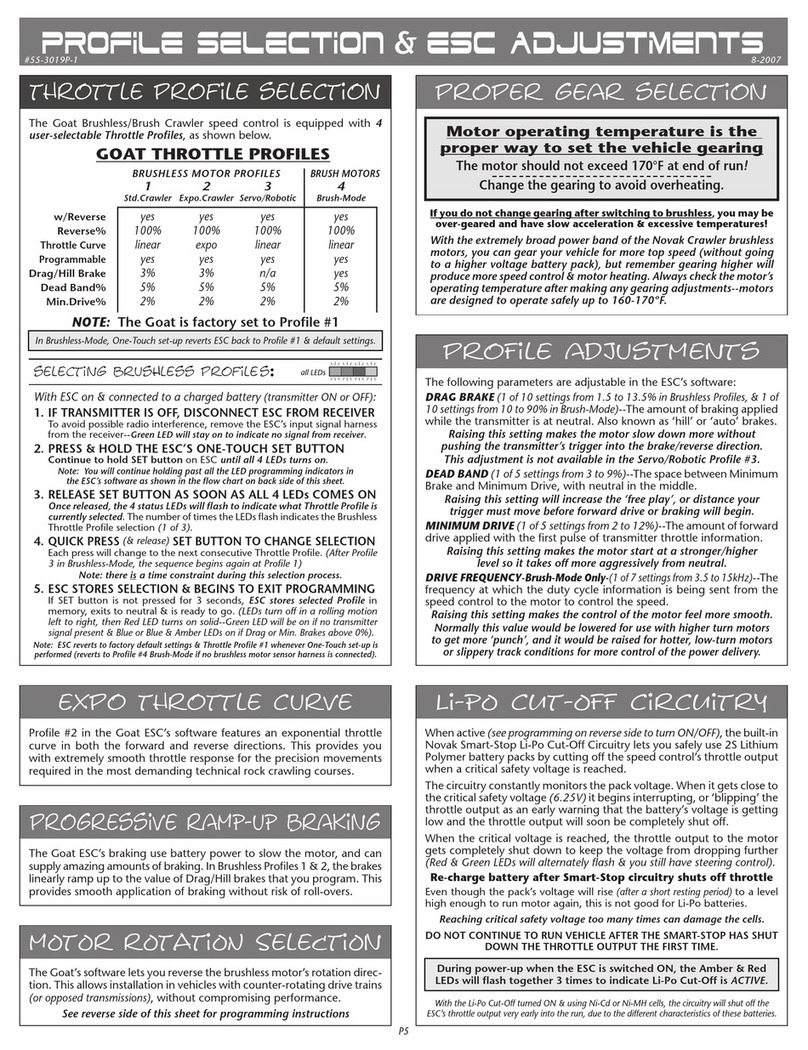

THROTTLE PROFILES

NOTE: The Havoc 3S has the ability to run on either two or three-cell Li-Po

batteries via Novak’s auto detect software. When Li-Po circuitry is active

(see programming on reverse side to turn ON/OFF), it automatically switches

to the proper Li-Po cut-off voltage for the battery packs you connect.

BRUSHLESS PROFILE

BRUSH-MODE

1 2

w/Reverse

on on

Reverse%

100% 100%

Programmable yes yes

Minimum Brake%

0% 0%

Drag Brake

off off

Dead Band%

6% 6%

Minimum Drive%

1% 1%

Throttle Curve

expo linear

Brake Frequency

4 kHz 3 kHz fixed

Motor

Rotation

CCW Q N/A

Li-Po Cut-Off

on on

The Havoc 3S ESC reverts back to default settings when One-Touch set-up is performed.

The Havoc 3S ESC is fully programmable, refer to page 6 for fine-tuning options.

This ESC is compatible with 2-3S Li-Po or 4-9 Ni-MH cells. Novak’s exclusive

Smart-Stop Li-Po Cut-Off Circuitry is built-in and when active (see program-

ming on reverse side to turn ON/OFF), it automatically switches to the proper

Li-Po cut-off voltage for the battery packs you connect.

ESC’s factory default is ON for Li-Po Cut-Off Circuitry

This circuitry lets you safely use 2S or 3S Lithium Polymer battery packs by

cutting off the speed control’s throttle output when a critical safety voltage

is reached (6.25V for 2S and 9.375V for 3S).

The circuitry constantly monitors the pack voltage. When it gets close to

the critical safety voltage it begins interrupting, or “blipping,” the throttle

output as an early warning that the battery’s voltage is getting low and the

throttle output will soon be completely shut off.

When the critical voltage is reached, the throttle output to the motor gets

completely shut down to keep the voltage from dropping further

(Red & Green

LEDs will alternately flash & you still have steering control)

.

Re-charge battery after Smart-Stop circuitry shuts off throttle.

Even though the pack’s voltage will rise

(after a short resting period)

to a level

high enough to run the motor again, this is not good for Li-Po batteries.

Reaching the critical safety voltage too many times can damage the cells.

DO NOT CONTINUE TO RUN VEHICLE AFTER THE LI-PO CUT-OFF

HAS SHUT DOWN THE THROTTLE OUTPUT FOR THE FIRST TIME.

During power-up when the ESC is switched ON, the Amber & Red LEDs will flash

together 2 times for 2S or 3 times for 3S packs to indicate Li-Po Cut-Off is ACTIVE.

With the Li-Po Cut-Off turned ON & using Ni-Cd or Ni-MH cells, the circuitry will shut off the ESC’s

throttle output, due to the different characteristics of these batteries. To deactivate software, see page 6.

LI-PO DETECT & CUT-OFF

The Havoc 3S software lets you reverse a brushless motor’s rotation

direction

(see reverse side of this sheet to select rotation)

. This allows installation

in vehicles with counter-rotating drive trains

(or opposed transmissions)

,

without compromising

performance. Because the ESC will be operating

in its normal forward & reverse modes, features like Smart Braking

continue to operate normally.

MOTOR ROTATION SELECTION

THROTTLE CURVE SELECTION

Throttle Curve Graph

BRUSHLESS MOTORS PINION GEAR

w/ 2S

PINION GEAR

w/ 3S

Ballistic 8.5 (#3608) / SS8.5 Pro (#3408) 15 – 20-tooth 10 – 15-tooth

Ballistic 10.5 (#3610) / SS10.5 Pro (#3410) 17 – 22-tooth 12 – 17-tooth

Ballistic 13.5 (#3613) / SS13.5 Pro (#3413) 20 – 27-tooth 15 – 22-tooth

Ballistic 17.5 (#3617) / SS17.5 Pro (#3417) 25 – 30-tooth 20 – 25-tooth

Ballistic 21.5 (#3621) / SS21.5 Pro (#3421) 28 – 33-tooth 23 – 28-tooth

*At the time of printing, the Traxxas® Slash™ RTR kit included an 18-tooth and a

23-tooth pinion gear.

Slash™ is a registered trademark of Traxxas®.