E3G-L1/L3 E3G-L1/L3

7

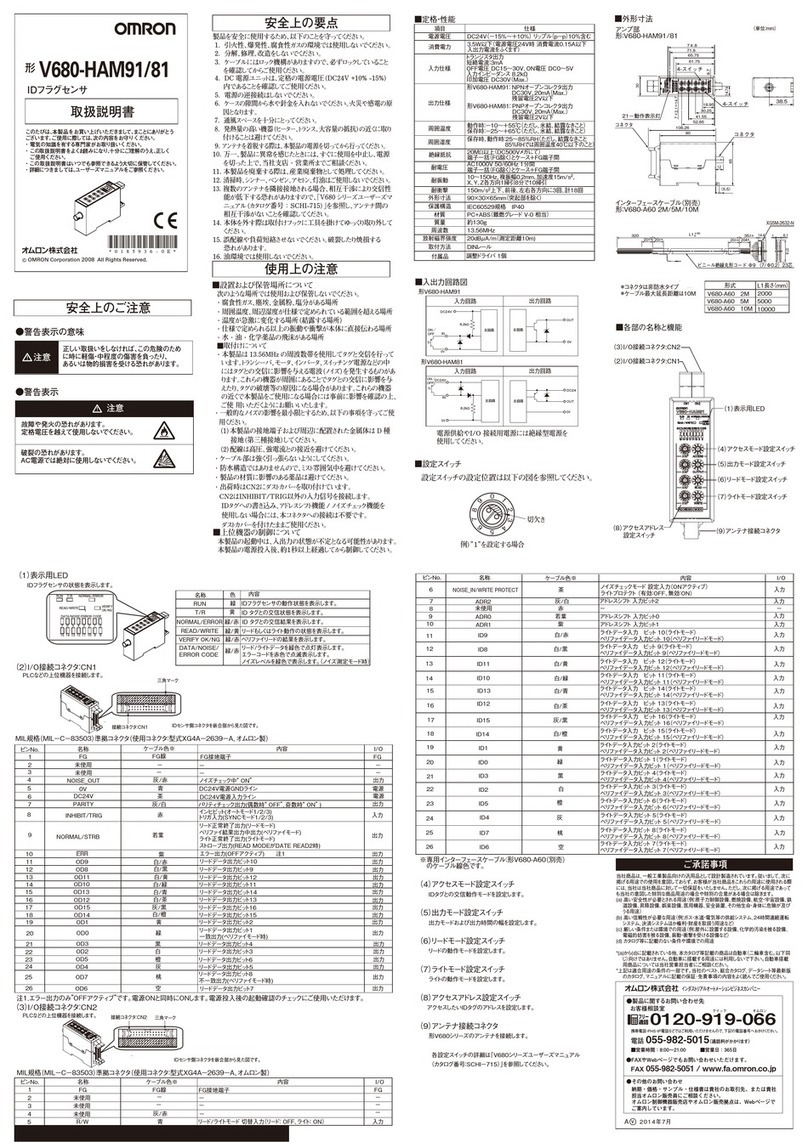

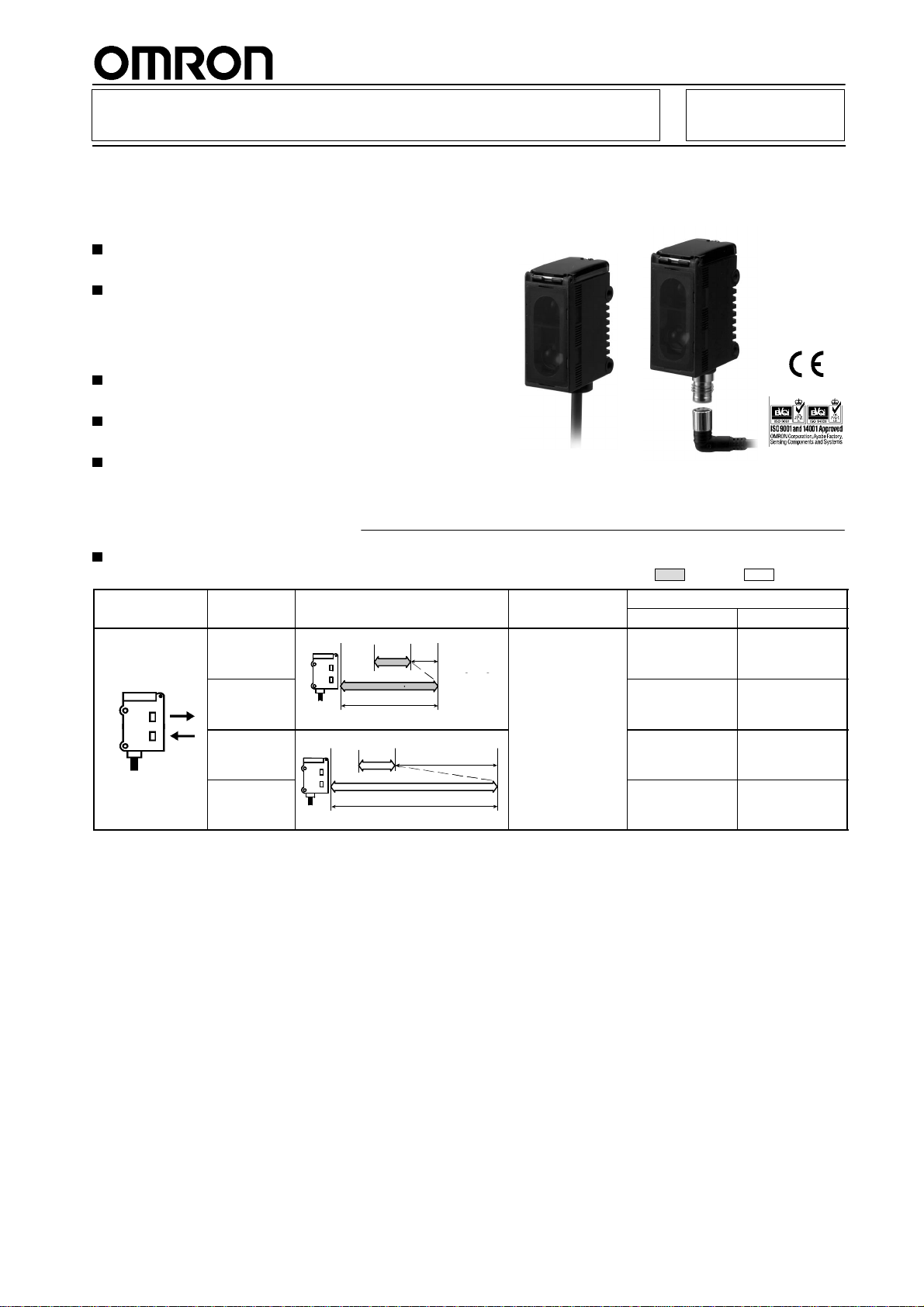

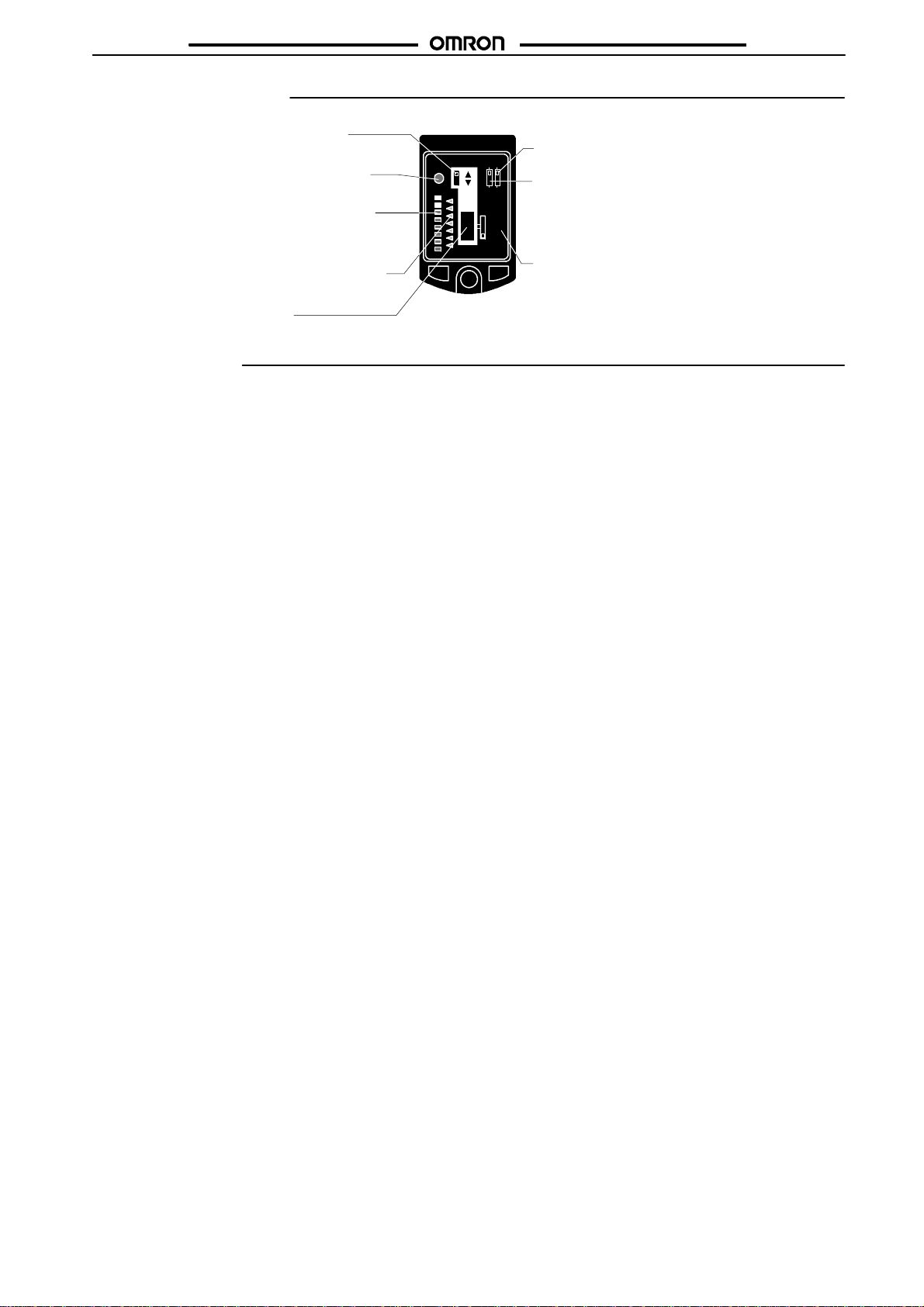

Nomenclature

UP/DOWN selector

Selects the switching direction

at threshold.

Operation indicator (Orange)

ON when output is ON.

Distance indicator (Green)

Display the distance relative to

the threshold.

Threshold indicator (Red)

Indicates threshold level.

For teaching or for threshold adjustment

Operation mode selector

Selects L-ON or D-ON.

NORMAL/ZONE selector

Selects the detection mode.

Mode selector

Selects the mode.

