1

CONTENTS

24

27

27

SPECIFICATIONS

PRODUCT OVERVIEW

SAFETY INSTRUCTIONS

INSTALLATION

LCD DISPLAY DETAILS

TROUBLESHOOTING

MAINTENANCE AND REPAIR

.............................................................................

.................................................................................

....................................................................

......................................................................................4

..............................................................................5

............................................................................6

...........................................................................................7

NOTES BEFORE INSTALLATION

TOOLS REQUIRED

OVERVIEW OF STEPS

STEP ONE - CHECK BOX CONTENTS

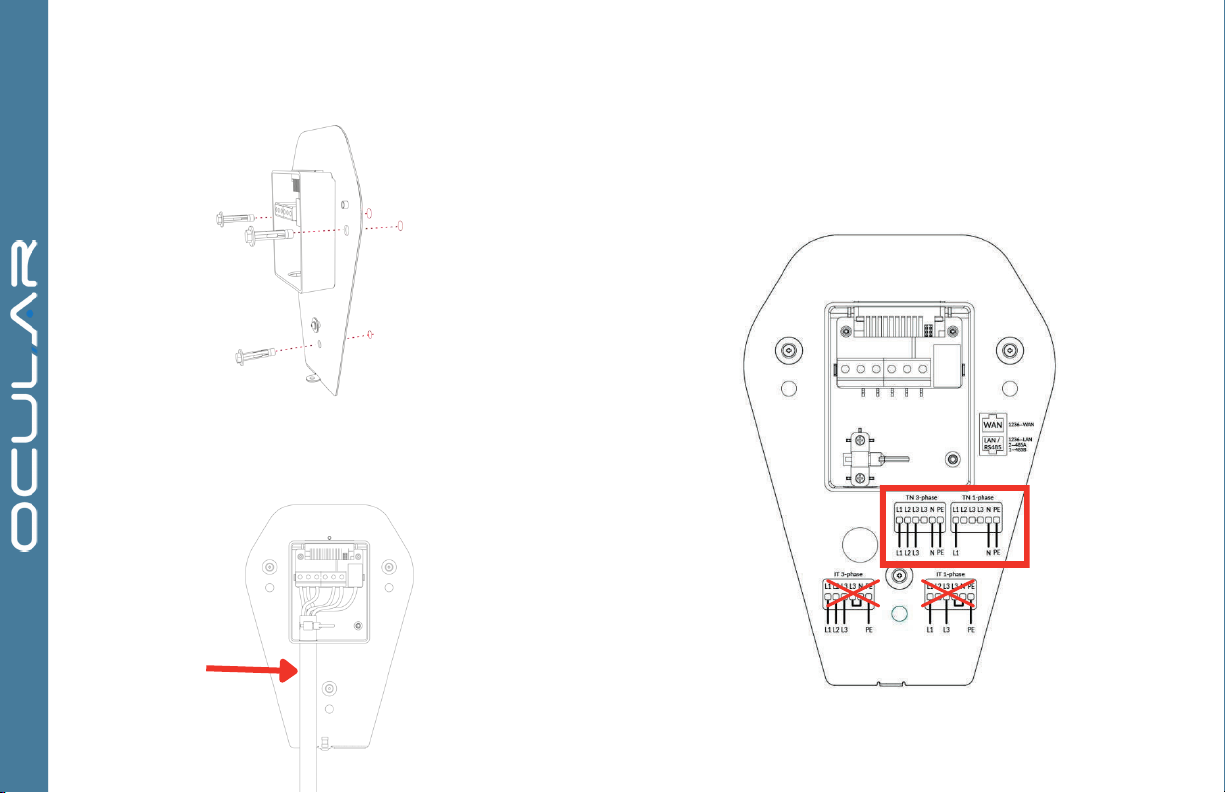

STEP TWO – WALL MOUNTING & WIRING

STEP THREE – INSTALL THE CHARGER

STEP FOUR - INTERNET CONNECTION

WIRING DIAGRAM

STEP FIVE - CT CLAMP INSTALLATION & WIRING

STEP SIX - CT CLAMP SPEC REQIREMENTS

STEP SEVEN - CT CLAMP CONFIGURATION

STEP EIGHT (A) - CT SINGLE PHASE SETUP

STEP EIGHT (B) - CT THREE PHASE SETUP

STEP NINE - CT CLAMP CONFIGURATION (CONTINUED)

STEP TEN - VERIFY THE INSTALLATION

......................................................................................7

............................................................................................................7

...........................................................................................................7

............................................................................7

............................................................8

................................................................9

...........................................................................9

..................................................................................................12

....................................................13

................................................................13

.................................................................15

...................................................................16

..................................................................18

..........................................20

......................................................................22

For information on how to charge your electric vehicle, refer to the documentation

provided with your vehicle.

IMPORTANT !

READ THIS ENTIRE DOCUMENT BEFORE INSTALLING OR USING

THE CHARGER. FAILURE TO DO SO OR TO FOLLOW ANY OF THE

INSTRUCTIONS AND WARNINGS IN THIS DOCUMENT CAN

RESULT IN FIRE, ELECTRICAL SHOCK, SERIOUS INJURY OR DEATH.

THE CHARGER MUST BE INSTALLED BY A QUALIFIED

ELECTRICIAN.

THE ENTIRE INSTALLATION MUST COMPLY WITH THE LATEST

AS 3000 STANDARDS

3

SOLAR INSTRUCTIONS