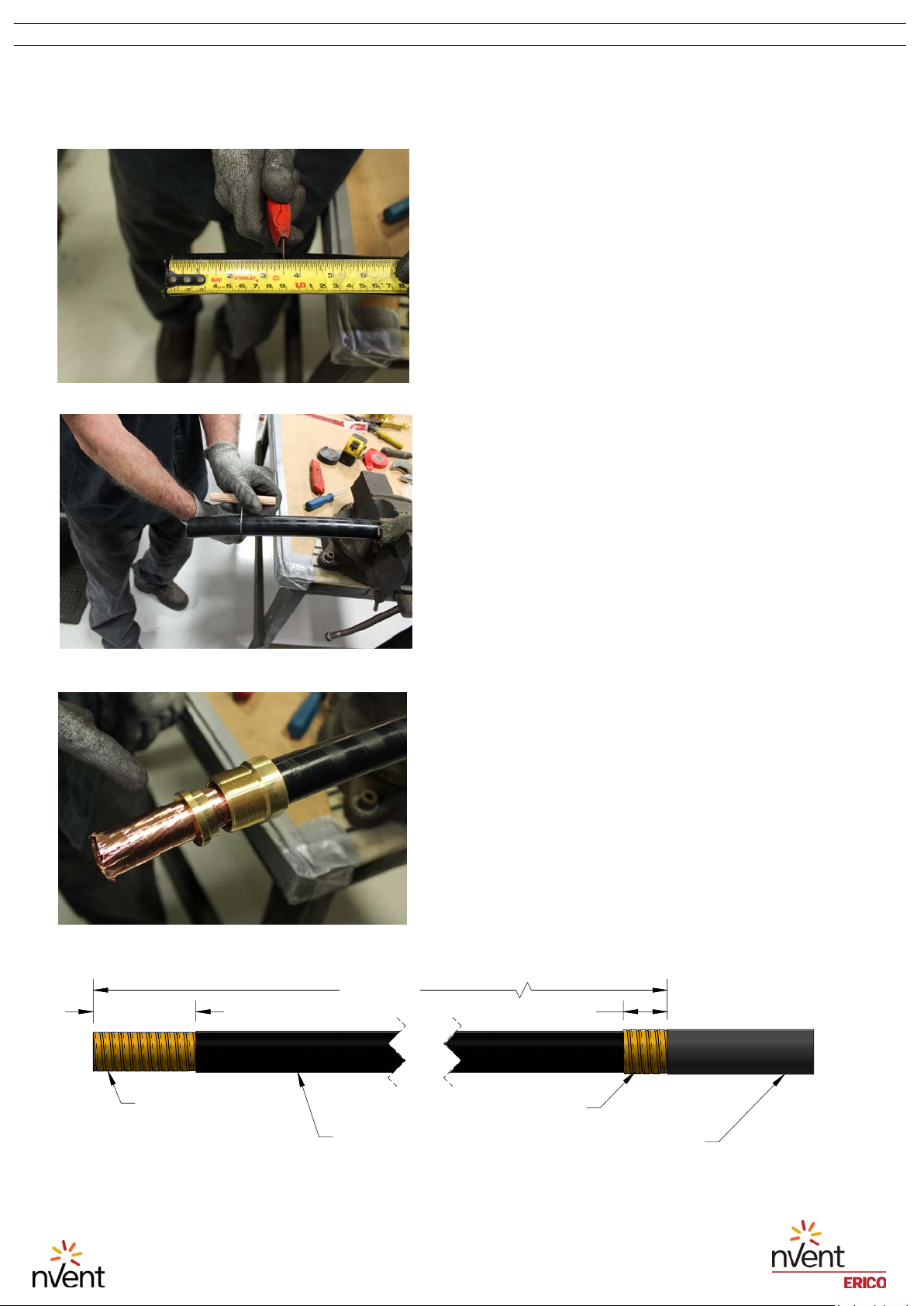

If the instructions are not followed correctly, or if

any of the insulation layers or the copper foil are

incorrectly cut, then the integrity of the upper

termination is affected.

