OPERATION MANUAL

CHARGER 2022 ABLT

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Failure to observe these instructions can cause

personal injury to machine operator or bystanders.

WARNING: Fire or explosion hazard.

NEVER operate this machine in an

explosive atmosphere (grain dust,

flammable liquids or fumes, etc.).

WARNING: Fire or explosion hazard.

NEVER use flammable liquids

(gas, kerosene, solvents, or thinners)

to clean or burnish floor.

WARNING: This product contains a chemical known to the state of California to cause cancer

and birth defects or other reproductive harm.

INTENDED USE

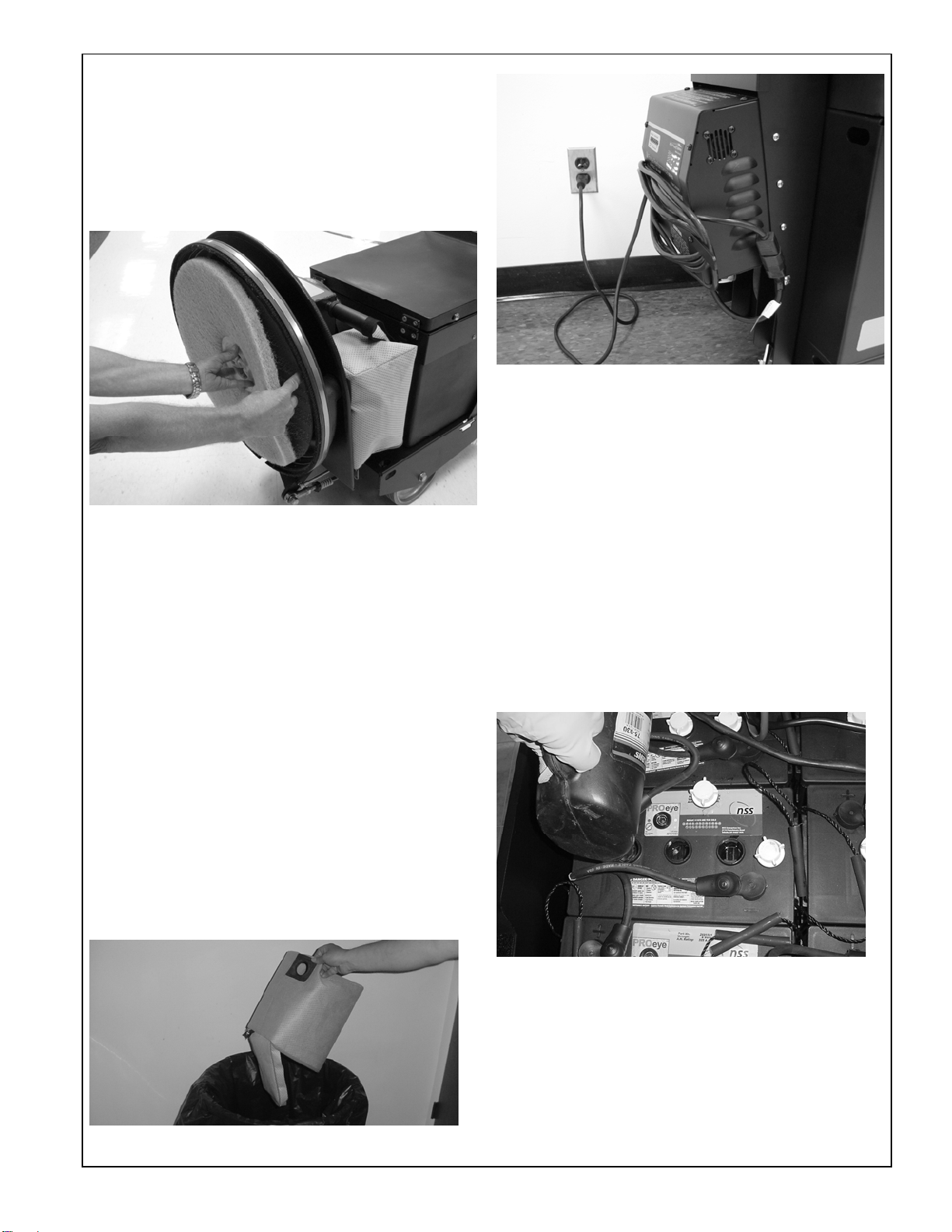

NSS Burnishers are intended for commercial use,

buffing and burnishing floors in an indoor environment.

It is not intended for spray burnishing.

NSS Burnishers are Twister Approved.

NSS does not recommend using these machines for

any other purpose.

FOR SAFETY

•ALWAYS read and understand all instructions before

operating or servicing machine.

•ALWAYS use this machine ONLY as described in

this manual.

•NEVER attempt to operate this machine unless you

have been trained in its operation.

•NEVER allow an untrained person to operate this

machine.

