B5WC Built-In Color Sensor User's Manual ( E612-E1-01) 4

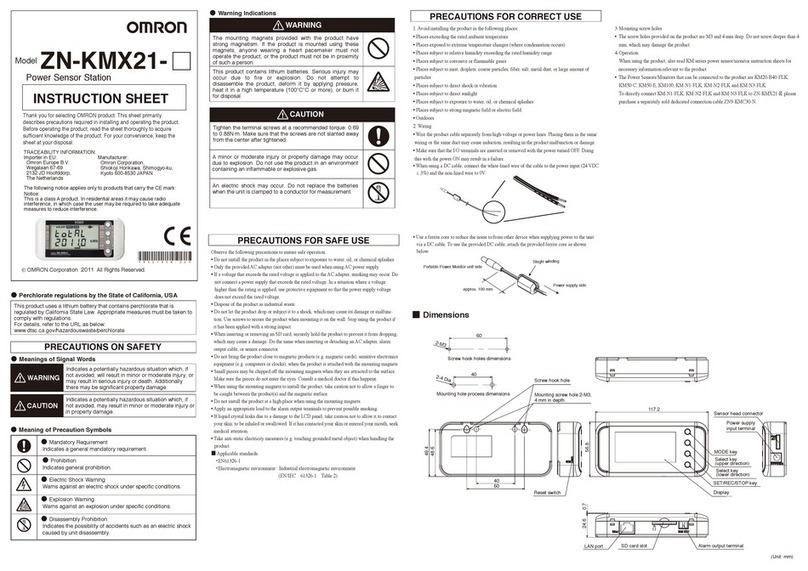

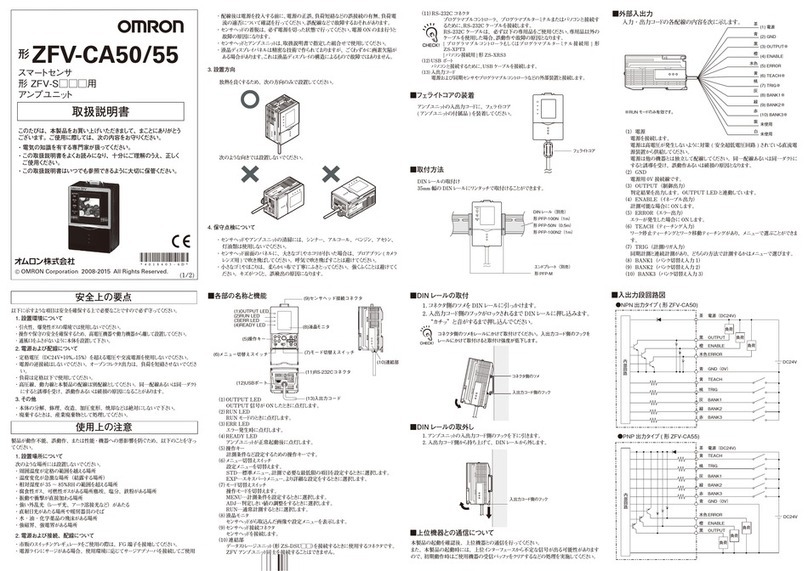

●Mounting

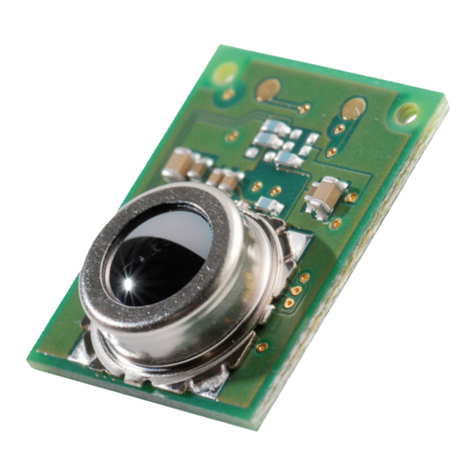

1. This sensor is designed to be built into equipment.

Design the equipment structure so that ambient light

does not enter into the sensor. When using the

equipment where the sensor will be influenced by

ambient light, install it so that the sensor will not be

affected by ambient light.

2. Mount the sensor securely on a flat surface. To retain

the sensor with screws, use M3 screws (to prevent the

screws from loosening, use a spring washer and a flat

washer with a diameter of 6mm). Use a tightening

torque of 0.54 N⋅m max.

3. Take care that nothing comes into contact with the

detected part of the sensor. Damage to the sensing

element will result in poor performance.

4. Before using the sensor, check to make sure that it has

not become loose due to vibration or shock.

5. When using the sensor with a moving part, secure the

part of the cable that is pulled out so that stress will not

be directly applied to it.

●Wiring

Surge Prevention

1. If there is a surge in the power supply, try connecting a

Zener diode or a capacitor (with a capacitance of 0.1 to

1 μF), depending on the operating environment. Use the

sensor only after confirming that the surge has been

eliminated.

