3 /

CONTENTS

1.CONFIGURATION.....................................................................................5

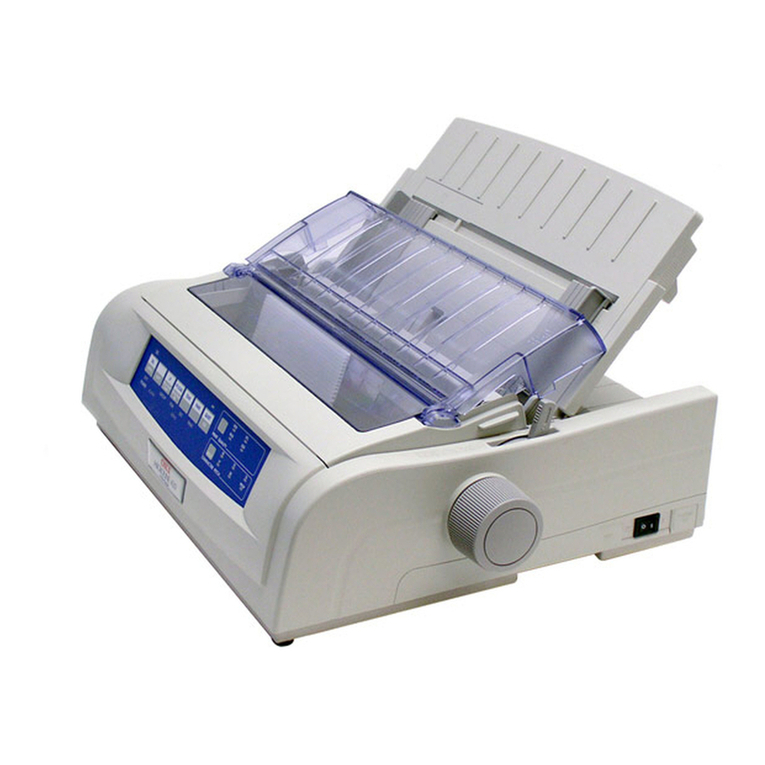

1.1Basic System Configuration...............................................................5

1.2Printer Specifications.........................................................................6

1.3Option Specifications.........................................................................7

1.4Basic Specifications...........................................................................8

2.THEORY OF OPERATION........................................................................11

2.1Electrical Operation...........................................................................11

2.1.1 Summary.................................................................................................11

2.1.2 Microprocessor and the peripheral circuit...............................................11

2.1.3 Initialization..............................................................................................20

2.1.4 Interface control.......................................................................................21

2.1.5 Parallel Interface Control.........................................................................21

2.1.6 Serial Interface........................................................................................22

2.1.7 Printing operation....................................................................................23

2.1.8 Printhead control.....................................................................................24

2.1.9 Print Compensation Control....................................................................26

2.1.10 Space motor control................................................................................26

2.1.11 Line feed.................................................................................................. 27

2.1.12 Bail, tractor switching, AG, ribbon motor control.....................................28

2.1.13 Operation Panel......................................................................................29

2.1.14 Alarm circuits...........................................................................................31

2.1.15 Power supply circuit................................................................................33

2.2Mechanical Operation........................................................................34

2.2.1 Printhead mechanism and operation.......................................................34

2.2.2 Spacing operation...................................................................................36

2.2.3 Head gap adjusting.................................................................................37

2.2.4 Ribbon drive............................................................................................40

2.2.5 Paper Feed Mechanism..........................................................................41

2.2.6 Bail Feed Mechanism..............................................................................45

2.2.7 Paper End Detection Mechanism............................................................47

3.PARTS REPLACEMENT...........................................................................49

3.1Precautions for Parts Replacement...................................................49

3.2Parts Layout.......................................................................................52

3.3How to Change Parts.........................................................................53

3.3.1 Cover-Assy-Access / Cover-Assy-Side (R) / Cover-Assy-Side (L)

/Cover-Assy-Front / Frame-Assy-Rear / Plate-Front (stuck)................54

3.3.2 Printer Unit..............................................................................................55

3.3.3 Control Block [Control Board (PMA Printed Board),

Driver Board (PDA Printed Board)].......................................................56

3.3.4 Power Supply Assy.................................................................................57

3.3.5 PG Cooling Fan.......................................................................................58

3.3.6 I/F Board (PHA Printed Board)................................................................59

3.3.7 AG Board (PGA Printed Board) / Connector Cord..................................60

3.3.8 AG Motor Assy........................................................................................61

3.3.9 Mini Pitch Belt..........................................................................................62

3.3.10 Tractor Change Motor Assy....................................................................63

3.3.11 Bail Motor Assy.......................................................................................64

3.3.12 LF Motor Assy.........................................................................................65