Omron FZ2 Series User manual

Other Omron Accessories manuals

Omron

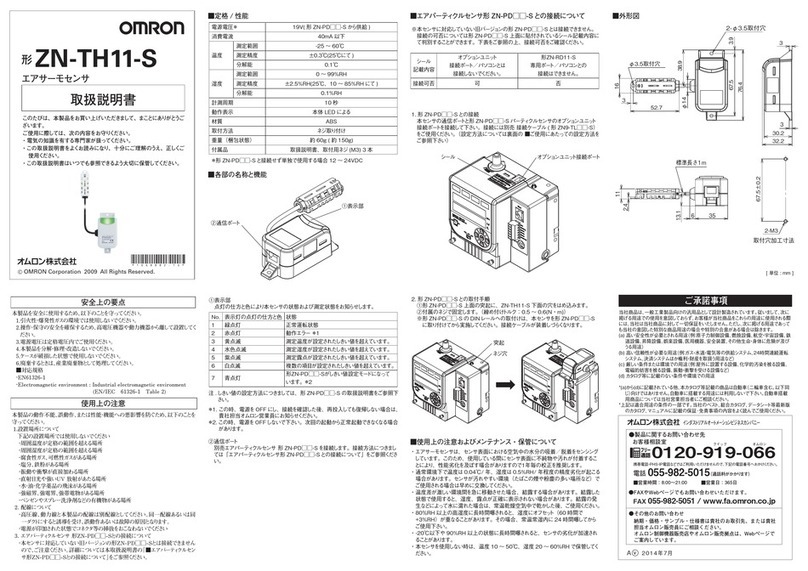

Omron ZN-TH11-S User manual

Omron

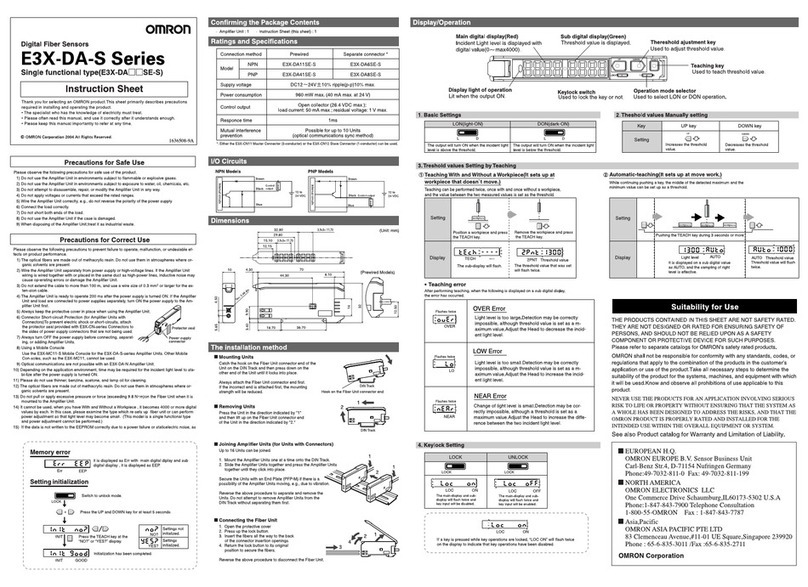

