7

Step 3:

Run a Self Test

Before proceeding, run a self test to check that the

printer is operating correctly. This prints out a list of

available fonts.

1. Turn off the printer.

2. Press and hold MODE and LF while

turning on the printer. Release them

when

RELEASE SW

appears on the

second line of the display.

3. When the printer finishes initializing,

the display will prompt you to insert paper.

4. Place a letter size or larger sheet of paper on the

platform anywhere within the “Paper range when

Auto Align is ON” area.

The sheet feeds in. The first page of the test

prints and the page is ejected back out onto

the platform. The printer display then prompts

you to insert paper.

5. Remove the printed sheet and insert a new sheet.

The sheet feeds in and the remainder of the test

prints. The page is ejected.

The self test is complete.

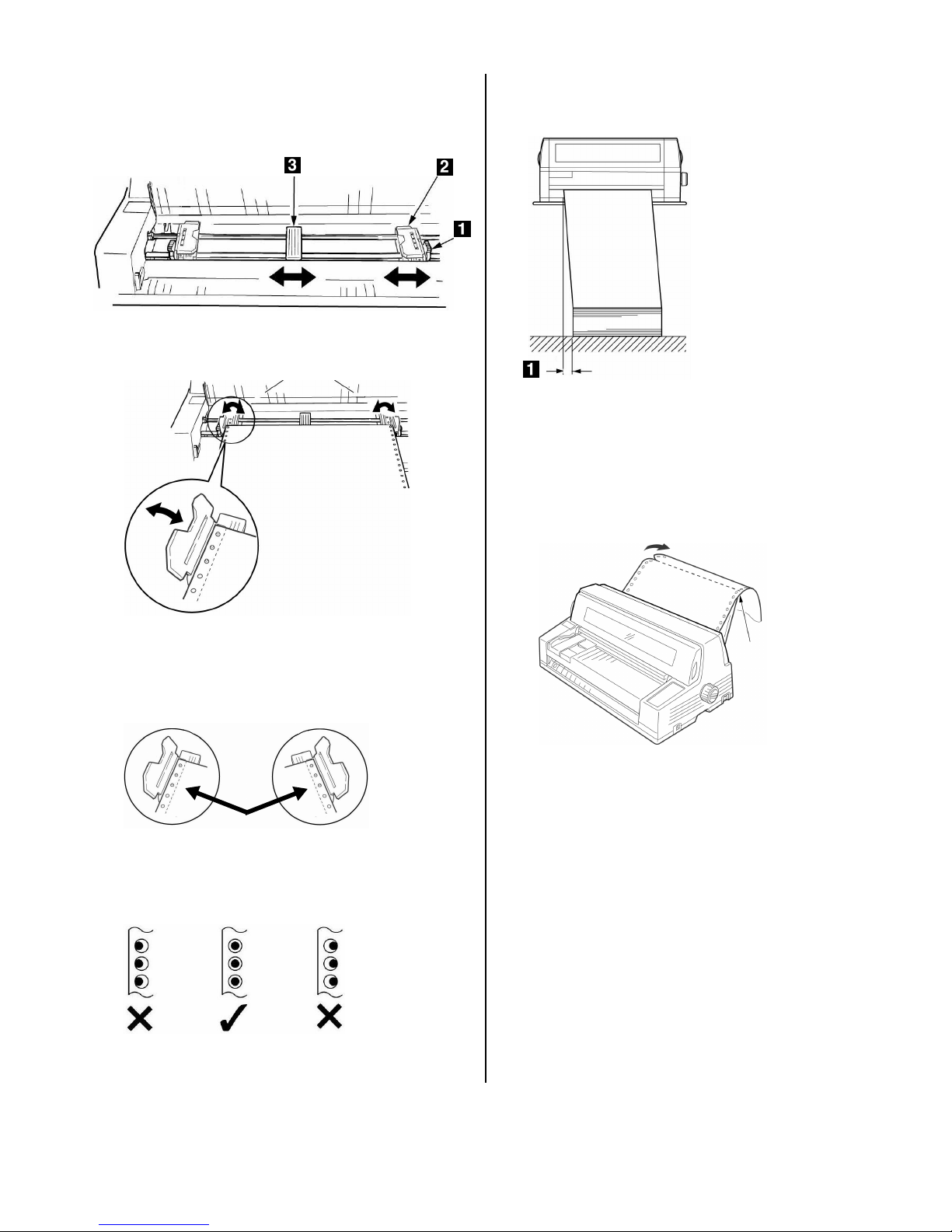

Step 4:

Load Paper

Individual Sheets/Forms

(“MANUAL”)

The printer is set at the factory for

• single sheets/forms (Manual Feed)

• Auto Align mode

• Normal print mode

• automatic printhead gap (Auto Gap)

Paper Specifications,

for Use with Auto Align Mode

Note

Printing envelopes requires use of the sheet

guide (

1

) instead of the Auto Align mode. See

your on-line User’s Guide for instructions on

turning off Auto Gap.

Minimum Print Margins

1/4-inch (6.4 mm) on all sides

Individual Sheets

•Size

– Minimum Width: 3.9” (100 mm)

– Maximum Width: 14.3” (364 mm)

– Minimum Length: 2.75” (70 mm)

– Maximum Length: 16.5” (420 mm)

•Weight

– Minimum:13.8 lb. US Bond (52 g/m

2

)

– Maximum: 55.8 lb. US Bond (210 g/m

2

)

MODE + LF.jpg

F5-11a.jpg