-3- -4-

ptun

st

3

2.

Hold and buttons for 1 second or longer without a workpiece in the area.

1.

MODE

Hold both for 1 sec. or longer

Blank display

Eco mode is ON. Turn OFF Eco mode. Refer to "5. Detailed Settings".

No power supplied or

the cable broken

Check the wiring, power supply voltage and

capacity.

Sensing/Detection

not possible despite

the minimum

threshold level

Detection set to a small

light level mode

Dust or dirt influences

The GIGA mode setting enhances the light level

and a larger incident level is displayed.

Incident light level

display fluctuation

Problem Cause Remedy

Cause Remedy

Error Name / Display

Dust or dirt, temperature

changes or vibration

Use the DPC function to stabilize the incident light level display.

The operation

indicator blinking

Mutual interference

or other reason

Check the Amplifier Units mounted in a group and

turn ON the power again.

Incident light level

displayed in a

negative value The differential

function is enabled.

Turn OFF the differential function.

Lost tracking of

the settings made

Reset the settings.

ー

The incident light

level has

deteriorated due

to dust or dirt.

Failed internal

data read/out

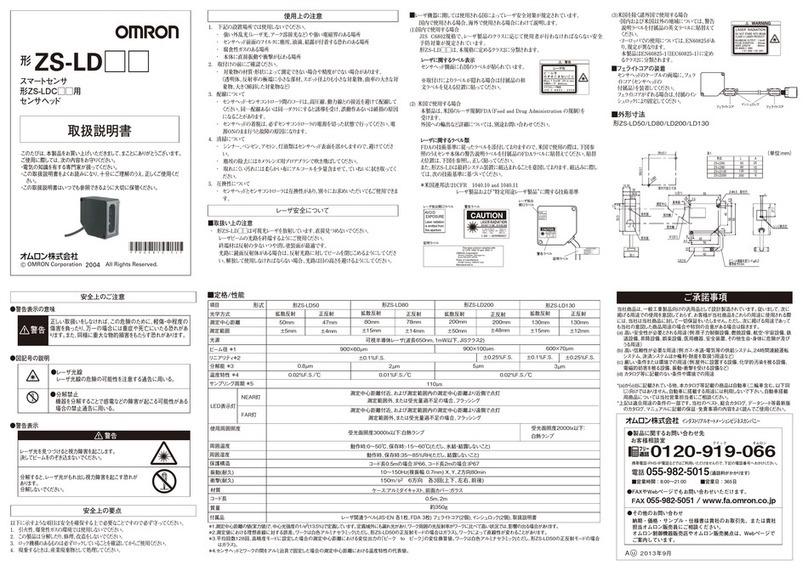

E3X-HD11, E3X-HD6, E3X-HD14 (NPN Type)

Load

The key lock

function enabled

Over current flowing

to the control output

2000

4000

*1: Either of E3X-CN11 (Master connector: three core) and E3X-CN12 (Slave connector: single core) can be used.

Model NPN Output

PNP Output

E3X-HD11

E3X-HD41

Number of Control Outputs

Connection Method

Light Source (Wavelength)

Power Supply Voltage

Power Consumption

Control Output

Protection Circuits

Ambient Illumination

Ambient Temperature Range

Ambient Humidity Range

Insulation Resistance

Dielectric Strength

Vibration Resistance

Shock Resistance

Material

1

Pre-wired Type M8 connector type

Wire-saving Connector Type*1

Red 4-element LED (625 nm)

12 to 24 VDC ±10%, ripple (p-p) 10% max.

Possible for up to 10 units *2

Case: Heat resistant ABS (ABS) / Cover: Polycarbonate (PC)

E3X-HD14

E3X-HD44

E3X-HD6

E3X-HD8

Perform the procedure with a workpiece in the area for reflective model setting.

If the setting is made after position tuning, set both the through-beam model and

reflective model with a workpiece.