Omron E3X-DA-S Series User manual

Omron

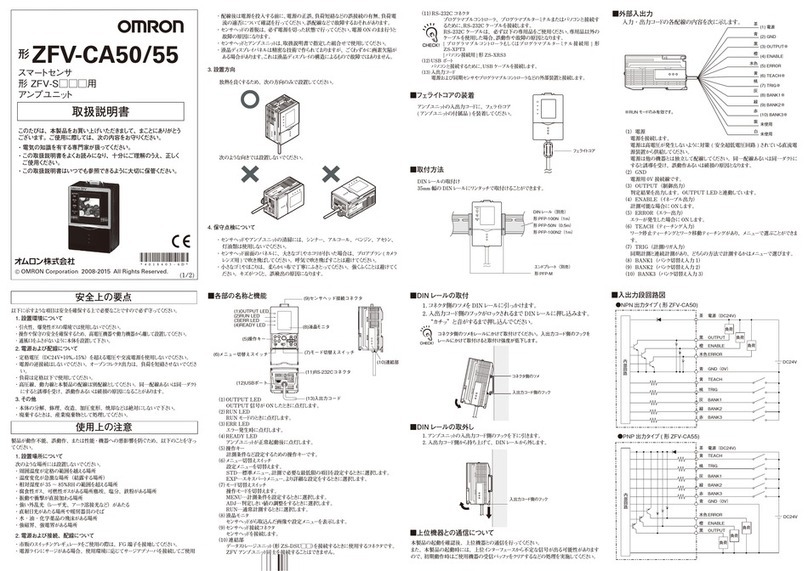

Omron ZFV-CA50 User manual

Omron

Omron F210 User manual

Omron

Omron E3S-A - User manual

Omron