•ALWAYS operate this machine from the rear control

panel, not from the side.

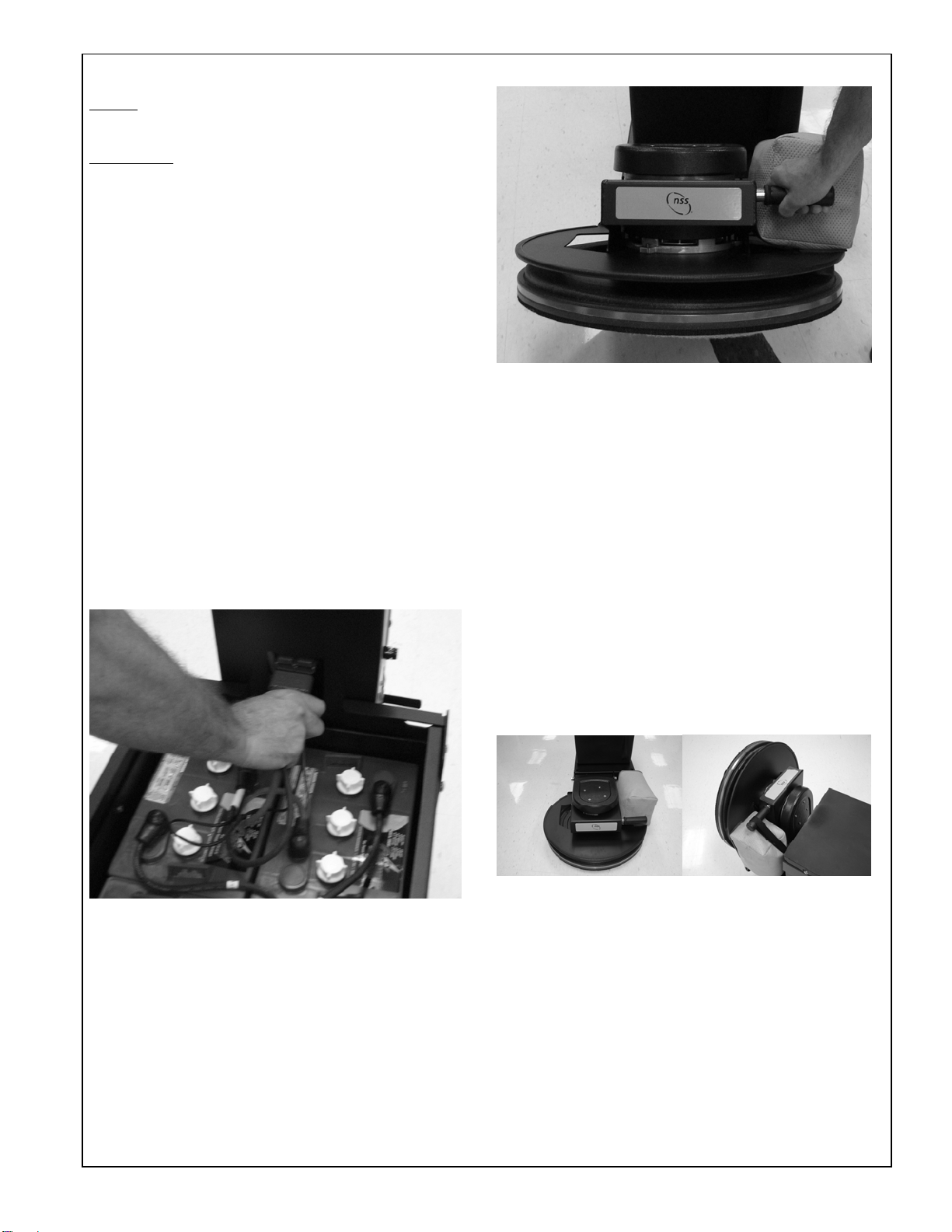

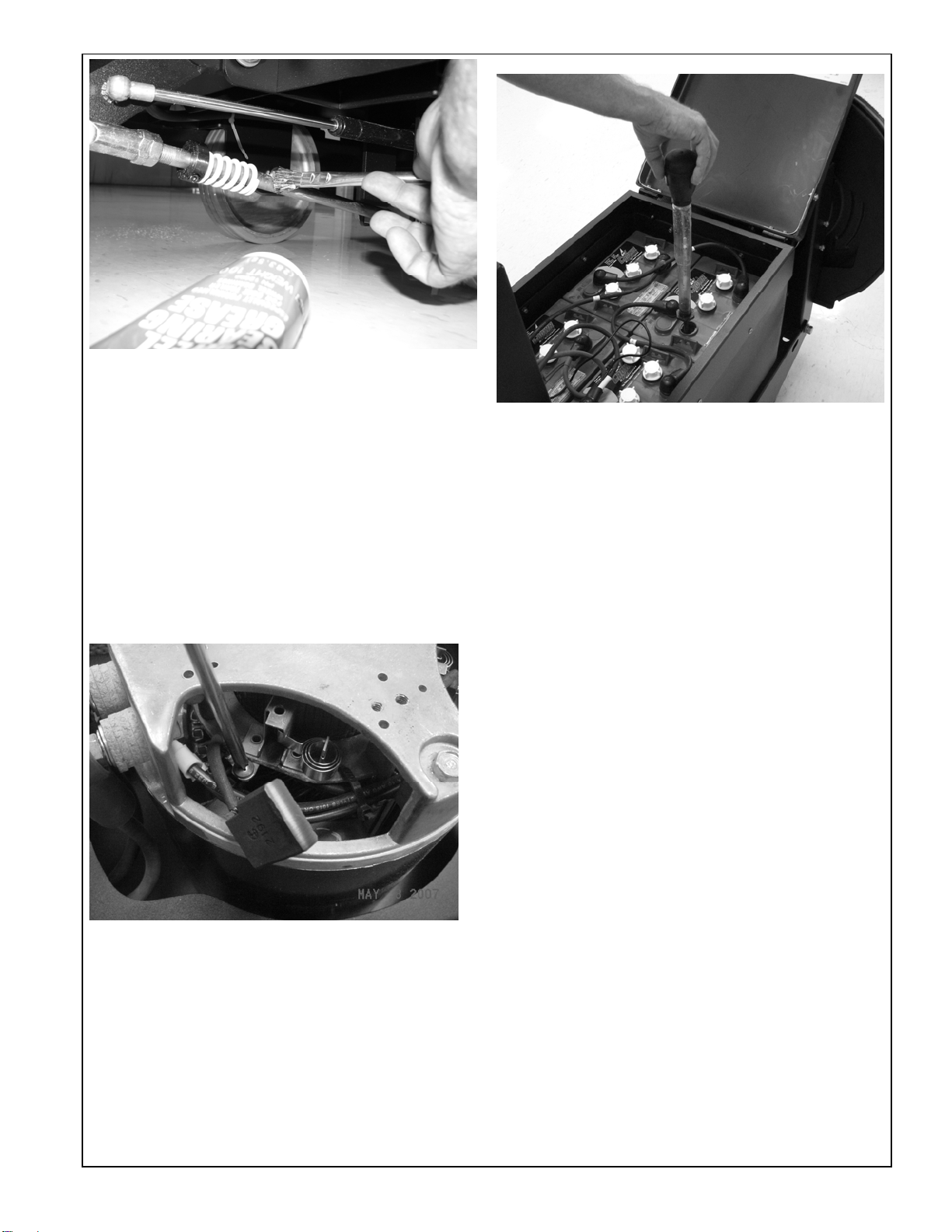

•ALWAYS turn off master switch when attaching or

changing pads.

•NEVER attempt to operate this machine if it is not

working properly or has been damaged in any

manner.

•NEVER disconnect or modify any switches or safety

devices (circuit breaker).

•NEVER drop or insert any object into any machine

opening.

•NEVER operate this machine with any air opening

blocked. Keep all air openings free of dust, lint, hair,

etc.

•NEVER pick up anything that is burning or smoking,

such as cigarettes, matches or hot ashes.

•NEVER allow this machine to be used as a toy. Close

attention is necessary when used by or near children.

•ALWAYS wear clean tennis shoes or “non-slip” shoes.

Leather soled shoes will be extremely slippery.

•ALWAYS keep face, fingers, hair or any other body

part or loose clothing away from any machine opening

or moving part (revolving pad driver).

•ALWAYS be sure that the ramp is secured to the

vehicle before attempting to load / unload.

•ALWAYS use extreme caution when operating the

machine on a ramp or loading / unloading this machine

into or out of a truck / trailer. Use extreme caution if

the ramp is wet, oily, or covered with cleaning

chemicals.

•NEVER stop or turn the machine on a ramp or incline.

•NEVER attempt to climb a grade or operate this

machine on a ramp or incline of more than 20 degrees.

•ALWAYS store this machine indoors in a dry, cool

area.

•NEVER park or store the machine near a dock, on

ramps, near a furnace, boiler, open flame, or other

high heat source.

•NEVER spray this machine with water or any liquids.

•NEVER allow the battery charging plug to get wet or a

short may occur.

•NEVER operate this machine when the battery

charger is plugged in.

•NEVER operate the machine outdoors or allow

machine to freeze.

•NEVER expose the machine to rain, snow, or extreme

temperatures.

•NEVER store any items on the machine.

ALL REPAIR SERVICE MUST BE PERFORMED BY AN NSS AUTHORIZED DISTRIBUTOR /

SERVICE STATION USING ONLY NSS ORIGINAL EQUIPMENT PARTS.

Charger 2022 ABLT 9092026 07-09 Rev C 03-13