41388601TH Rev.25 /

3.3.16 Registration roller Assy (B)............................................................................... 66

3.3.17 Registration clutch, Registration motor Assy.................................................... 67

3.3.18 Cooling fan ....................................................................................................... 68

3.3.19 Color registration sensor Assy.......................................................................... 69

3.3.20 Duplex guide Assy............................................................................................ 70

3.3.21 Electrical chassis/ Electrical chassis cooling fan.............................................. 71

3.3.22 Printer engine controller PWB .......................................................................... 72

3.3.23 Printer unit chassis ........................................................................................... 73

3.3.24 Entrance cassette sensor actuator................................................................... 74

3.3.25 Entrance sensor PWB ...................................................................................... 75

3.3.26 Entrance MT sensor actuator and Entrance belt sensor actuator .................... 76

3.3.27 Main motor fan/ Fuser eject roller..................................................................... 77

3.3.28 Eject sensor Assy ............................................................................................. 78

3.3.29 Fuser latching handle (L).................................................................................. 79

3.3.30 Belt motor Assy ................................................................................................ 80

3.3.31 Fuser latching handle (R) ................................................................................. 81

3.3.32 Main motor Assy............................................................................................... 82

3.3.33 Contact Assy/ Side plate Assy.......................................................................... 83

3.3.34 Low voltage power supply ................................................................................ 84

3.3.35 High voltage power supply ............................................................................... 85

3.3.36 Main feed Assy ................................................................................................. 86

3.3.37 Fuser unit.......................................................................................................... 87

3.3.38 Belt unit............................................................................................................. 88

3.3.39 Duplex unit........................................................................................................ 89

3.3.40 CU Assy............................................................................................................ 90

4. Adjustment ....................................................................................................92

4.1 Maintenance Menu and Its Functions ............................................................................ 92

4.2 Short Plug Settings ........................................................................................................ 93

4.3 Printing Singly Using Controller-Equipped Printer ......................................................... 93

4.4 Adjustment after Part Replacement ............................................................................... 94

4.5 Color Balance Adjustment ............................................................................................. 95

4.6 EEPROM Replacement after CRM Board and K73 Board Replacement ...................... 97

5. Regular Maintenance ....................................................................................98

5.1 Parts to be Replaced Regularly ..................................................................................... 98

5.2 Cleaning......................................................................................................................... 98

5.3 Cleaning of LED Lens Array .......................................................................................... 98

5.4 Cleaning of Pick-up Roller ............................................................................................. 98

6. TROUBLESHOOTING PROCEDURES ......................................................... 99

6.1 Tips for Troubleshooting ................................................................................................ 99

6.2 Check Points before Correcting Image Problems.......................................................... 99

6.3 Tips for Correcting Image Problems .............................................................................. 99

6.4 Preparation for Troubleshooting .................................................................................. 100

6.5 Troubleshooting Flow................................................................................................... 100