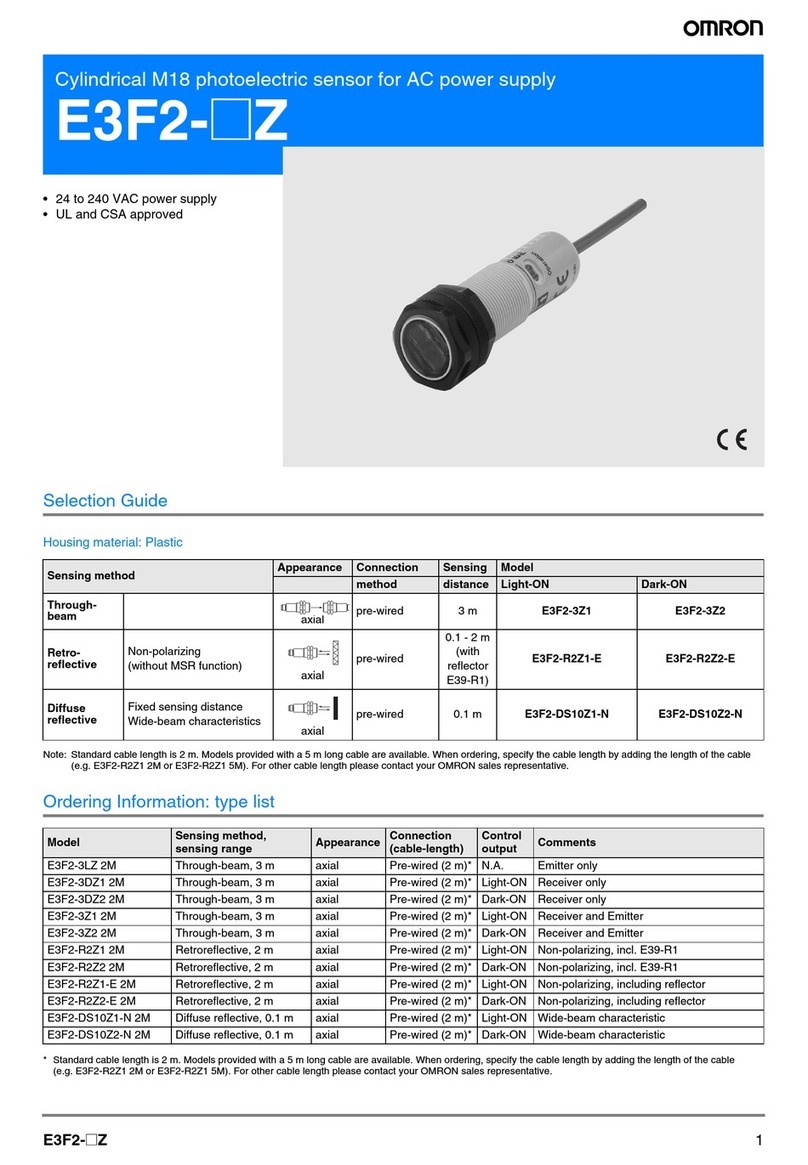

Omron E3F2-Z User manual

Omron

Omron E3G-L1 User manual

Omron

Omron E3Z series User manual

Omron

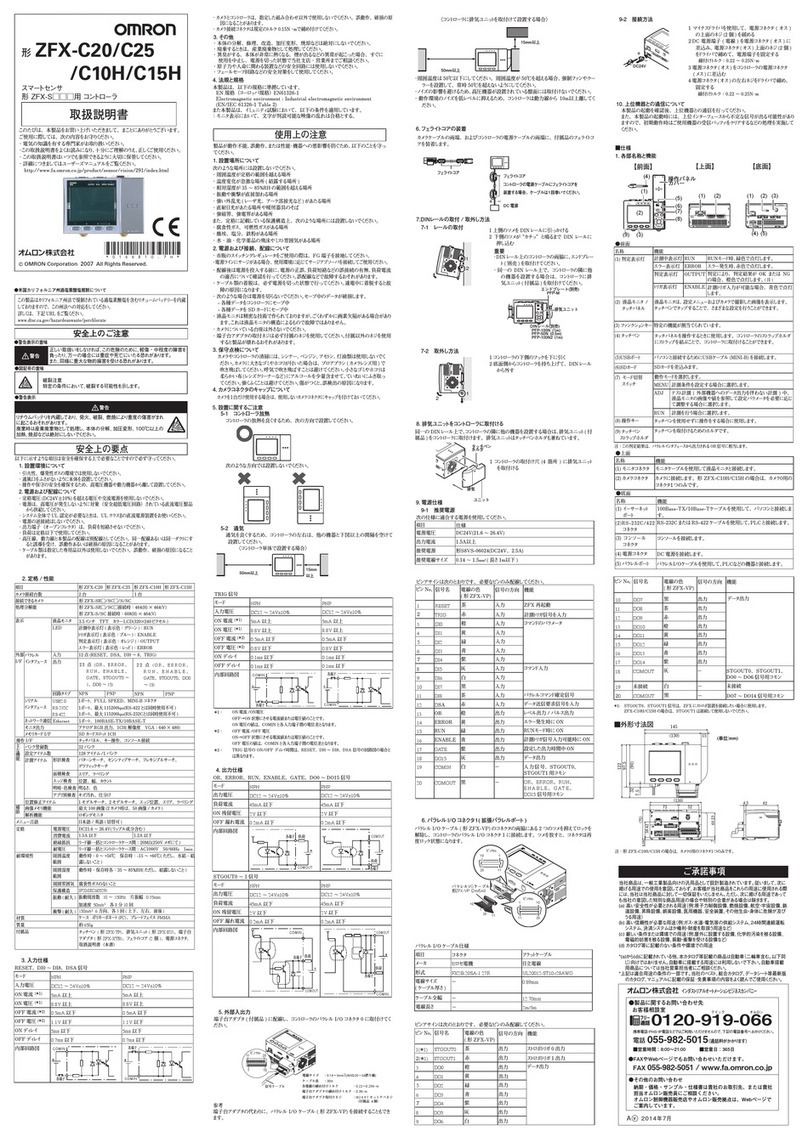