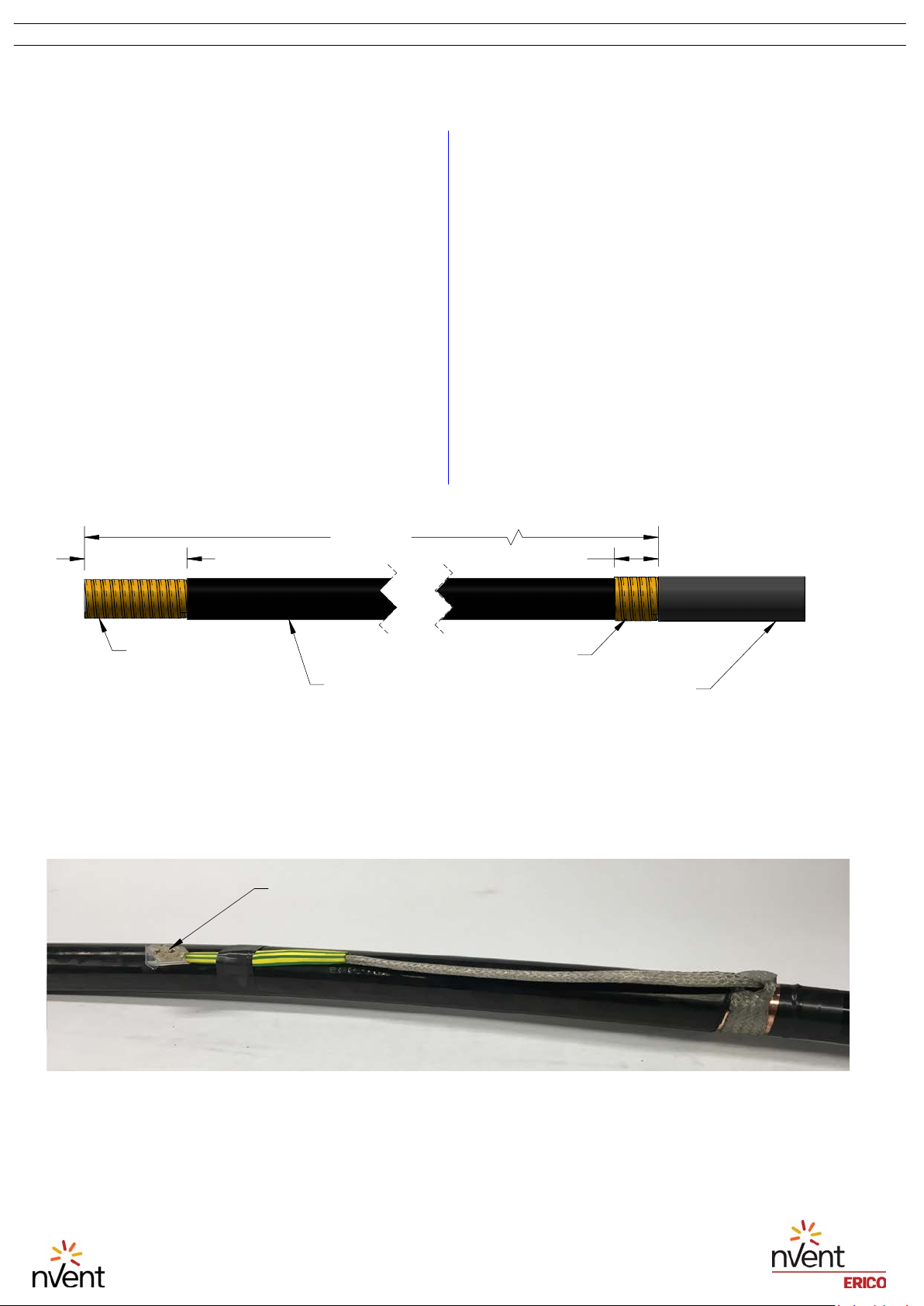

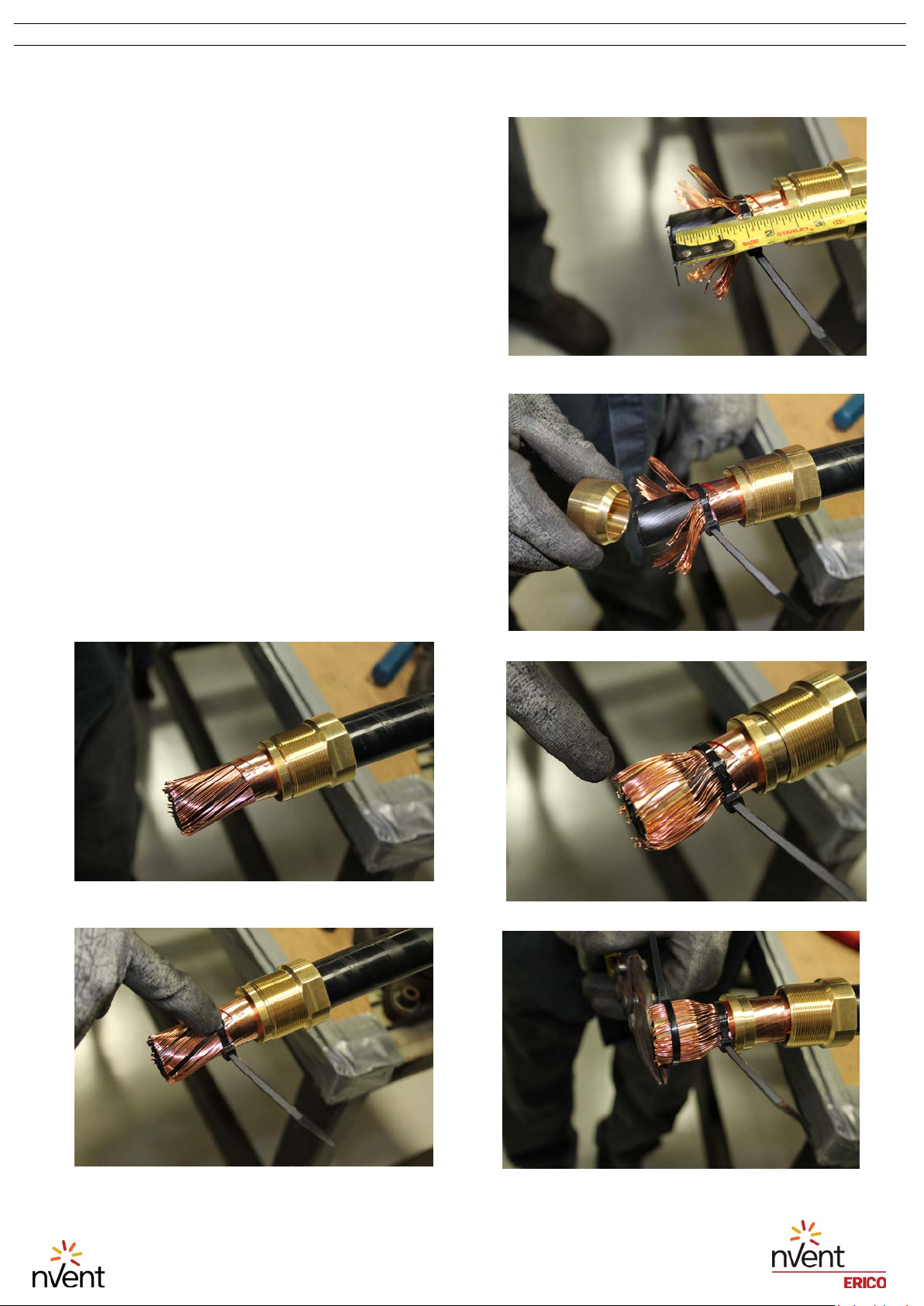

1.

The Ericore cable is marked in 1 meter

increments for its entire length. Start from the

end of the cable with lower number meter

markings. At a distance of 1200 mm (47 1/8

in.), carefully cut a shallow notch into the black

outer insulation no deeper than 1mm (3/64

in.).