Troubleshooting

Troubleshooting

Error Display

Power Tuning

DPC Function

Setting Reset

User Save Function

Enable/Cancel

(This procedure)

Enable

Key Lock Function

Zero Reset Function

User Reset Function

4-1

Ratings and Specications

4-3

Normal: 720 mW max. (current consumption: 30 mA max. at power

supply voltage of 24 VDC; 60 mA max. at power supply voltage of 12 VDC)

Power supply reverse polarity protection, output short-circuit protection and

output reverse polarity protection

Mutual Interference Prevention

Operating and storage: 35% to 85% (with no condensation)

20 MΩ min. (at 500 VDC megger)

1,000 VAC at 50/60 Hz for 1 minute

Receiver side: Incandescent lamp: 20,000 lux max. / Sunlight: 30,000 lux max.

Power-saving ECO: 530 mW max. (current consumption: 22 mA max. at power

supply voltage of 24 VDC; 44 mA max. at power supply voltage of 12 VDC)

Load power supply voltage: 26.4 VDC; NPN/PNP open collector;

load current: 50 mA max.; residual voltage: 2V max.

rst

L/D

Hold button and then hold

button for 3 seconds or longer.

Hold button and then hold button for 3 seconds or longer.

A timer value can be set after pressing

button when a timer menu (other display than

"----") is displayed. Use button to set the

time.

(1 to 9999ms in 1 ms steps; the initial value: 10 ms)

Press button in [ ] menu, then use

button to set the percentage tuning level.

(-99% to 99% in 1% steps; the initial value: -10%)

Disables all button operations. [ ] is displayed when the button is pressed.

Changes the incident light level to "0". The threshold level is also shifted accordingly.

Select [ ] in and press button.

Select [ ] in and press button.

Caution is required; the output is inverted if button is pressed rst.

1.

Initializes all the settings by returning them to the factory defaults.

2.

3.

MODE

Saves the current settings.

Select [ ] in and press button.

Select [ ] in and press button.

Select [ ] in and press

button.

Select [ ] in and press button.

MODE

Reads out the saved settings.

2.

3.

MODE

UP/DOWN

UP/DOWN

UP/DOWN

Incident light level setting: The Step 1 incident level is adjusted to the power tuning level.

Threshold setting: Not changed. If the value is low, it will be set to the minimum

value in which an output is turned ON/OFF correctly.

Refer to "2-3 Smart Tuning Error" for error displays.

Refer to "2-3 Smart Tuning "

DPC Error*

*The DPC indicator blinks.

Wipe the dust off the Fiber Unit detection surface or

other relevant areas and recover the original incident

light level. Then, perform Smart Tuning.

Turn ON the power again. Reset the

settings if the error is not corrected.

Cancel the key lock function.

Check the control output load and adjust it within the

rated value. Check for a load short-circuit.

• Steps 1 and 2 can be reversed.

• The DPC function will be disabled when a smart tuning error occurs, differential function with

maximum sensitivity tuning is performed, or the rst incident light level of the positioning

tuning is low.

• The incident light level is corrected to the power tuning level to maintain stable threshold and

incident light levels. This provides stable detection regardless of the incident level changes

caused by dirty sensor head, position error, or temperature changes.

Approx. 65 g Approx. 22 gApprox. 20 g

Maintenance

4

E3X-HD41, E3X-HD8, E3X-HD44 (PNP Type)

12 to 24 VDC

Black:

Control Output

Black:

Control Output

Brown

Blue

Brown

Blue

12 to 24 VDC

Input/Output Circuit Diagram

4-2

1.

L/D

2.

3.

Cancel

0

1999

-

No digital display

The zero reset function

is enabled. Cancel the zero reset function.

MODE

UP/DOWN

MODE

UP/DOWN

MODE

UP/DOWN

Current Over

Weight (Main Unit Only)

Maximum connectable units

EEPROM Error

Lock ON

Time

Refer to "4-2 Input/Output Circuit Diagram"

Refer to "1-2 Mounting Amplifier Unit"

Refer to "4-2 Input/Output Circuit Diagram"

and "4-3 Ratings and Specications"

Item

Threshold Value

Control Output

Initial Value

55

(a)

(b)

(c)

(d)

(e)

(a)

(b)

(c)

(d)

(e)

L-on

* Settings for other functions are returned to

the detailed setting initial values.

User-saved settings are retained.

Smart Tuning is canceled.

