44983601TH Rev.1 vi /

Oki Data CONFIDENTIAL Contents

3.3.25 Lever In Sensor / Lever WR Sensor / /Photo Interrupter.........................................................3-32

3.3.26 Paper feeding roller (Roller-Pick-Up,Roller-Feed-NOW,Roller-Assy-MPT).............................3-33

3.3.27 Frame-Assy-Retard , Spring-Retard........................................................................................3-35

3.4 Lubricating points............................................................................................................................3-36

4. ADJUSTMENT..............................................................................................................4-1

4.1 Category and function of maintenance mode ...................................................................................4-1

4.1.1 User maintenance mode (Administrator Menu) .......................................................................4-1

4.1.2 System maintenance mode (System maintenance menu)........................................................4-6

4.1.3 Self-diagnostic Mode...............................................................................................................4-11

4.1.4 Energy conservation mode setting..........................................................................................4-26

4.1.5 EEPROM Initialization.............................................................................................................4-27

4.2 Adjustment at part replacement......................................................................................................4-28

4.2.1 EEPROM data upload / download method .............................................................................4-28

5. Periodic Maintenance...................................................................................................5-1

5.1 Periodic Replacement Parts..............................................................................................................5-1

5.2 Cleaning............................................................................................................................................5-1

5.3 Cleaning of LED lens array ...............................................................................................................5-1

5.4 Cleaning the Feed rollers and the Retard roller ................................................................................5-2

6. Procedures for Repairing..............................................................................................6-1

6.1 Troubleshooting.................................................................................................................................6-1

6.2 Points to be checked before modifying printing problems.................................................................6-1

6.3 Points to be checked when the printing problems are modified........................................................6-1

6.4 Preparation for Troubleshooting.........................................................................................................6-1

6.5 Troubleshooting Flow ........................................................................................................................6-2

6.5.1 LCD Status Message/ Trouble Table .........................................................................................6-2

6.5.2 LCD Message Troubleshooting...............................................................................................6-10

6.5.3 Print Troubleshooting...............................................................................................................6-18

7. Connection Diagram.....................................................................................................7-1

7.1 Connection diagram..........................................................................................................................7-1

7.2 Board Layout.....................................................................................................................................7-2

7.3 Resistance value.............................................................................................................................7-16

Appendix A Centronics Parallel Interface.........................................................Appendix A-1

Appendix B USB Interface................................................................................Appendix B-1

Appendix C Maintenance Manual for Second Tray unit................................... Appendix C-1

1 Overview .............................................................................................................................Appendix C-1

1.1 Function ........................................................................................................................Appendix C-1

1.2 Exterior and Parts Name...............................................................................................Appendix C-1

2. Description for Operation of Second Tray unit.....................................................................Appendix C-2

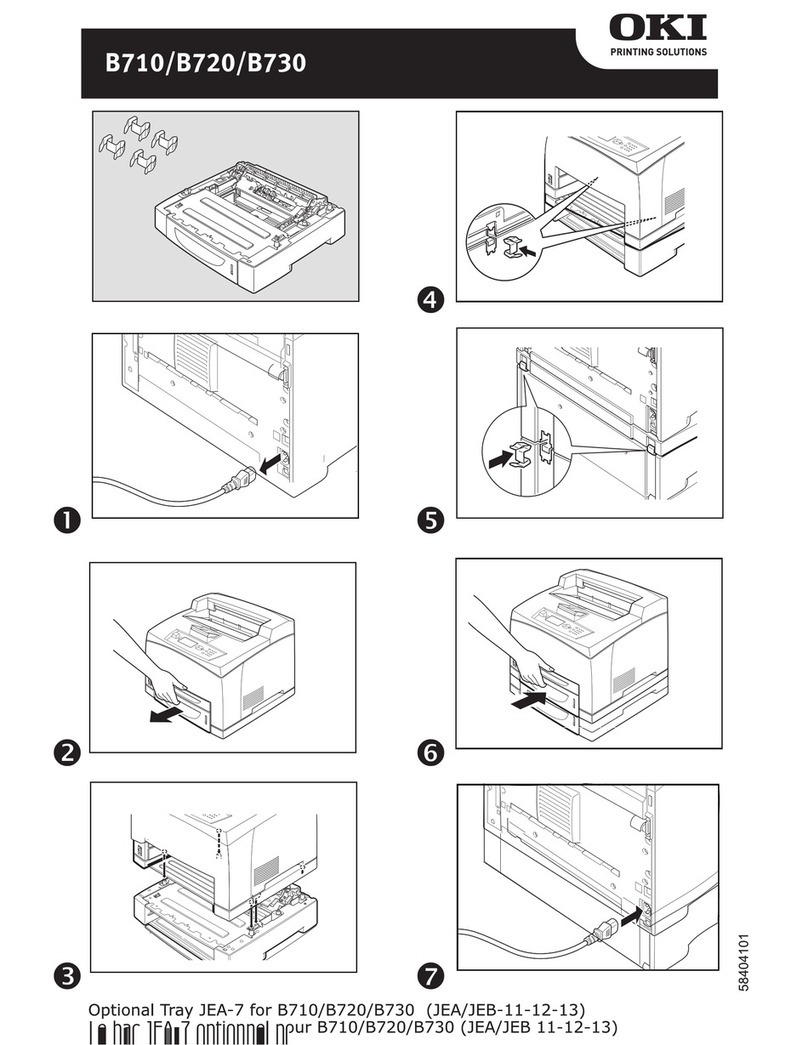

3. Part Replacement................................................................................................................Appendix C-3

3.1 Precautions on replacing parts......................................................................................Appendix C-3

3.2 Arrangement of Parts....................................................................................................Appendix C-4

3.3 How to Replace Parts....................................................................................................Appendix C-5

3.3.1 Roller-Pick-Up, Roller-Feed-Now...........................................................................Appendix C-6