2.

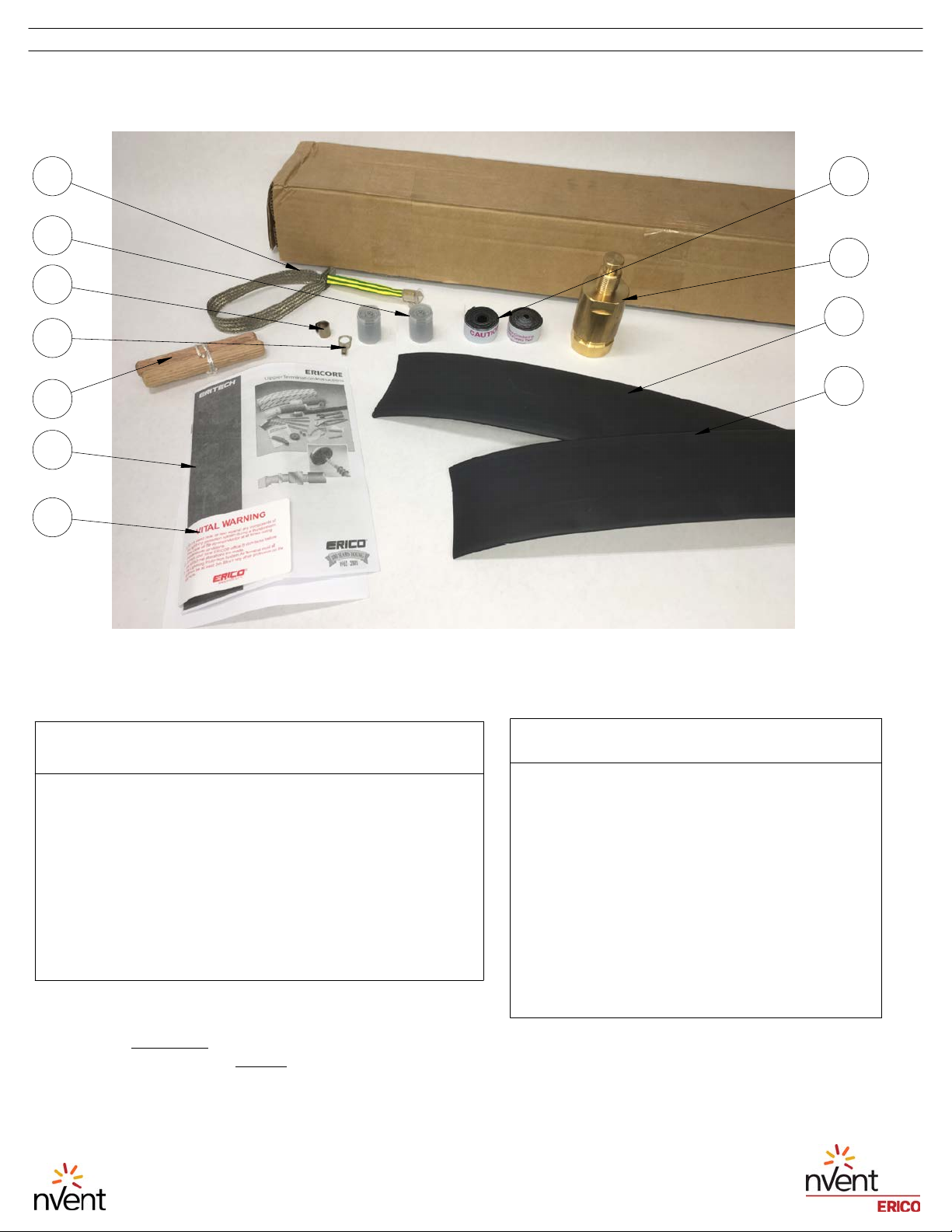

Using the insulation cutting tool (15), cut

around the circumference of the black outer

insulation until the copper screen underneath

is exposed, (see Figure 2). Do NOT use a knife

instead of the provided cutting tool.