Omron ZFX-C20 User manual

Omron

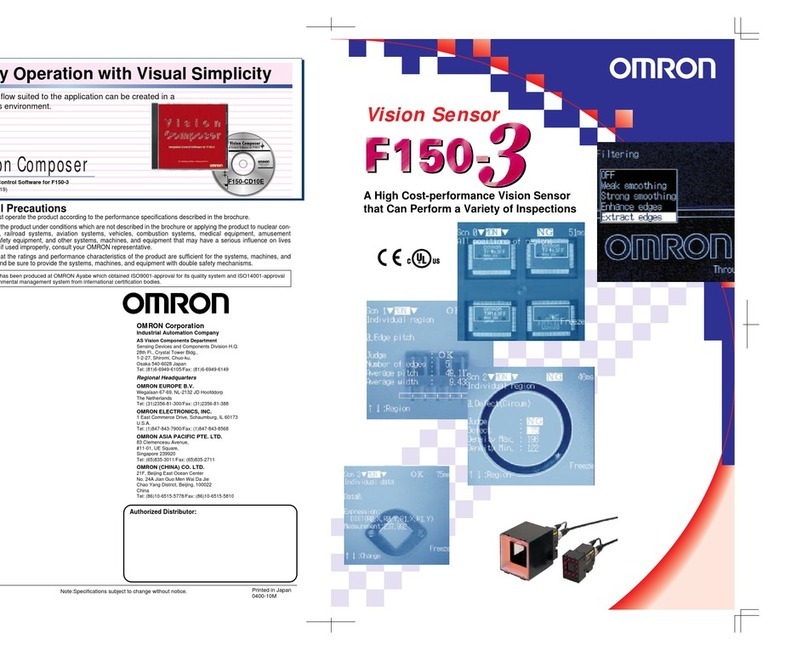

Omron F150-3 - Instruction Manual

Omron

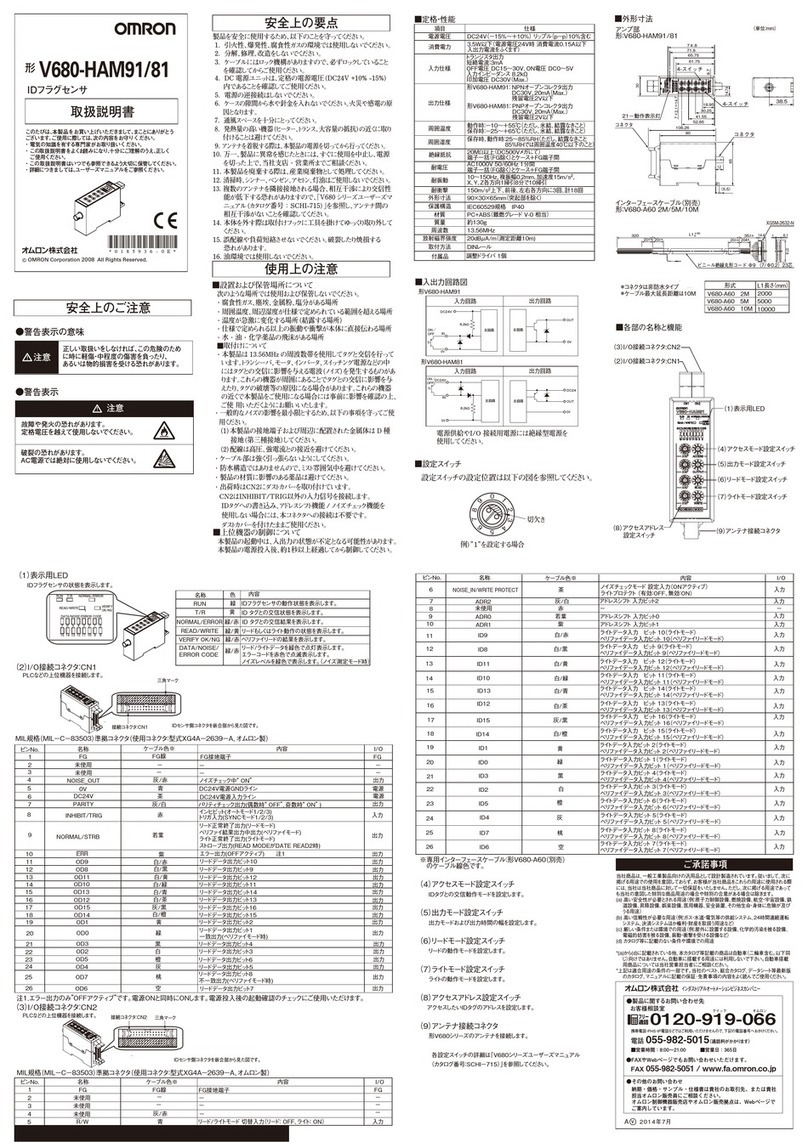

Omron V680-HAM91 User manual

