Insert the light on to the hull, feeding the cable through first and seat into

place. Press the light hard into the hull and ensure good adhesion.

3. To ensure correct dispersion of light underwater, ensure all Xtremes are

mounted with the correct orientation with text facing upwards. Tip: During/

after fitting process, ensure cable is not under any undue stress.

4. We recommend you only use the mounting screws provided. If alternative

screws are used, do not use counter sunk or non-flat shoulder screws.

Cover the threads with the sealant and screw into the pre-drilled pilot holes.

WARNING: Tighten the screws with a hand tool ONLY!

5. Once you are satisfied that the unit is fully embedded onto the hull, you will

notice that sealant has squeezed out from around the perimeter of the light.

Using a cloth wipe o excess sealant to leave a clean seal. If you do not see

sealant squeeze out from the body, you have not used enough sealant or

tightened the unit enough to the hull. Carefully examine the installation to

make sure the seal you have installed on the unit is fully water-tight. If in

doubt, remove light, re-apply sealant and re-install.

3. Connecting the light fixture

Warning: Always consult a qualified electrician when connecting OceanLED light

fixtures when connecting light units, please note that all OceanLED lights will

operate within a specific voltage range. Connecting lights to your V DC power

source it is recommended to connect the light to the DC power source using a

two pole, screw type terminal block with a minimum voltage rating of 50V and

a current rating of at least 5A. The ends of the cable should be stripped back (if

required) and suitable ferrules fitted. The terminal block should be fixed inside a

waterproof enclosure (IP66 minimum).

It is recommended to connect the light to the DC power source using a two

pole, screw type terminal block with a minimum voltage rating of 50V and a

current rating of at least 5A. The ends of the cable should be stripped back (if

required) and suitable ferrules fitted. The terminal block should be fixed inside a

waterproof enclosure (IP66 minimum).

Tip: Switch and breaker need to be robust enough to support light.

Tip: For complete instructions on V DC connections, please refer to ABYC codes

of practice and other applicable codes and ordinances for V DC connections.

Warning: Never leave the bare cables unprotected. Take care to not leave the

bare wire ends in bilge water before making the waterproof connections. Water

deposits in the connectors and cables will cause corrosion. Over time water

can also work its way into the unit along the inside of the cable due to capillary

action causing the light to fail. This will NOT be covered under warranty.

The colour change version of the X-Series can be used in one of two modes,

either by DC switch mode, or via DMX control mode. For DMX control mode, the

OceanDMX Xtreme Series Controller kit is required – please refer to the manual

included with the kit for connection details. For DC switch mode, connect the

red wire to the +ve supply, and the black, brown & yellow wires to the -ve supply:

1. Depending on the model of lights currently installed you will need to pull

the correct sized power cable from the breaker/fuse panel to the light

locations to supply constant power to the units. It is imperative that the

correct sized tinned boat cable is used.

2. Using waterproof butt splices or IP66 waterproof junction boxes, make

the connections at either end of the system to attach the lights to the vDC

system. If appropriate always use a dielectric grease when making the

connections and make sure any heat shrink used completely encapsulates

the outer wire sheath (the use of glue-lined heat shrink is highly

recommended to ensure water tightness).

NOTE: Corrosion of wire, and/or water ingress into the light unit via the

cable is NOT covered under warranty.

3. If you are not installing a custom fuse panel, it is imperative that the

OceanLED supplied fuse is installed on each power line from each light.

Please consult electrical specification in the online manual to select the

correct fuse dependant on which model of light you have.

Sealant

OceanLED makes every eort to protect our marine and fresh water

environment as well as our natural resources. Please take care to keep

packaging away from and out of the water by ensuring loose packaging

materials are secured and not susceptible to being blown into the water.

Please recycle all packaging materials as the sustainability of our environment

is everyone’s responsibility.

WARNING: Ensure mounting location is flat and check internally for ease of access or

if there is a rib, strut, stringer or other hull

irregularity

that may interfere with the

installation.

WARNING: Never use power tools to secure your lights; hand tighten only.

WARNING: We recommend you use screws provided. If alternative screws are used,

do not use counter sunk or non flat shoulder screws to secure your lights to the hull.

WARNING: All OceanLED in-water products require dry fitting. When installing, be

sure that the light fits the area and secures to the hull using the appropriate hardware

before applying any sealant.

WARNING: Light is for thru-hull mounting only. Cable and connections exposed to

underwater submersion will not be covered by warranty!

WARNING:There are several dierent hull types. Most are either solid GRP or

cored. Be sure you follow the correct procedures for the hull you are preparing

since all require dierent preparation methods. We will cover the most common

type below. If in doubt please contact your local OceanLED representative or the

boat manufacturer for assistance.

WARNING:Please check all components prior to installation. If there is any

damage to connectors, cables, and/or any other component, please notify

OceanLED BEFORE installation. Failure to notify OceanLED of damage in transit

prior to installation will lead to violation of warranty.

