1

Preface

READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

CAUTION

(Risk Group 2): Possibly hazardous optical radiation emitted from this product. Do not stare at operating

lamp. May be harmful to the eye.

WARNINGS

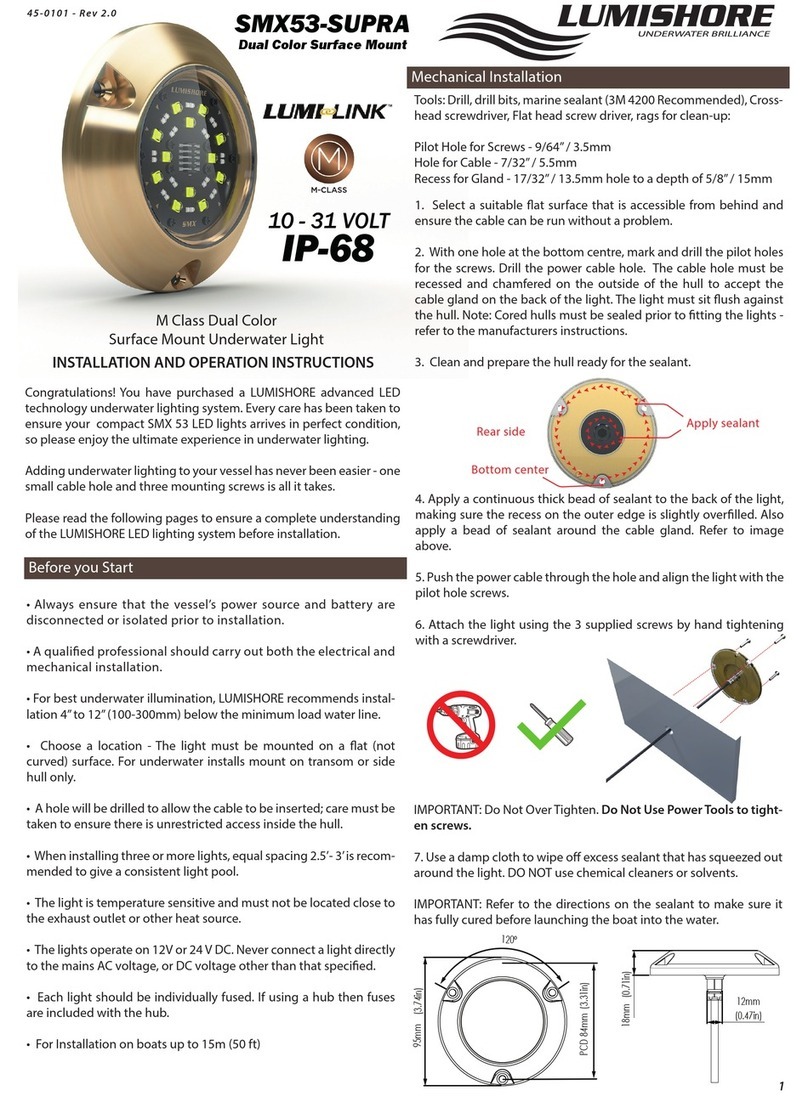

Before installing your OceanLED Light, read and follow all warning notices and instructions which are

included. Failure to follow safety warnings and instructions can result in property damage, severe injury or

even death.

Before installing your OceanLED Light, check local laws for restrictions regarding the use of coloured lights

in your area.

Do not operate lights out of water for a period longer than 5 minutes followed by an OFF period of at least 1

hour. Exceeding this may cause damage to the light unit.

Ensure the bonding point of the light is fitted to the cathodic protection system on the vessel. Check

conductivity between earth bonding point and aluminium bronze front bezel. If mounting the light to metal,

wood, or carbon fibre hull, ensure that suitable measures have been put in place to account for the effects of

galvanic corrosion i.e. use of Delrin sleeve components (Isolation Kit).

Salt is an inherently corrosive material. Metal parts and certain natural and man- made surfaces are

particularly susceptible to corrosion and deterioration when used in and around salt water. Some OceanLED

lights contain combinations of plastic and polymer products which are impervious to saltwater corrosion,

however, screws and fasteners used for the installation must be of a marine grade type stainless steel or

equivalent and monitored annually to ensure the lights remain in service for years to come.

Never connect/disconnect lights with power applied as irreversible damage may occur. Ensure polarity of

power connections is correct. Failure to do this may invalidate warranty.

Ensure front of lights are always fully submerged and not fitted on planning / running surfaces that may

impact on water since this may damage the product. Also ensure the rear of the light is in a dry area and not

subject to a wet environment. Failure to do this may invalidate warranty.

Never Use Solvents! Cleaners, fuel, and other products that may contain strong solvents, such as, but not

limited to, acetone, that attack many plastics greatly reducing their strength and irreversibly damaging the

special lens coatings and cable sheathings.

Never clean lights using a high-pressure jet wash –this will invalidate warranty.

DANGER

RISK OF ELECTRIC SHOCK OR ELECTROCUTION

This underwater light must be installed by a licensed or certified electrician in accordance with all applicable

local codes and ordinances. Improper installation will create an electrical hazard which could result in death

or serious injury to swimmers, installers, or others due to electrical shock, and may also cause damage to

property. Always disconnect the power to the light at the circuit breaker before servicing the light.