OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 3

Lubricity (Surface to Surface Drag) Test

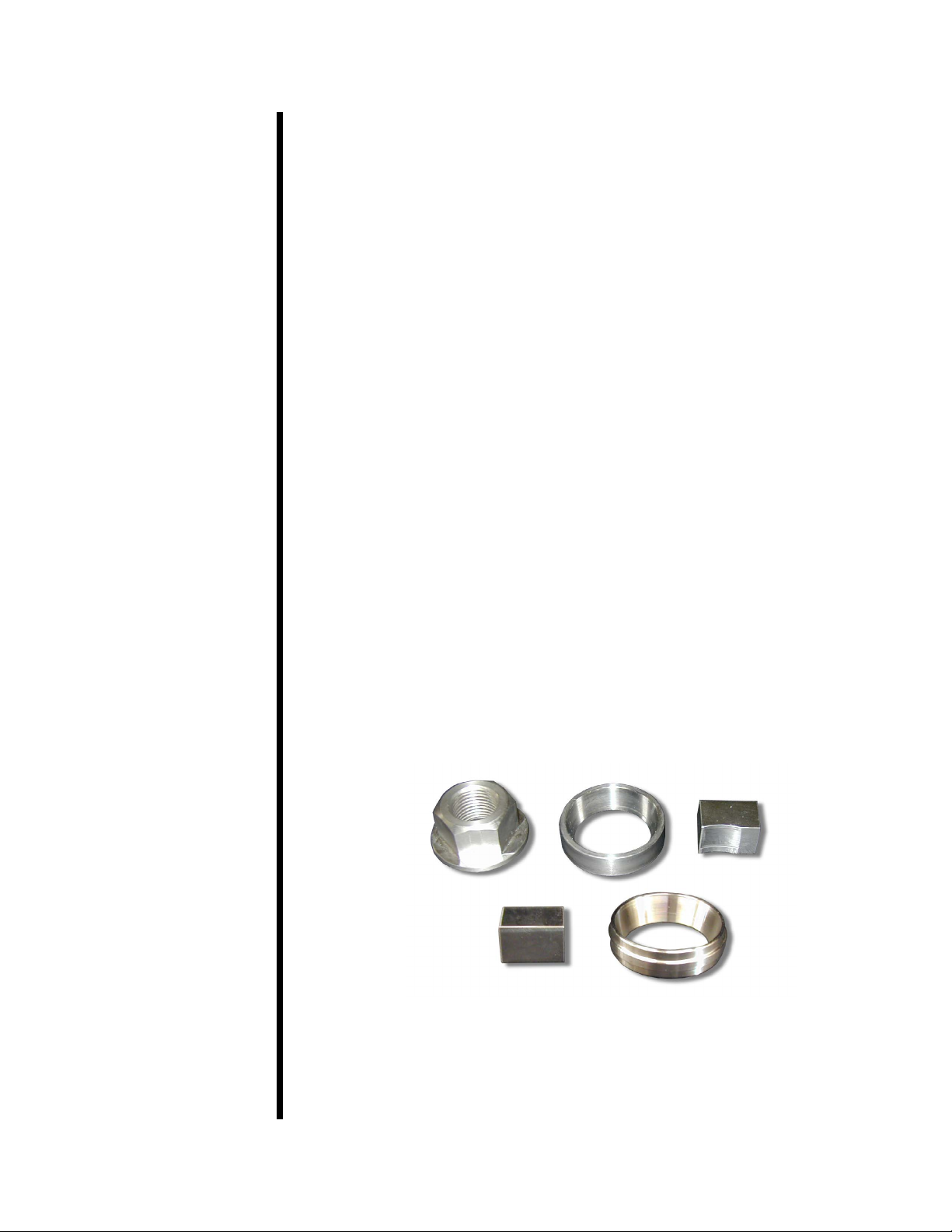

The more common lubricity test measures uid resistance of various

lubricating additives. The standard lubricity coefcient test is run at 60 rpm

with 150 in-lb of force (the equivalent of approximately 600 psi (4,137 kPa)

pressure of the intermediate uid) is applied to two hardened steel surfaces,

a rotating ring and a stationary block.