WARNING:Light is for mounting directly to a flat surface on the hull, with the

cable passing through a 1/2” (12.5mm) hole in the hull. Do not submerse your

cable in water; cable and connections exposed to underwater submersion will

not be covered by warranty. Mounting the light in any other configuration, other

than those described in this guide, will invalidate its warranty.

1. Preparing a fiberglass hull

Tip: Always wear safety goggles and a dust mask.

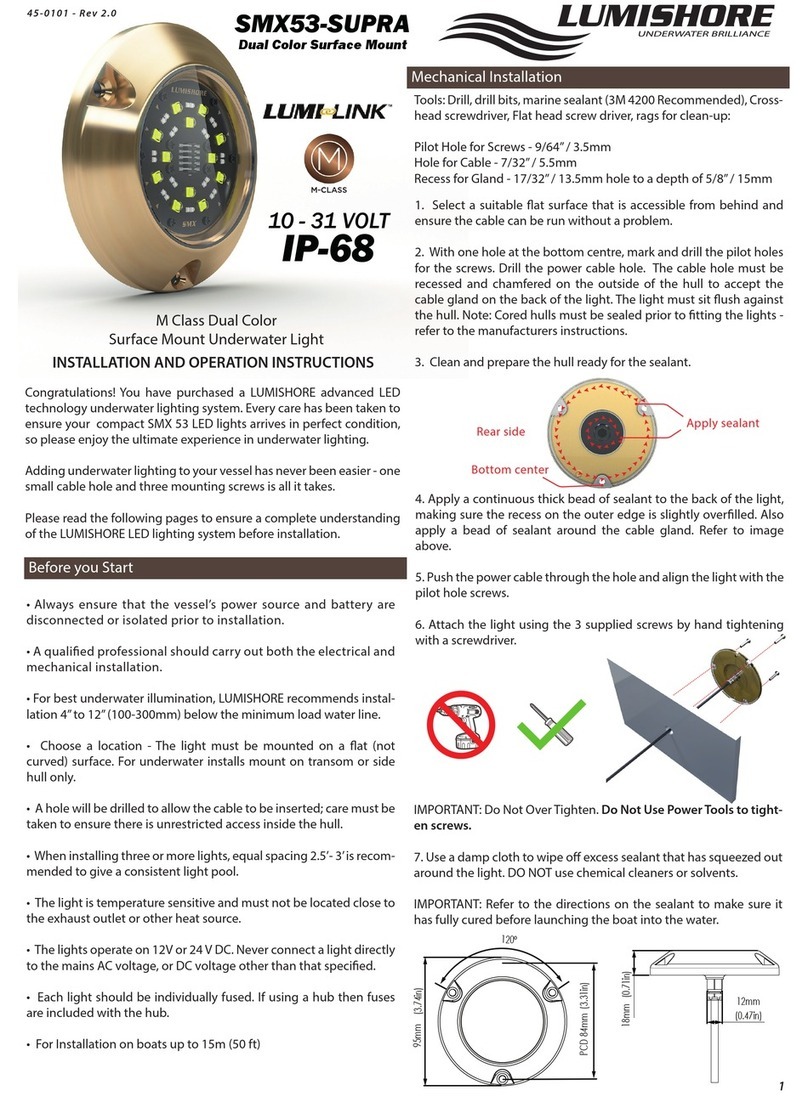

1. Drill a 3mm / 1/8” pilot hole square to mounting surface from inside the hull

if possible. If there is a rib, strut, or other hull irregularity near the selected

mounting location, this will need to be taken into account in the planning

phase and the location adjusted accordingly, or the obstruction safely

removed or modified. If the pilot hole is found to be drilled in the wrong

location, drill a second hole in a better location and repair first pilot hole.

2. Using a suitable drill, make a 1/2” (12.5mm) hole. Ensure the light will fit

flush and will be square to the mounting surface.

3. Sand the area around the hole using a heavy grit sandpaper to remove the

previous bottom paint and to ensure that the sealant will adhere properly

to the hull. If there is any petroleum residue inside the hull, remove it with

acetone before sanding.

4. Place light fixture into position or use mounting template provided. Mark

the screw hole position and pilot drill using correct sized drill bit for

included screws.

5. Always dry fit units before applying any sealant.

2. Installing the light fixture

TIP: Use a suitable marine sealant such as 3M™ Marine Adhesive Sealant Fast

Cure 4200FS. When applying sealant to light fixture, be careful to protect the

lens from any abrasive surface/floor so as not to remove the protective Tritonium

coating.

TIP: If bottom painting your lights ensure lens is free of any paint / residue.

1. Fit desired bezel over light unit.

2. Once hull preparation is complete (see step 1), the light can be inserted into

the hole previously prepared. Apply generous amounts of the sealant you

are using to the back perimeter of the light body. Make sure to generously

coat the cable of the light where it meets the back of the light. There

should be an unbroken bead of sealant around the perimeter of the light

unit.

TIP: It is critical to cover the entire body and circle the mounting screw hole

so that there is a continuous and unbroken bead of sealant.