Omron

Omron ZW-XC7 User manual

Omron

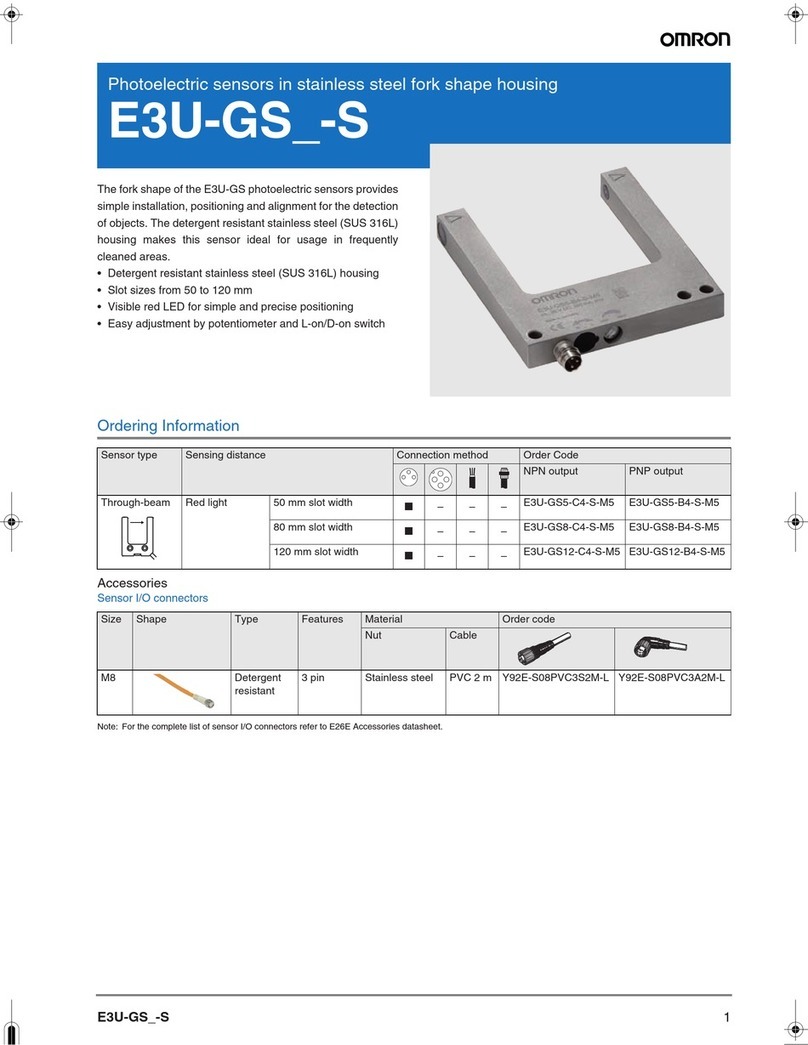

Omron E3U-GS-S User manual

Omron

Omron ZX2 Series How to use

Omron

Omron E3T - User manual