Hold button for 3 seconds or longer to enter SET mode.

MODE

dp<

%n

hs

500

stnd

shs

dp<

%ff

----

9999

MODE

MODE

MODE

MODE

Detection Function Response

Time

Light Level

STND

Standard Mode

SHS

Super High-speed

Mode*

GIGA

Giga Mode

HS

High-speed Mode

1 ms

50 µs

55 µs

16 ms

250 µs

12 times

0.25 times

1 time

1 (Standard)

2. Detection Function

per

%ff

per

%n

%ff

per

p-b

bar

3. DPC Function

4. Timer Function

UP/DOWN

9. Inverted Display

8. Digital Display

7. Differential Function

6. Percentage Tuning

MODE

MODE

MODE

MODE

MODE

One-shot Timer

Keeps the output ON for

a specified time regardless

of the workpiece size

variations.

T

T

T

T

T

T

Off-delay Timer

Holds the output ON for

detection by PLC when

the detection time is too

short.

On-delay Timer

Delays the output ON

after detection.

Incident Light

No Incident Light

Incident Light

No Incident Light

Incident Light

No Incident Light

ON

OFF

ON

OFF

L-ON

D-ON

ON

OFF

ON

OFF

L-ON

D-ON

ON

OFF

ON

OFF

L-ON

D-ON

%ff

B

A

SET mode provides the function settings described hereafter. The initial display shown

after transition from one function to another represents the factory default.

UP/DOWN

UP/DOWN

UP/DOWN

UP/DOWN

(IncidentLightLevelExample)

Differential Setting Response Time

1

2

3

4

5

250 μs

500 μs

1 ms

10 ms

100 ms

Detailed Settings

5

dflt

MODE

UP/DOWN

1. Function Selection

e<%

%ff

e<%

%n

UP/DOWN

MODE

UP/DOWN

Indicators (Green and Red digital displays)

turn OFF in approx. 10 seconds after a key

operation.

10. Eco Function

UP/DOWN

Use button to specify the response time.

UP/DOWN

5. Power Tuning Level

Detects if the absolute value of the incident light level

change of the set response time is larger than the

threshold value. The display shows the change of the

incident light level of the set response time in red.

Smart Tuning is canceled if the detection mode

is changed.

*The communication and mutual interference

prevention functions are disabled when the

detection mode is set to Super High-speed Mode.

(a)

(a)

(b)

(c)

(d)

(b)

(c)

(d)

(a)

(b)

(c)

(d)

Setting Output Timer

Changing the Target Incident Light Level

(Power Tuning Level)

Detecting Transparent or Small Workpiece

Changing Digital Display in RUN Mode for

Specific Purpose

Detecting Incident Light Level Change

10

%n-d

10

std

B

A

Mounting Amplifier in Inverted Direction

Saving Power Consumption

Function Setting Description

Function Setting Description

Changing Functions to Set in SET Mode

[ ]: Functions 1. to 5. can be set.

[ ]: Functions 1. to 10. can be set.

Changing Light Level and Response Time

Stable Detection Regardless of Incident Light

Level Change

Setting Threshold using a Small or Fast Moving

Workpiece

Adjusting Optical Axis

Checking the Channel No. in Group Mounting

The ratio of the incident light

level to the threshold is

displayed in red digital figures.

Holds the peak incident light

level and displays it in green

digital figures.

Checking the Channel No. in

Group Mounting

Displays the current level in the

80 to 120% range against the

threshold value (100%).

A

Function Selection: [ ]

Threshold

Threshold

Peak Light

Level

Peak Light

Level

Bottom Light

Level

Light Level

Checking a Margin Against Threshold

Holds and displays the minimum

value of the peak of the light

incident and the maximum value

of the bottom of the light interruption.

Ch. No. Light Level

Setting for Intuitive Analog Display

120%100%80%

The zero reset function is canceled when either of the DPC function/differential

function/Smart Tuning is performed.

APC (Auto Power Control) Always ON

16 units

MODE

UP/DOWN

Inverts the display upside down.

The digital display shows the threshold value in

red, and light incident level in green.

