OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 2

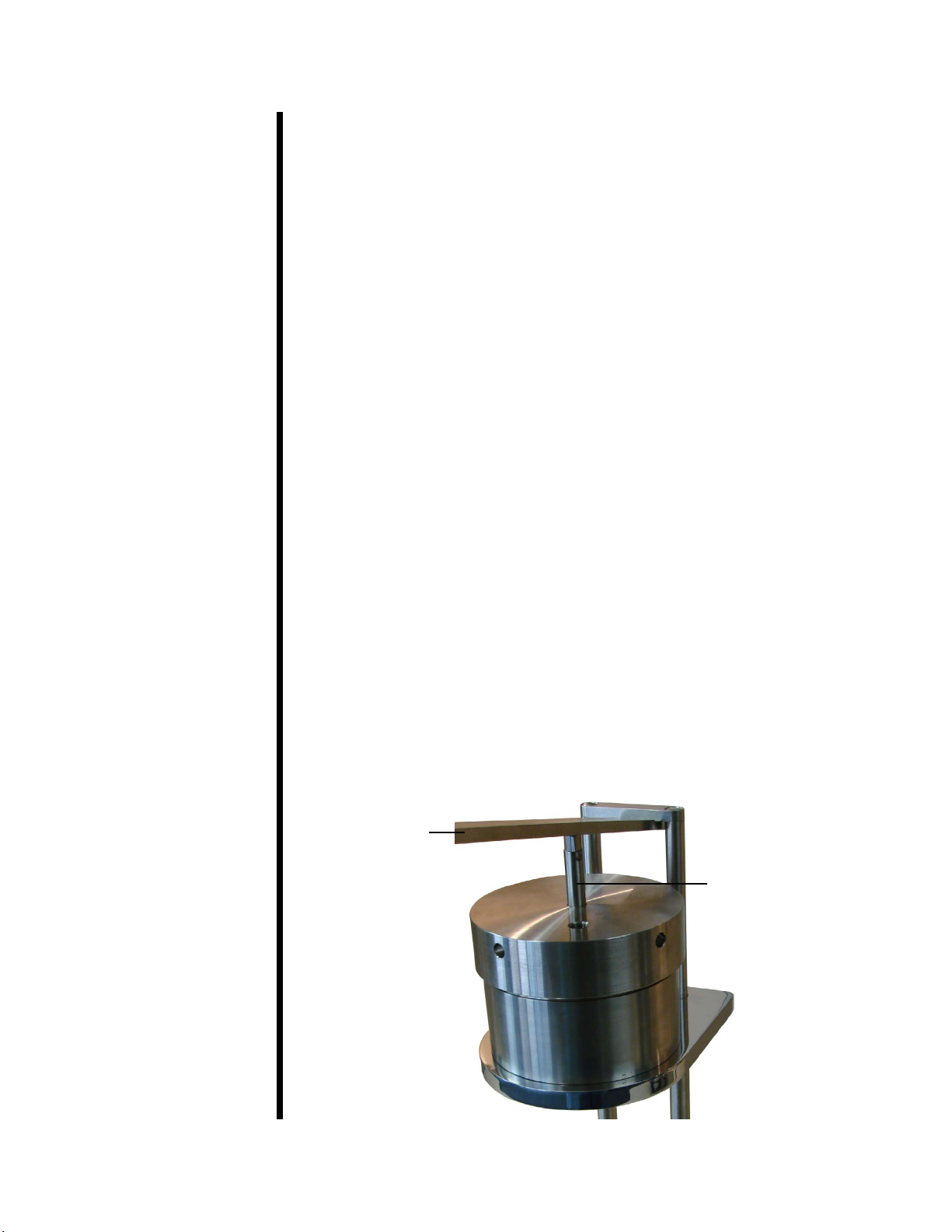

The OFITE Dierential Sticking Tester measures the “Stuck Pipe Tendency

Coecient” of drilling uids, and also determines how eective lubricants or

treatments might be with any given drilling uid. This coecient takes into ac-

count both the friction, or “stickiness”, of the lter cake, as well as the amount

of cake building that must occur in order to freeze or stick the pipe in the hole.

