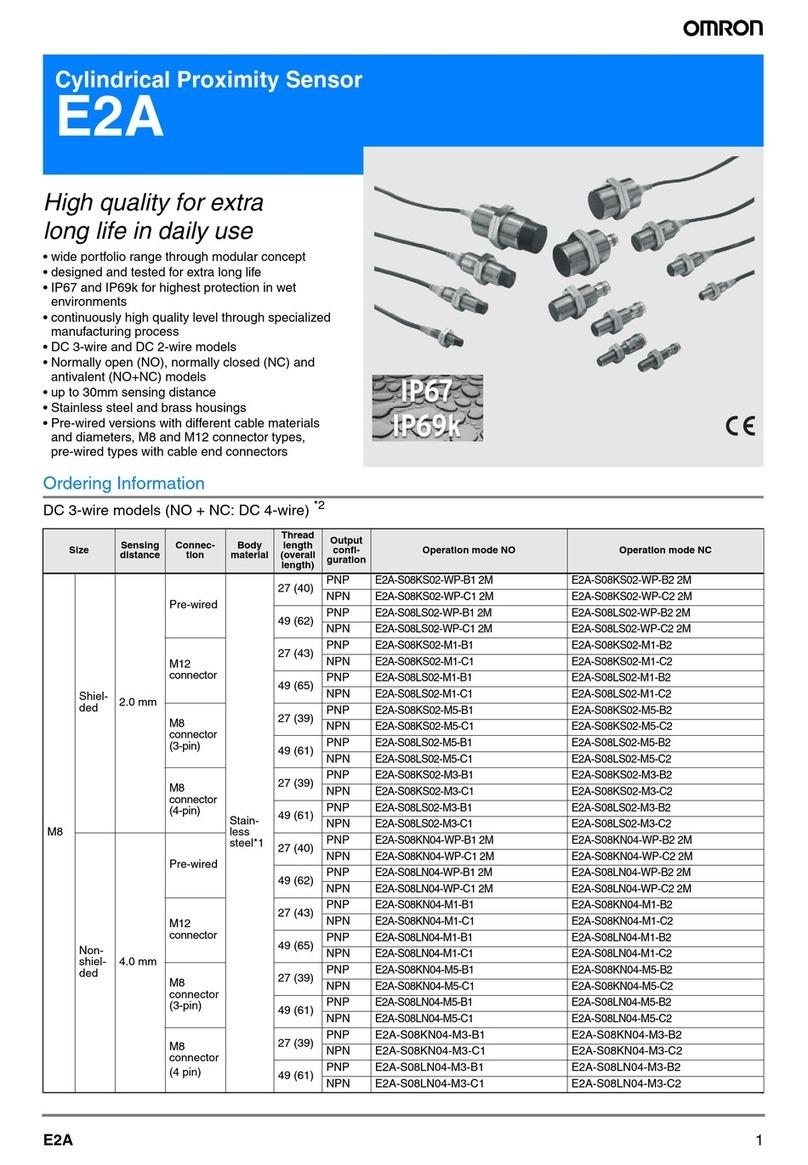

F3W-D

•The distance between two adjacent sets of Sensors must be at

least l1or l2, which does not cause mutual interference between two

Sensors with the same frequency setting. l1or l2is at least 1.5 times

the distance shown in Parallel Operating Range of the Engineering

Data.

•Install a baffle so that there will not be mutual interference between

Sensors with the same frequency setting. (See Figure 1.)

A light reflection from the wall or floor may go around a baffle and

reach the Receivers. Install a baffle so that it will also block any light

reflection. (See Figure 2.)

●Wiring Precautions

Connection

•Before turning ON the power, make sure that the supply voltage is

within the maximum allowable voltage range.

•Always connect the sync lines.

•Be very careful not to get metal chips in the connector, especially

during wiring.

•Incorrect wiring may damage the equipment. Make sure that the

cable length and routing are appropriate to prevent the connectors

and cables from getting disconnected.

•Always leave the operation cover closed during operation.

•Applying excessive force to the mode switch may result in damage.

Do not apply a force of more than 5 N.

Cables

Make sure that the bending radius is 25 mm or more.

●Installation Precautions

Installation

•Install the Sensor so that its sensing face will not receive light from

the sun, fluorescent lamps, incandescent lamps, and other light

sources.

•Do not strike the Sensor with a hammer or any other tool during

installation, otherwise the internal circuits of the Sensor may be

damaged.

•Install the Emitter and Receiver in the same orientation as shown in

the following figure. (The cables must be in the same direction.)

•Use M4 screws to secure the Sensor body.

•Secure the case to a tightening torque of 1.2 N·m or less.

Reflection from Wall or Floor

If the Emitter and Receiver are installed as shown in the following

illustration, all the axes may not be interrupted due to light reflection

from the floor or wall. Make sure that the Emitter and Receiver detect

the sensing object properly before using the F3W-D in actual

operation.

Side View Top View

●Adjustment

Operation and Stability Status Display

•The following illustration shows the indicator status corresponding

to each incident level.

•Install the Receiver so that the green stability indicators are both

ON in light receiving status.

Error Display

F3W-D052 Picking Sensors are provided with only

one error display mode.

If an error occurs, the indicator on the Sensor’s

Receiver, as indicated by the arrow in the diagram

on the right, will flash.

The error indicated in this example is a

synchronization error.

The possible causes are as follows:

1. The sync line is not connected.

2. The sync line is shorted with another line.

3. UNI-WIRE communications are not being

performed (when an F3W-D052U UNI-WIRE

Direct Connection Model is being used).

Emitter

l2

Receiver

Emitter Receiver

Distance X

Vertical Installation Horizontal Installation

l

1

Distance X

ReceiverEmitter

ReceiverEmitter

Emitter Receiver Emitter Receiver

Baffle

Wall

Emitter Receiver Emitter Receiver

Baffle

Figure 2

Wall

ReceiverEmitter

ReceiverEmitter

Baffle

Figure 1

Emitter Receiver Emitter Receiver

Sensing object

Floor

Light reflection

Wall

Emitter Receiver

Emitter Receiver

Light-shielded area

Unstable light-

receiving area

Stable light-

receiving area

*

Operating level

×1.2

Operating level

Stability indicator

(green)

* If the Receiver is set to the stable light-receiving area, it will become more

resistant to environmental fluctuations such as temperature, voltage, dust, and

setting deviation after installation. For applications where a stable light-receiving

area is not obtained, attention must be paid to environmental fluctuations.

Operation indicator (orange)

Light-ON Dark-ON

ON

OFF

ON

OFF ON

OFF

Amount of

light received

http://www.ia.omron.com/ 9

(c)Copyright OMRON Corporation 2008 All Rights Reserved.