4

TABLE OF CONTENTS

DESCRIPTION .................................................................................................5

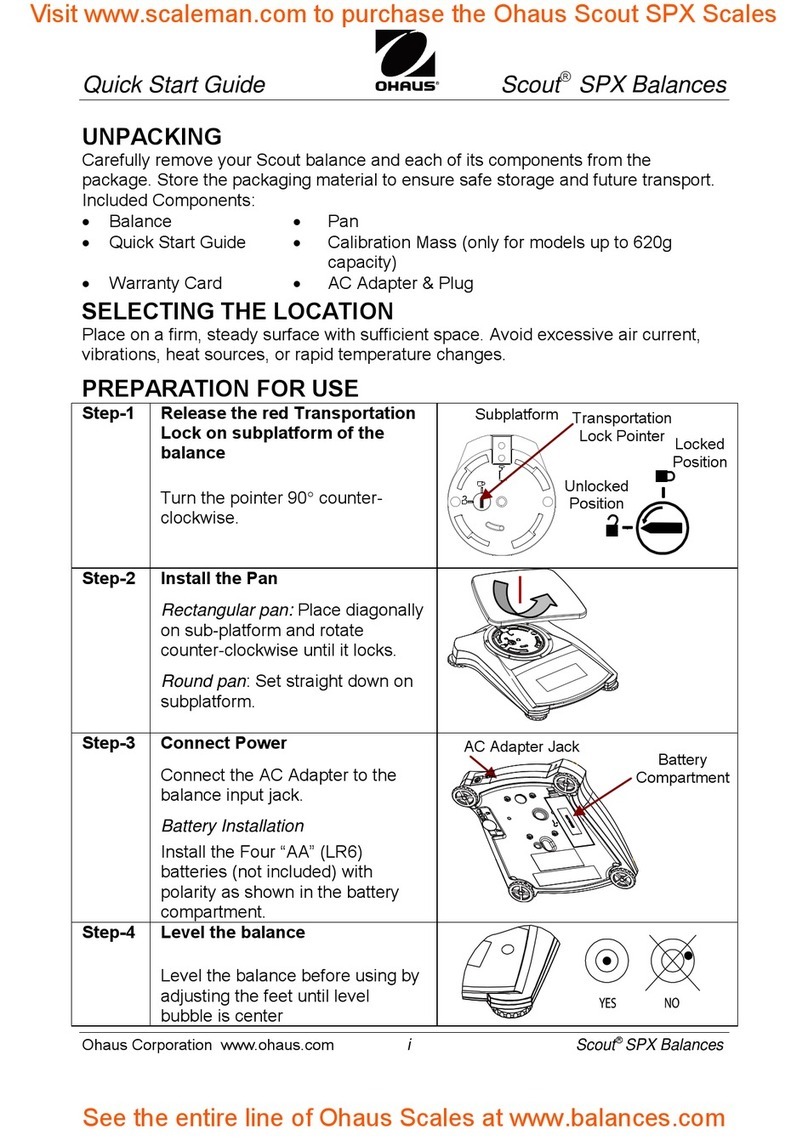

UNPACKING.....................................................................................................5

INSTALLATION .................................................................................................5

Setting Up and Leveling the Balance ................................................5

Pan Installation ..................................................................................5

Connecting Power..............................................................................6

Weigh Below Hook ............................................................................6

Security Bracket .................................................................................6

TURNING THE BALANCE ON .........................................................................6

TURNINGTHE BALANCE OFF ........................................................................6

WEIGHING ........................................................................................................6

TARING ............................................................................................................7

MENU DESCRIPTION......................................................................................7

ACTIVATING UNITS..........................................................................................7

PRINT MENU....................................................................................................8

SETTING PRINT MENU FUNCTIONS .............................................................8

Entering the Print Menu .....................................................................8

Setting Baud Rate ..............................................................................9

Setting Parity ......................................................................................9

Setting Data........................................................................................9

Setting Stop Bit...................................................................................9

Setting Print Modes ............................................................................9

CALIBRATION ............................................................................................... 10

Calibration Masses ......................................................................... 10

Span Calibration ............................................................................. 10

Linearity Calibration........................................................................ 11

PRINTING ...................................................................................................... 11

RS232 INTERFACE....................................................................................... 11

Hardware ........................................................................................ 11

RS232 Commands ......................................................................... 12

Output Formats................................................................................ 12

CARE AND MAINTENANCE ......................................................................... 13

TROUBLESHOOTING ................................................................................... 13

Error Codes ..................................................................................... 13

ACCESSORIES ............................................................................................. 14

SPECIFICATIONS.......................................................................................... 14

Admissible Ambient Conditions...................................................... 14

WARRANTY................................................................................................... 15