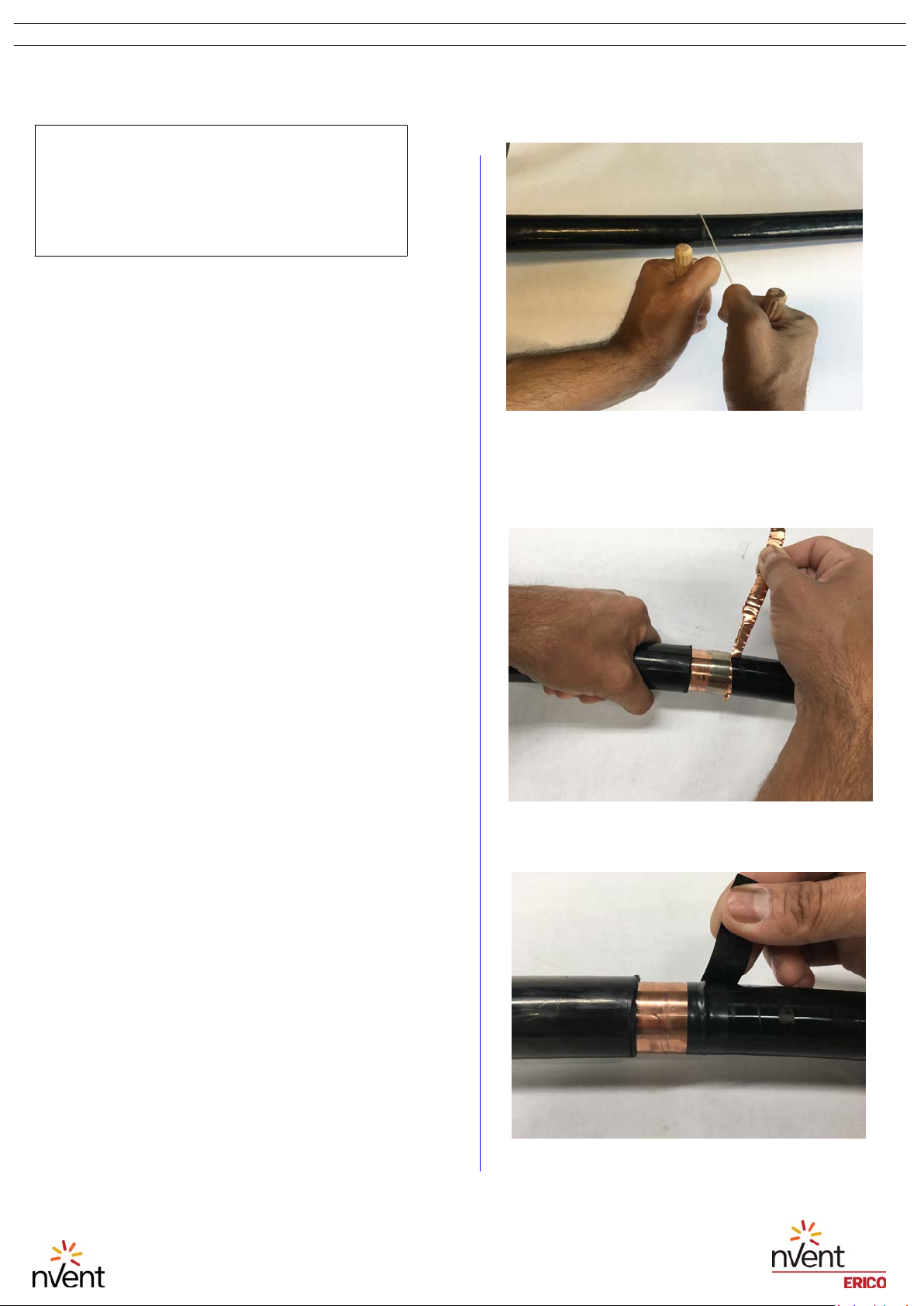

3.