Omron

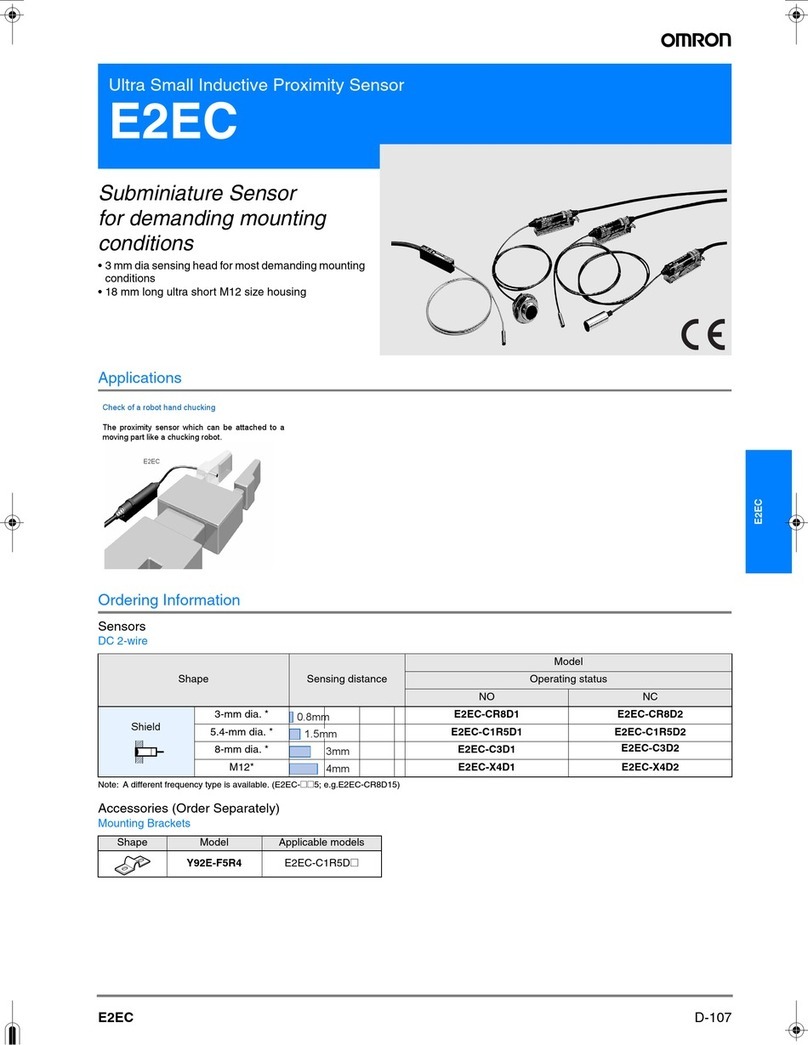

Omron E2EC - User manual

Omron

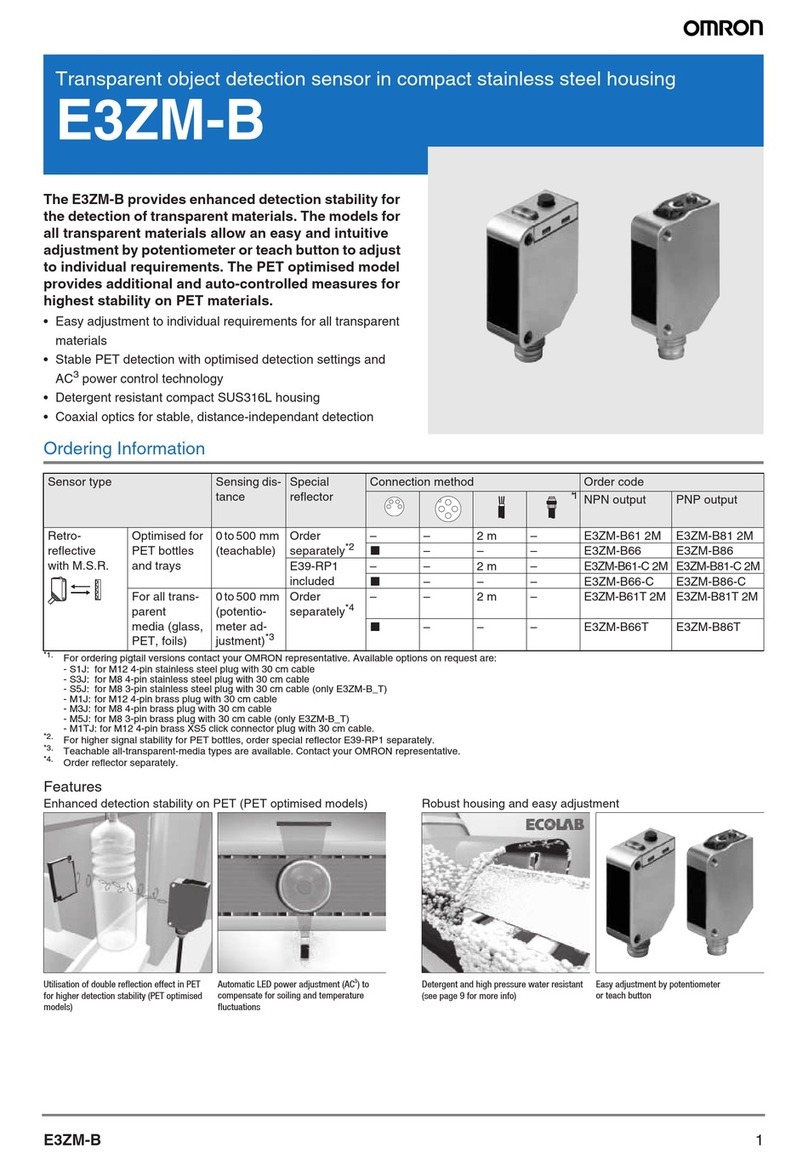

Omron E3ZM-B - User manual

Omron

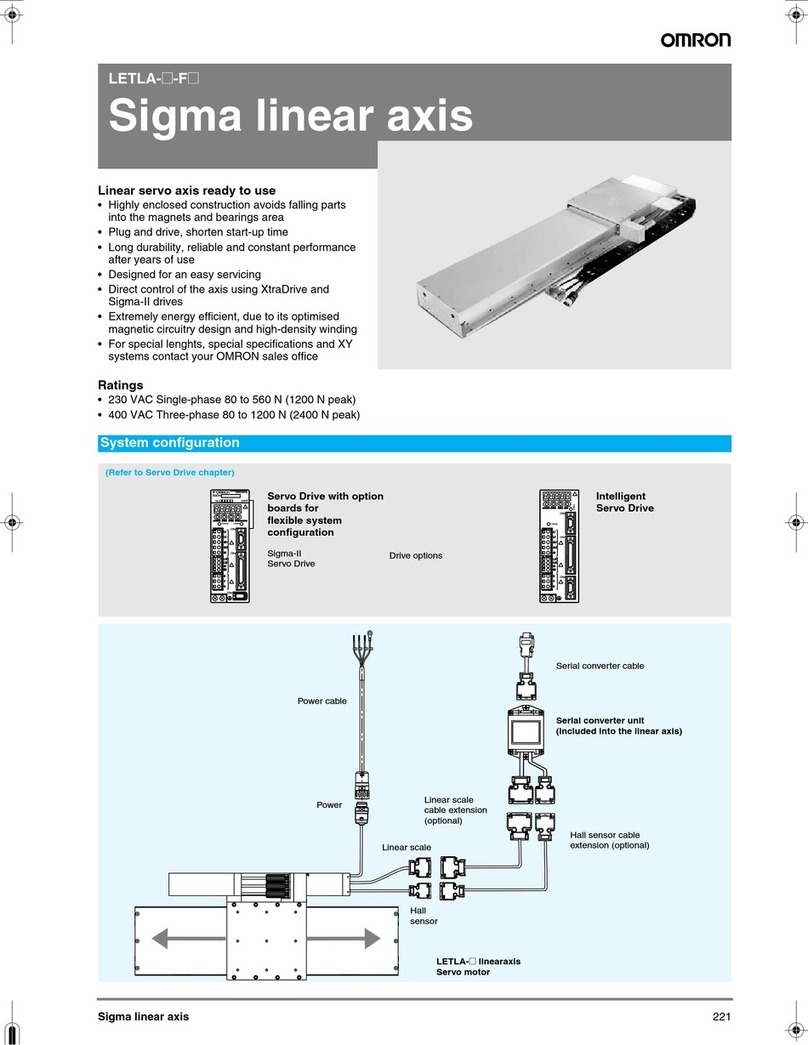