Refer to "4-1 Troubleshooting"

10 to 55 Hz with a 1.5-mm double amplitude for 2 hours each in X, Y and Z directions

500 m/s2, for 3 times each in X, Y and Z directions

*2: Mutual interference prevention is only possible for up to 6 units, if the E3X-DA-S/MDA sensors applied with

power tuning are grouped with this sensor.

*3: The communication and mutual interference prevention functions are disabled when the detection mode is set to

Super High-speed Mode

150p

3000

3500

3000

L/D

Caution is required; the output is inverted if button is pressed rst.

L/D

20004000

UP/DOWN

Use button to set the power tuning level.

[100 to 9999 in 1 steps; the initial value: 9999]

Perform Smart Tuning.

Set the DPC function ON in SET mode.

1.

Refer to "2-3 Smart Tuning"

内部受光量

Internal Incident Light Level

Incident Light

Level

Displayed Incident Light Level

Threshold

Level

Stabilizes the displayed

incident level by correcting

internal incident level changes.

The DPC indicator turns ON

when the DPC function is

effective.

The displayed incident level

decreases and the DPC

indicator starts blinking when

incident level correction is not

possible.

* Press either of UP/DOWN.

Operating: Groups of 1 to 2 Ampliers: −25°C to 55°C

Groups of 3 to 10 Ampliers: −25°C to 50°C

Groups of 11 to 16 Ampliers: −25°C to 45°C

Storage: −30°C to 70°C (with no icing or condensation)

Convenient Setting Features

Restore from the Incident Level Changed due to Dust and Dirt

Stable Detection Regardless of Incident Level Change due to Dust and Dirt

Reset Settings

Save or Read Settings

Prevent Mis-operation

Reset Incident Light Level to "0"

Setting is Completed Refer to " Detailed Settings".

Refer to " Detailed Settings".

Refer to " Detailed Settings".

Refer to " Convenient Setting Features"

Refer to " Convenient Setting Features"

Refer to " Convenient Setting Features"

Refer to " Convenient Setting Features"

Refer to " Convenient Setting Features"

Refer to " Convenient Setting Features"

Refer to " Convenient Setting Features"

Refer to "2-3 Smart Tuning"

Refer to " Detailed Settings".

Sensor Main Circuit

Sensor Main Circuit

Load

Hold both for 3 sec. or longer

Hold both for 3 sec. or longer

Hold both for 3 sec.

or longer Hold both for 3 sec.

or longer

Light Level

Ratio

OMRON Corporation

Suitability for Use

EUROPE

OMRON EUROPE B.V. Sensor Business Unit

Carl-Benz Str.4, D-71154 Nufringen Germany

Phone:49-7032-811-0 Fax: 49-7032-811-199

NORTH AMERICA

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg,IL 60173-5302 U.S.A.

Phone:1-847-843-7900 Fax : 1-847-843-7787

ASIA-PACIFIC

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road #05-05-08(Lobby 2),

Alexandra Technopark, Singapore 119967

Phone : 65-6835-3011 Fax :65-6835-2711

THE PRODUCTS CONTAINED IN THIS SHEET ARE NOT SAFETY RATED.

THEY ARE NOT DESIGNED OR RATED FOR ENSURING SAFETY OF

PERSONS, AND SHOULD NOT BE RELIED UPON AS A SAFETY

COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES.

Please refer to separate catalogs for OMRON's safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or

regulations that apply to the combination of the products in the customer's

application or use of the product.

Take all necessary steps to determine the suitability of the product for the

systems, machines, and equipment with which it will be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

See also Product catalog for Warranty and Limitation of Liability.

CHINA

OMRON(CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Phone : 86-21-5037-2222 Fax :86-21-5037-2200

OCT. 2009

500

6000

125

(a)

(b)

(c)

(a)

(b)

(c)

UP/DOWN

3

2

5

4

The incident light level in setting mode is a

reference value. It may be changed when

switched to detection mode.

When the differential function is enabled,

the detection function setting is disabled.

Smart tunings except power tuning are disabled.

The adjustment range of powr tuning is approx.

1 to 1/100 times.

Function Selection: [ ]

D

2000

8000

Refer to " Convenient Setting Features

- Power Tuning"

NPN

PNP