Using a utility knife (1), carefully cut the

outer insulation of the cable to a depth of no

more than 1 mm (3/64 in.), for the full 1200

mm (47 1/8 in.), in the direction of the end of

the cable. Be sure not to cut so deep as to

expose or damage the copper tape underneath.

Starting from the end of the cable, carefully

remove the outer insulation and discard.

4.

Carefully clean up the friction cut, removing

any burrs for a neat finish.

5.

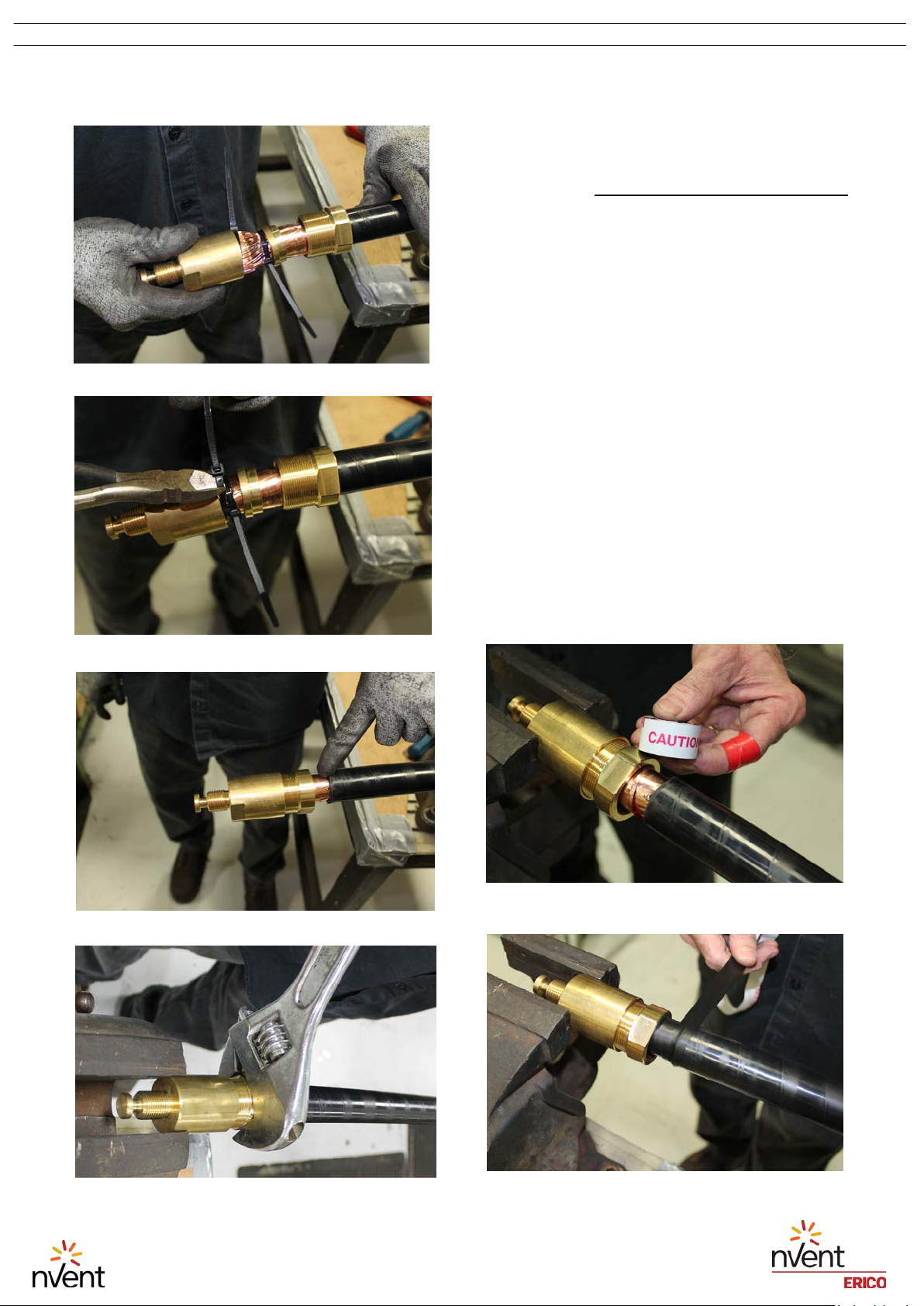

Using a screwdriver (5), fit the roll sping (19)

30 mm (1 1/4 in.) from the end of the outer

insulation over the exposed copper tape.