Omron SIGMA LINEAR AXIS - User manual

Omron

Omron ZW-S7010 Operating instructions

Omron

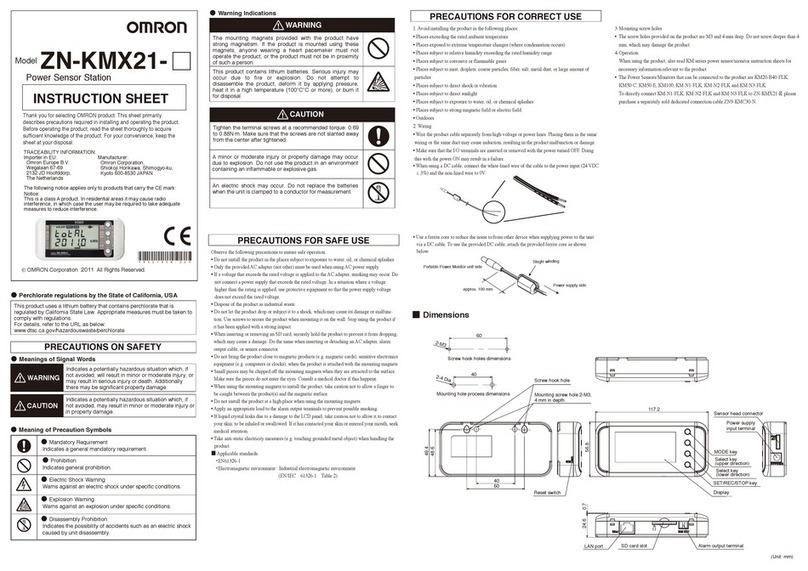

Omron ZN-KMX21 Series User manual