NORM L

ZONE D

ADJ

FAR

SET TEACH

OUT

RUN

SET button

NEAR

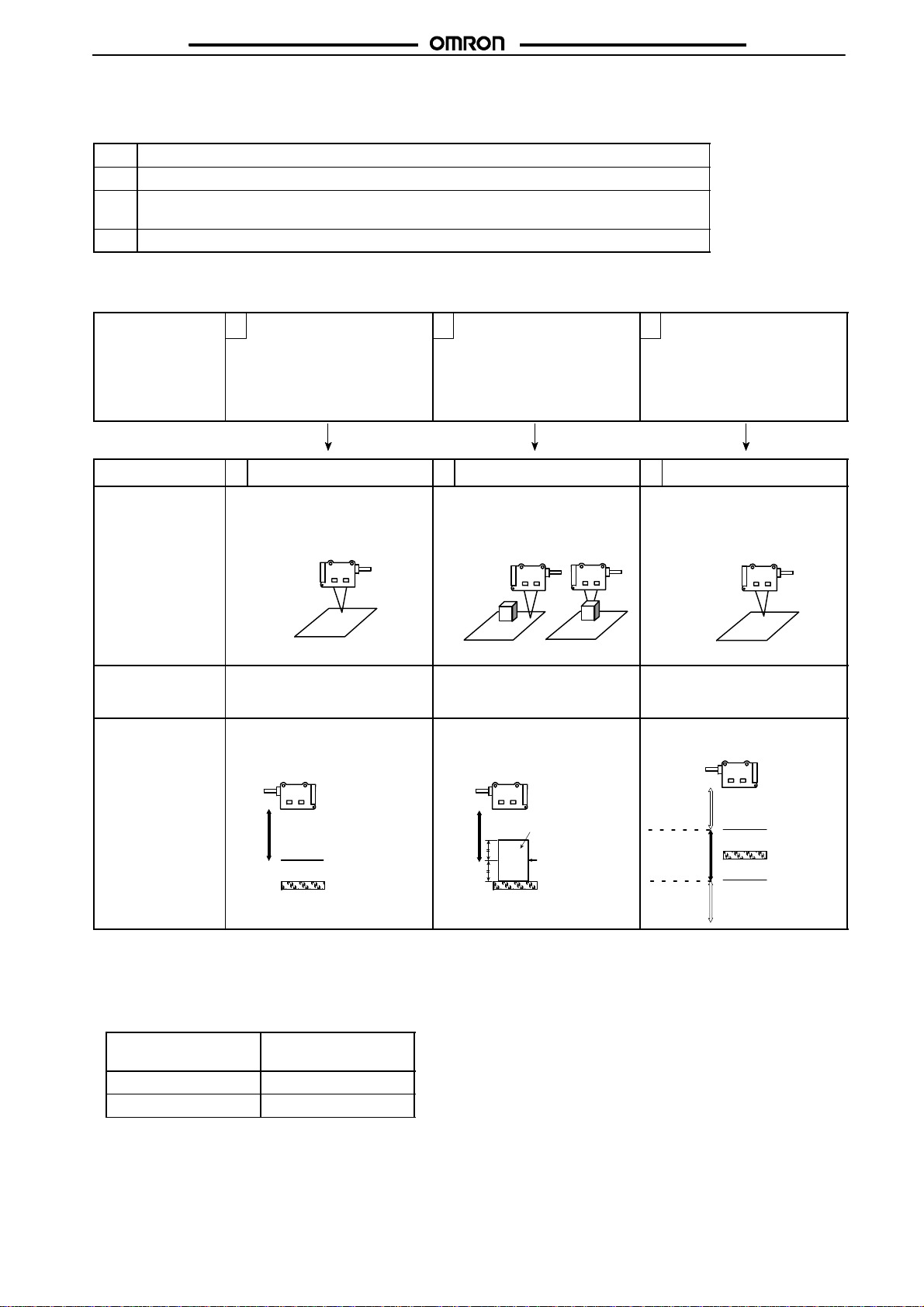

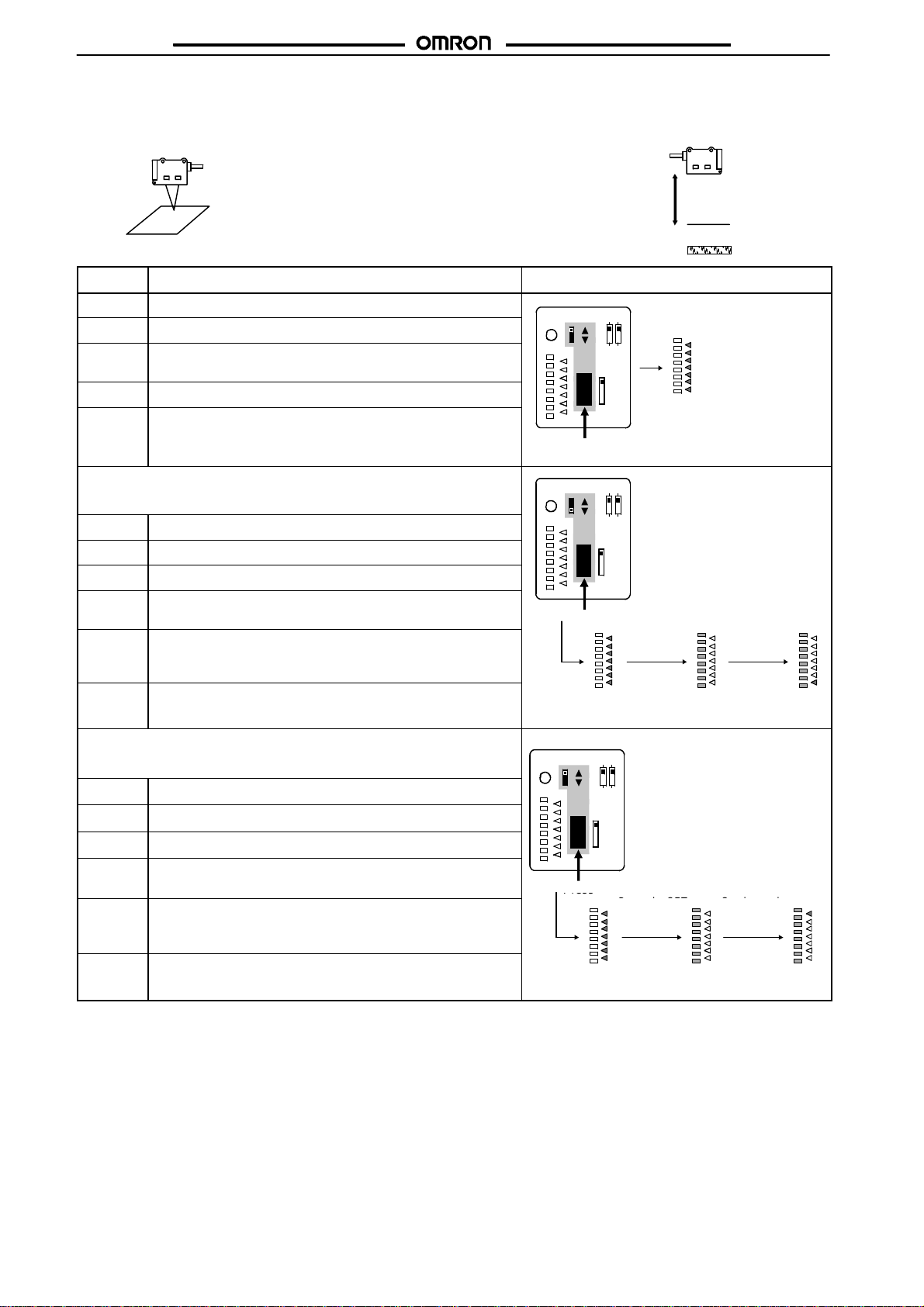

Installation

Designing

Do not pull cables with tensile strength exceeding 50 N for the

cable pull-out or connector types.

High-tension Lines

Do not wire power lines or high-tension lines alongside the lines of

the Sensor in the same conduit, otherwise the Sensor may be

damaged or may malfunction due to induction. Be sure to wire the

lines of the Sensor separated from power lines or high-tension

lines or laid in an exclusive, shielded conduit.

Turning the Power ON

The Sensor needs 100 ms to be ready to operate after it is turned

ON. The devices connected to the Photoelectric Sensor must wait

until the Sensor is ready to operate. If the Sensor and load are

connected to separate power supplies, be sure to turn ON the

Sensor first.

Power Supply

If a standard switching regulator is used, be sure to ground the FG

(frame ground) and G (ground) terminals, otherwise the Sensor

may malfunction due to the switching noise of the regulator.

Wiring

Cable

The bending radius of the cable should be 25 mm min.

In a case where the cable is extended, use a wire with 0.3 mm2

min. The total length of the cable should be 100 m max.

Avoiding Malfunctions

If using the photoelectric sensor with an inverter or servomotor, be

sure to ground the FG (frame ground) and G (ground) terminals,

otherwise the Sensor may malfunction.

Mounting

Mounting Conditions

If Sensors are mounted face-to-face, make sure that no optical

axescrosseachother. Otherwise, mutualinterferencemayresult.

Be sure toinstall the Sensor carefully so that the directional angle

range of the Sensor will not be directly exposed to intensive light,

such as sunlight, fluorescent light, or incandescent light.

Do not strike the Photoelectric Sensor with a hammer or any other

toolduringtheinstallationoftheSensor,ortheSensorwilllooseits

water-resistive properties.

Use M3 screws to mount the Sensor.

When mountingthe case, make sure that thetightening torque ap-

plied to each screw does not exceed 0.54 N m.

M8 Connector

Be sure to connect or disconnect the M8 connector after turning

OFF the Sensor.

Be sure to hold the connector cover when connecting or discon-

necting the M8 connector.

Secure the M8 connector by hand. Do not use any pliers, other-

wise the connector may be damaged.

If the M8 connector is not connected securely, the M8 connector

may be disconnected by vibration or the proper degree of protec-

tion of the Sensor may not be maintained.