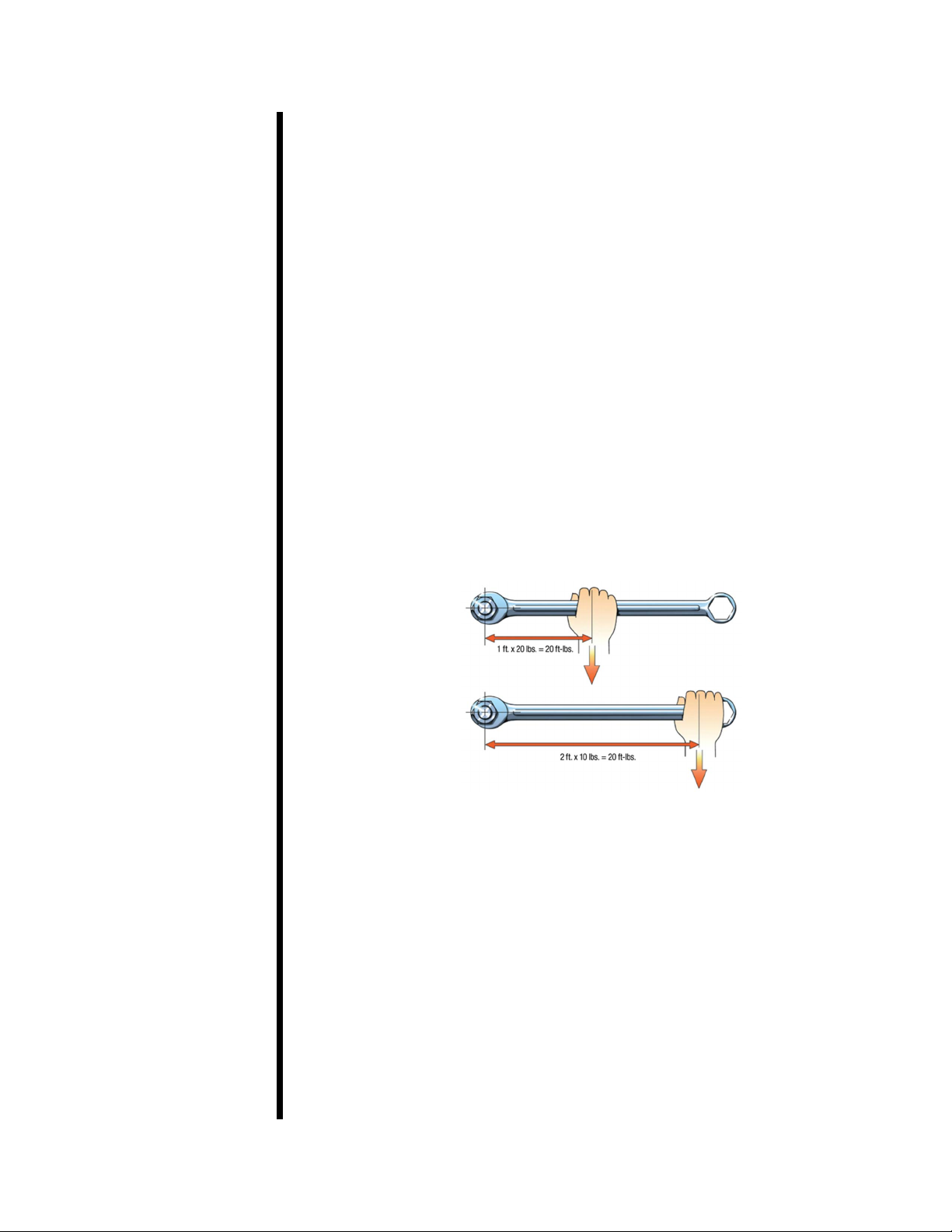

Friction is measured as the coefcient of friction (μ). The coefcient of friction

between two solids is dened as the frictional force of the load or the force

perpendicular to the surfaces. The coefcient of friction is independent of

the apparent areas of contact as long as this area is not so small as to break

through the lm. The force to overcome friction will be the same for a small

area as for a larger area. The force, F, required to slide the block and the ring

surfaces across each other at a given rate is measured by the power required

to turn the test ring shaft at a prescribed rate of revolutions per minute.

The Coefcient of Friction, μ =

EP (Extreme Pressure) Test

This test produces an indication of the lm strength of the uid being tested

by applying a measured force to a torque-sensitive bearing cup with the

torque arm. The EP test is typically run at a high shear rate (1,000 rpm) with

uid pressures ranging from 30,000 to 100,000 psi (206,820 - 689,400 kPa)

between the steel surfaces. Increasing pressure in in-lb of force is applied

until a seizure or pass is obtained.