2. Do not use a small inductive load, such as a relay.

3. Separate the wiring for sensors from high-voltage lines

or power lines. If the wiring is routed in the same conduit

or duct as such lines, the sensors may malfunction or

may be damaged by inductive interference.

4. When attaching the connectors, make sure that they

are inserted into the housing properly.

●Handling during Wiring

Surge Prevention

1. If a force is applied to the connection area between the

terminal and connector by bending or pulling the cable

after the wiring is completed, the connector contact part

or connection area with the cable may be damaged,

resulting in contact failure.

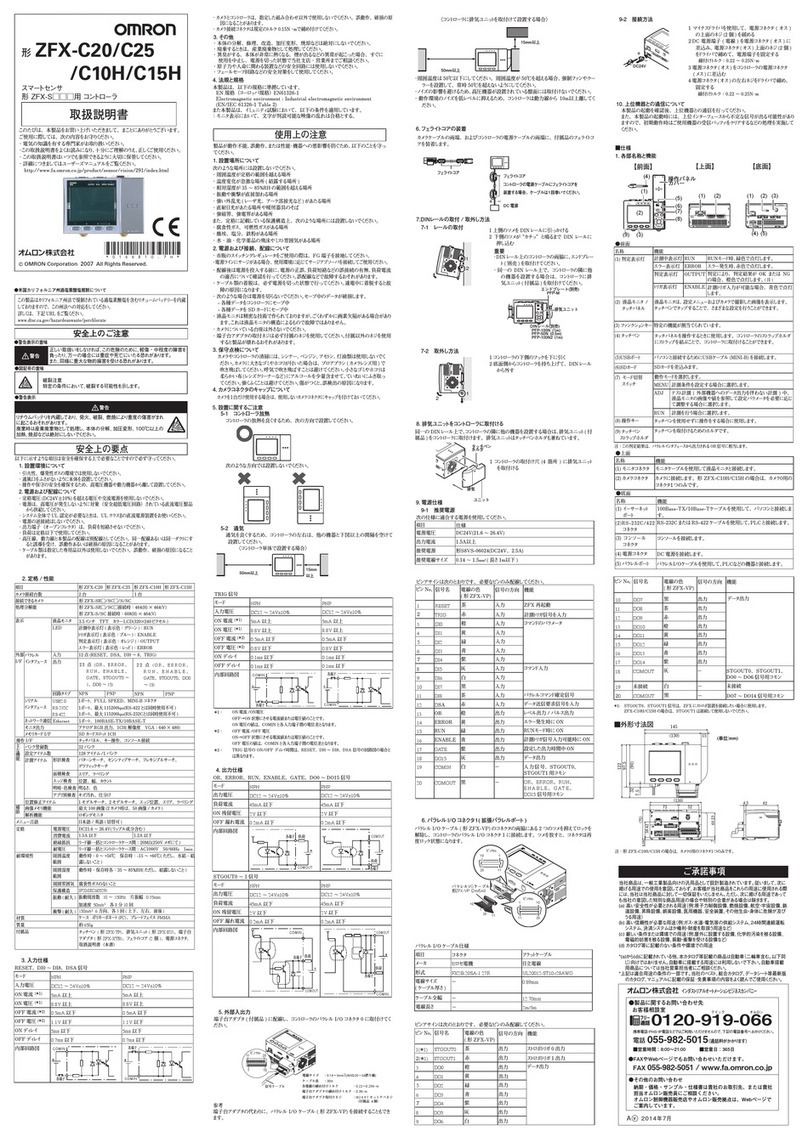

2. Make sure that a stress (external force) as shown in the

figure below is not applied to the connection area

between the terminal and connector when routing and

connecting cables or harnesses.

3. Do not perform cord wiring when power supply voltage

is applied. Doing so may result in breakage.

●Design

Modulated-light sensors

When designing, give proper consideration to the

influence of the power supply and cable length.

Since this sensor is a modulated-light sensor, it is more

easily affected than non-modulated light sensors.

Reasons for Interference from Power and Cable

Length on the sensors with Modulated Light

An LED emitter is pulse-lighted to produce modulated

light.

A large current momentarily flows to the sensor in sync

with this pulse timing. This causes a pulsating

consumption current. A photoelectric sensor incorporates

a capacitor with sufficient capacity, and is virtually

unaffected by the pulse of the consumption current. With a

small sensor, however, it is difficult to have a capacitor

with a sufficient capacity. Accordingly, when the cable

length is long or depending on the type of power source, it

may become impossible to keep up with the pulse of the

consumption current and operation may become unstable.

Countermeasures

Adding a Capacitor

Attach a capacitor of 10 μF min. as close as possible to

the sensor when wiring.

(Use a capacitor with a dielectric strength that is at least

twice the sensor's power supply voltage. Do not use

tantalum capacitors. A short-circuit may cause the

capacitor to ignite due to the large current flow.)

Precautions for Correct Use