The coecient is determined by running a Timed Filtration test. By measuring

the area of cake building during a test, the “Bulk Sticking Coecient” is ob-

tained and read directly at the conclusion of the test. How likely a given uid

will be to produce a stuck pipe situation and how eective a given treatment

may be, can be immediately determined on-site.

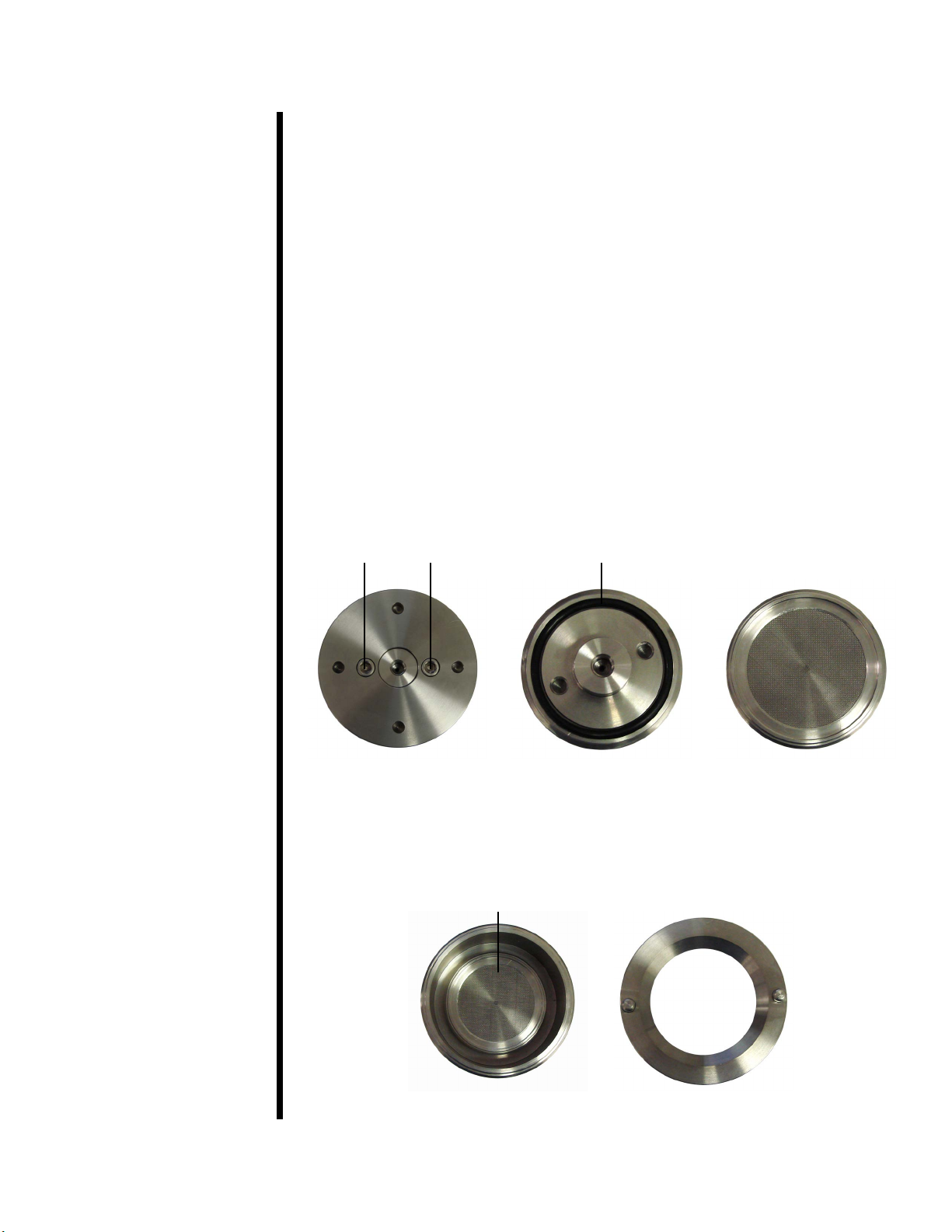

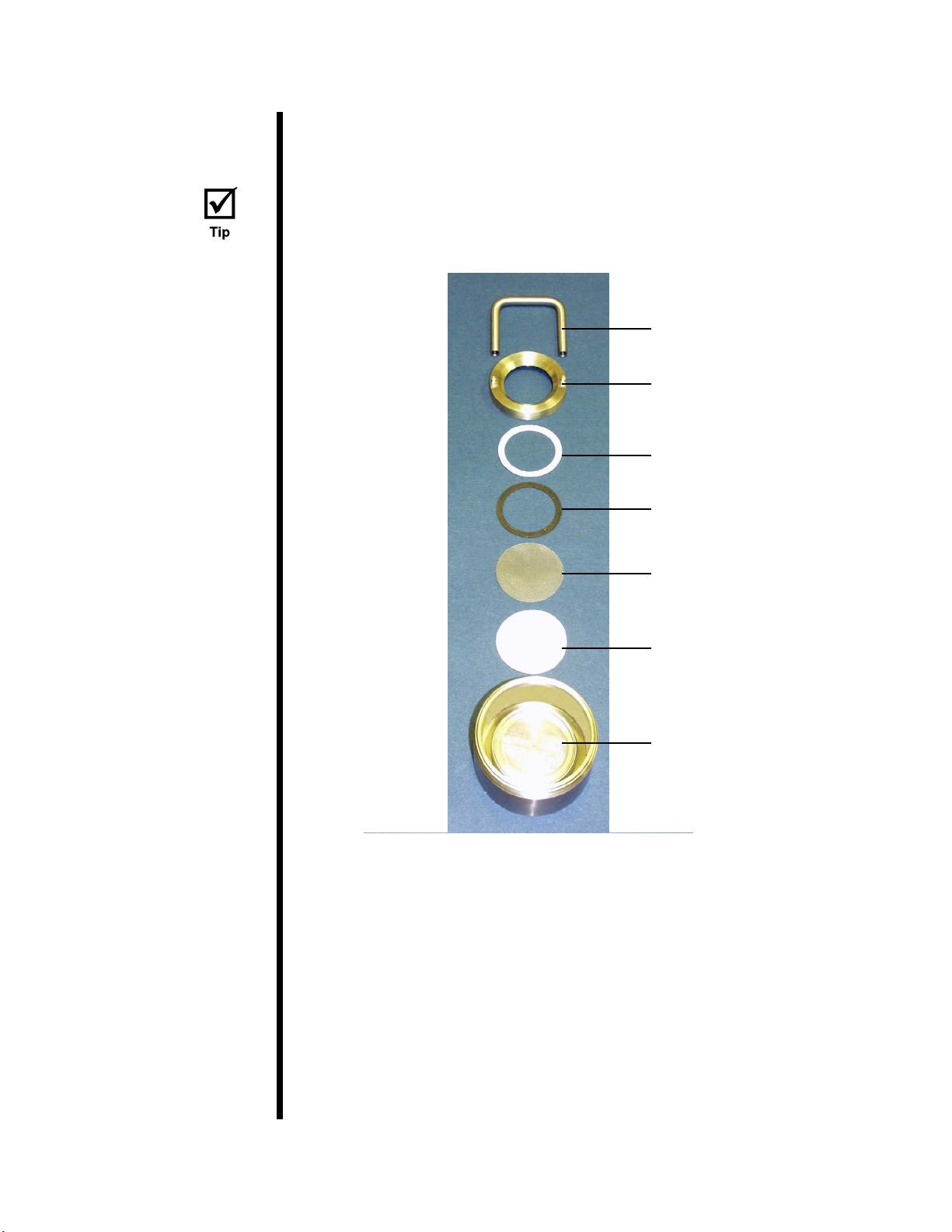

The unit is normally pressurized by a CO2 pressuring assembly, but any

nitrogen source will also work. If nitrogen is used, the tester apparatus must

be tted with a suitable nitrogen regulator, gauges, valves, and high-pressure

hoses. The standard test uses 477.5 PSI (3,291 kPa) applied to a 200-mL

stainless steel vessel. The unit includes both a at-faced plate and a plate of

12½" (31.75 cm) spherical radius, which simulates the pipe inside the casing

or collars in the borehole. For samples that adhere more to the plate than to

the lter paper, stainless steel micro-corrugation disks are provided. For con-

venience a stainless steel carrying case is available as an optional item.

Intro

Description