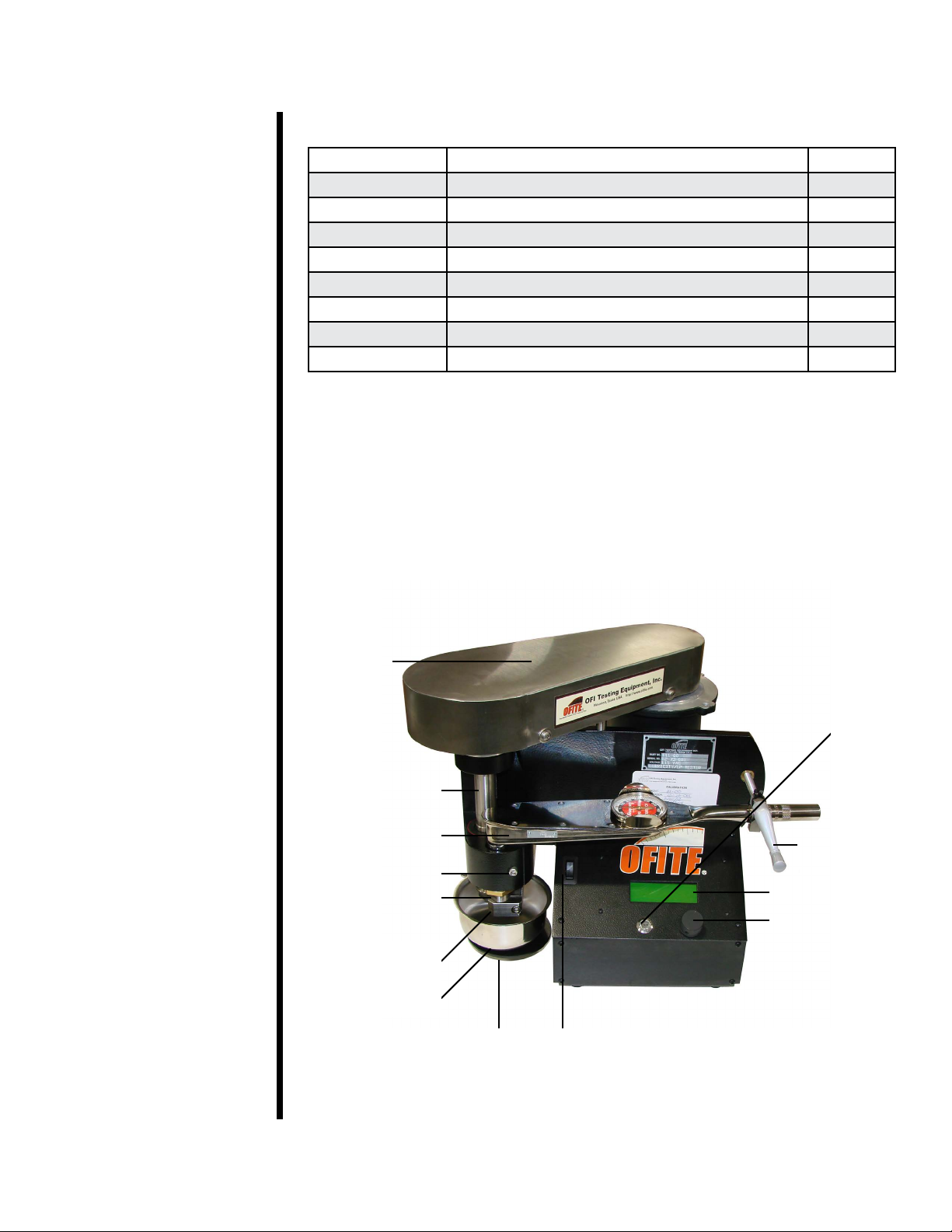

Digital Control

- The digital control panel provides more accurate data than older analog

models.

- The rotational speed (rpm) is automatically maintained as the torque is

increased, resulting in more accurate data collection and is less labor

intensive for the technician.

User-Friendly Interface

- The simple, intuitive interface makes testing quick and easy.

Functions include:

- Pre-Set Speeds: 60, 200, 600, and 1000 rpm

- Manual Speed Control

- Zeroing Torque and Time

- Maximum Speed: 1,000 rpm

- Maximum Torque: 600 in-lb

- Belt-Driven Motor: ½ HP, 90 Volt DC, 5.5 Amps

- Size: 19" × 15" × 14" (48.3 × 38.1 × 35.6 cm)

- Weight: 56 lb (25.4 kg)

Description

Meter Reading

Load or Force

Features