6.5.1 LCD Message List .......................................................................................... 101

6.5.2 LCD message troubleshooting ....................................................................... 106

6.5.3 Image troubleshooting.................................................................................... 117

7. WIRING DIAGRAM...................................................................................... 129

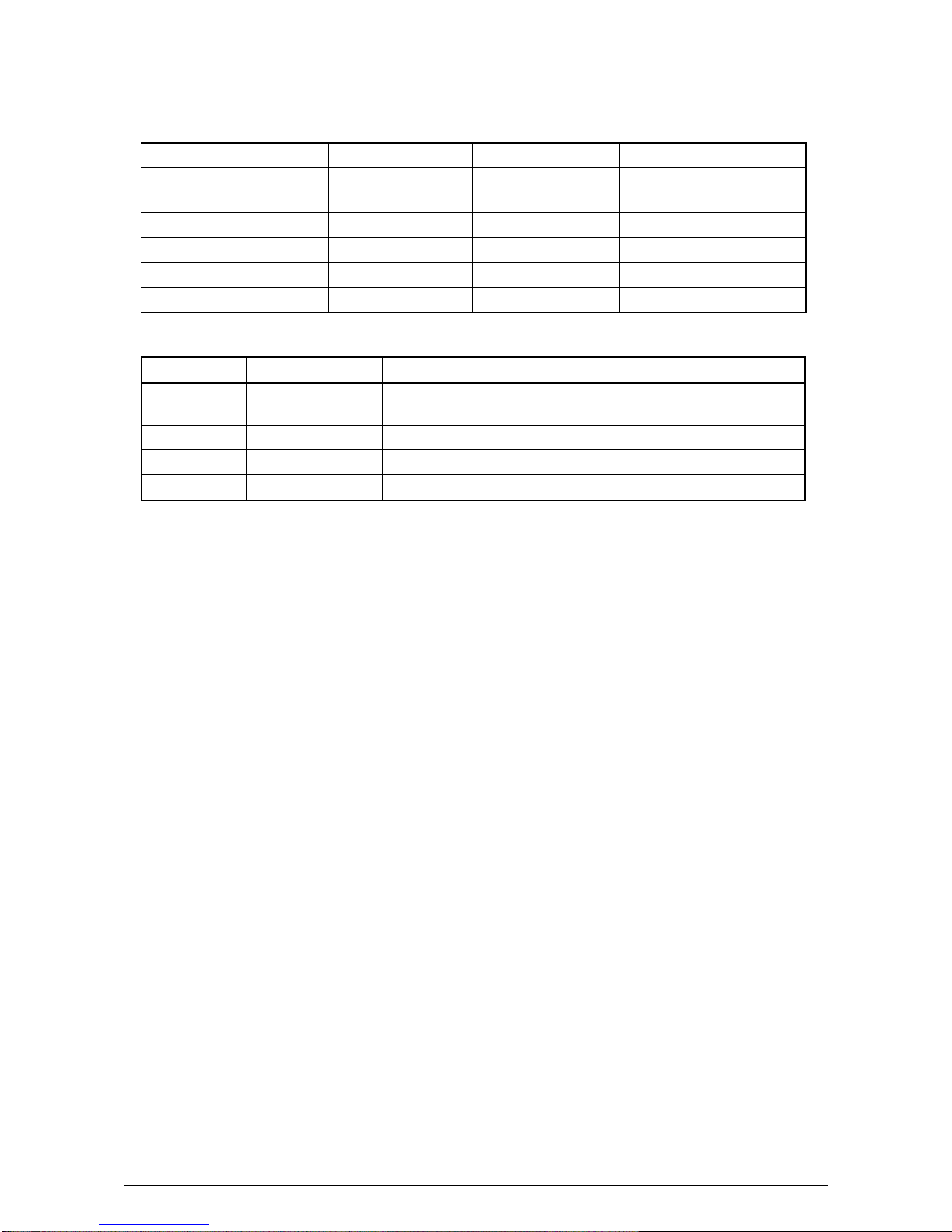

7.1 Resistance Check ........................................................................................................ 129

7.2 Parts Layout on Boards ............................................................................................... 134

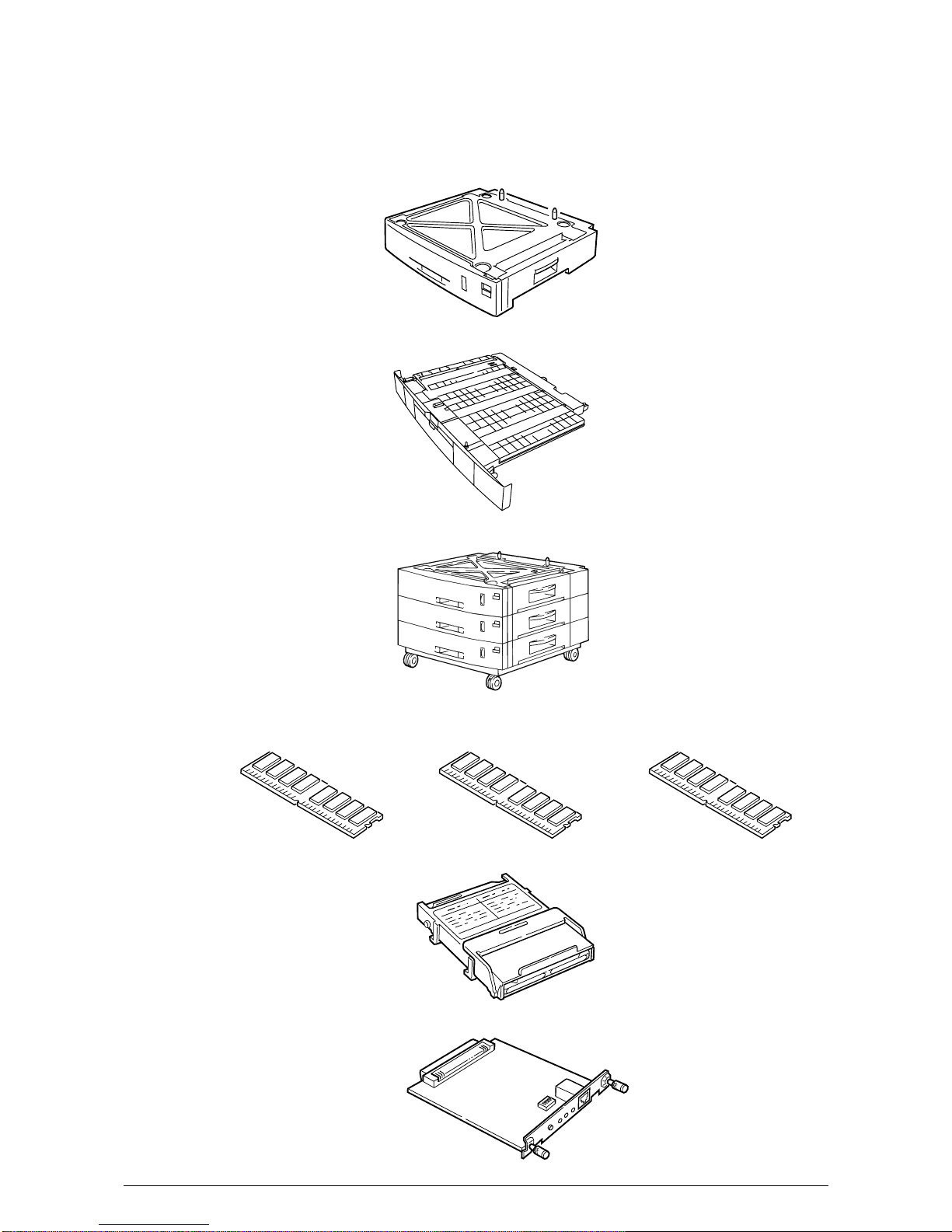

8. Parts List ...................................................................................................... 138