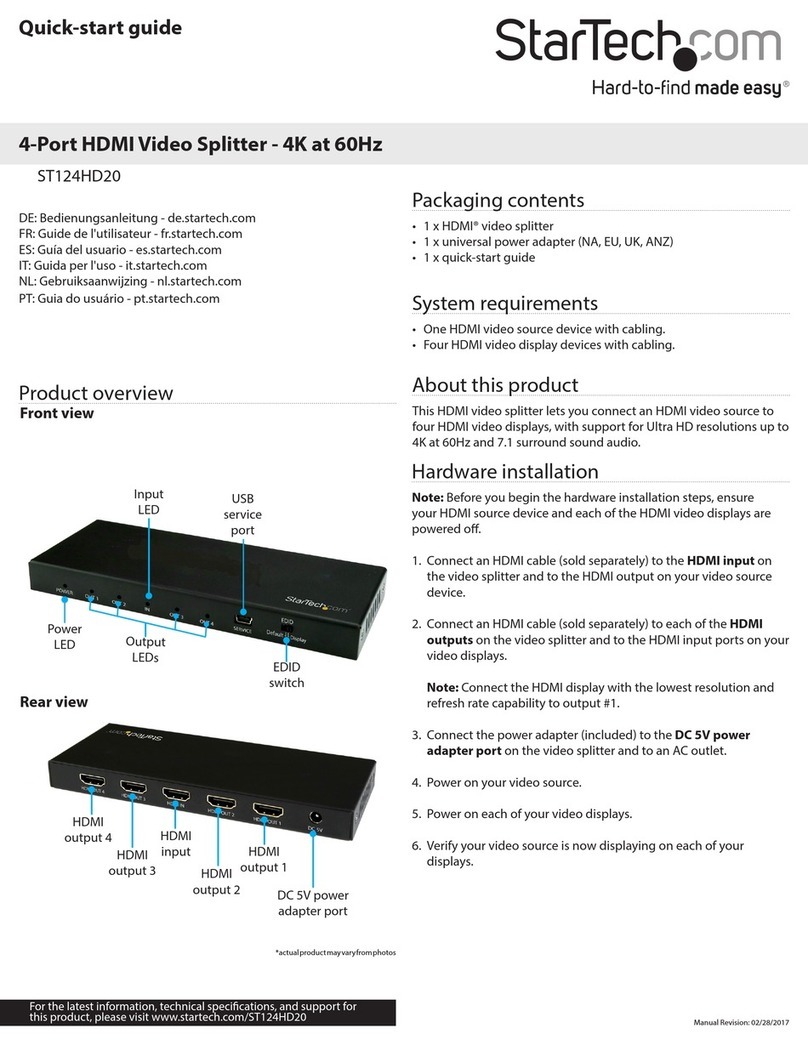

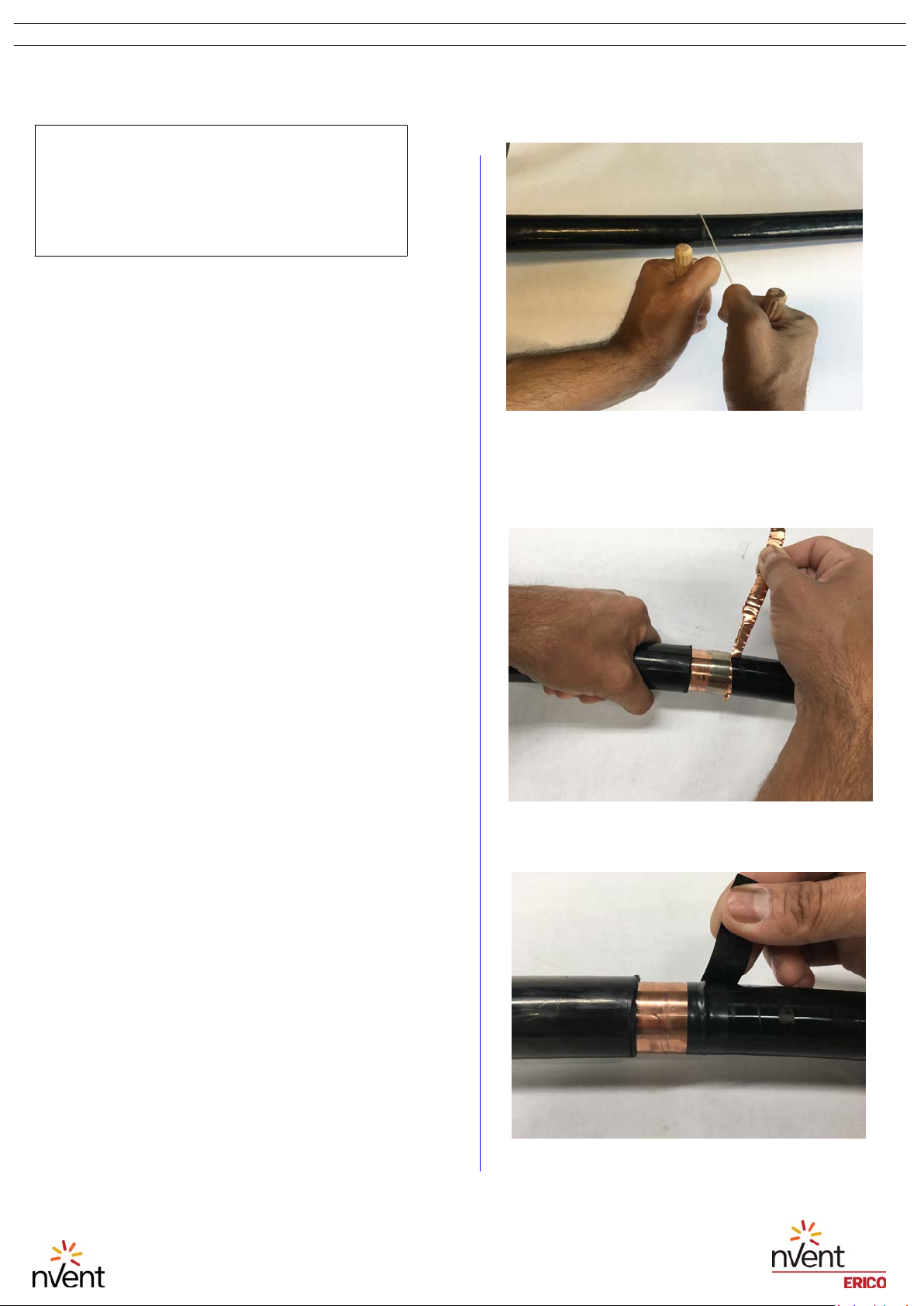

Figure 2:

Use of the insulation cutting

tool to cut the insulation without

damaging the layers beneath

Figure 3:

Using the roll clip to cut and

remove the copper screen

Figure 4:

Placing PVC tape to prevent

further unraveling

Refer to Figure 5 on page 3 for the

following instructions (1 to 8).

The Insulation Cutting Tool uses friction

to cut into the sheath and is less likely to

damage the layers underneath than

using a knife. When the instructions call

for the knife to be used, be sure not to

cut any deeper than instructed.

IP8519_A

2 OF 11

INSTRUCTION SHEET

© 2019 nVent All Rights Reserved

TECHNICAL SUPPORT

www.nVent.com

nVent, nVent CADDY, nVent ERICO Cadweld, nVent ERICO Critec, nVent ERICO, nVent ERIFLEX, and nVent LENTON are owned by nVent or its

global affiliates. All other trademarks are the property of their respective owners. nVent reserves the right to change

specifications without prior notice.