INSTRUCTION SHEET

Thank you for selecting OMRON product. This sheet

primarily describes precautions required in installing and

operating the product.

Before operating the product, read the sheet thoroughly

to acquire sufficient knowledge of the product. For your

convenience, keep the sheet at your disposal.

Model

FLV-CL□

© OMRON Corporation 2013 All Rights Reserved.

PRECAUTIONS ON SAFETY

●Meanings of Signal Words

●Alert Statements in This Sheet

This product is not designed or rated for ensuring safety of

persons either directly or indirectly. Do not use it for such

purposes.

Do not disassemble the product. Doing so may cause

electric shock due to the high voltage portion. Burn also

may result due to high temperature. Do not attempt to

disassemble, deform by pressure, incinerate, repair, or

modify this product.

Indicates a potentially hazardous situation which, if not

avoided, will result in minor or moderate injury, or may

result in serious injury or death. Additionally, there may

be significant property damage.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury or in

property damage.

CAUTION

WARNING

CoaxialLighting

The following notice applies only to products that carry the CE mark:

Notice:

This is a class A product. In residential areas it may cause radio

interference, in which case the user may be required to take adequate

measures to reduce interference.

Manufacturer:

Omron Corporation,

Shiokoji Horikawa, Shimogyo-ku,

Kyoto 600-8530 JAPAN

Ayabe Factory

3-2 Narutani, Nakayama-cho,

Ayabe-shi, Kyoto 623-0105 JAPAN

TRACEABILITY INFORMATION:

Representative in EU:

Omron Europe B.V.

Wegalaan 67-69

2132 JD Hoofddorp,

The Netherlands

2280615-1D

②

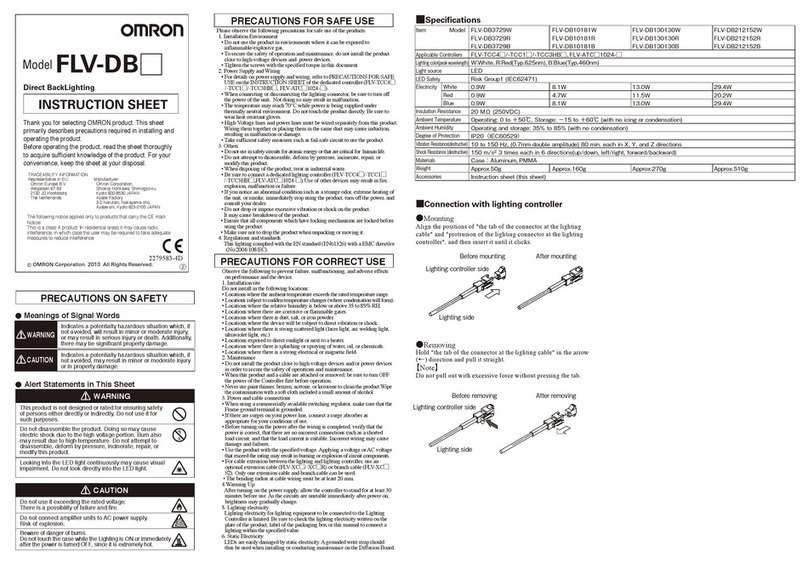

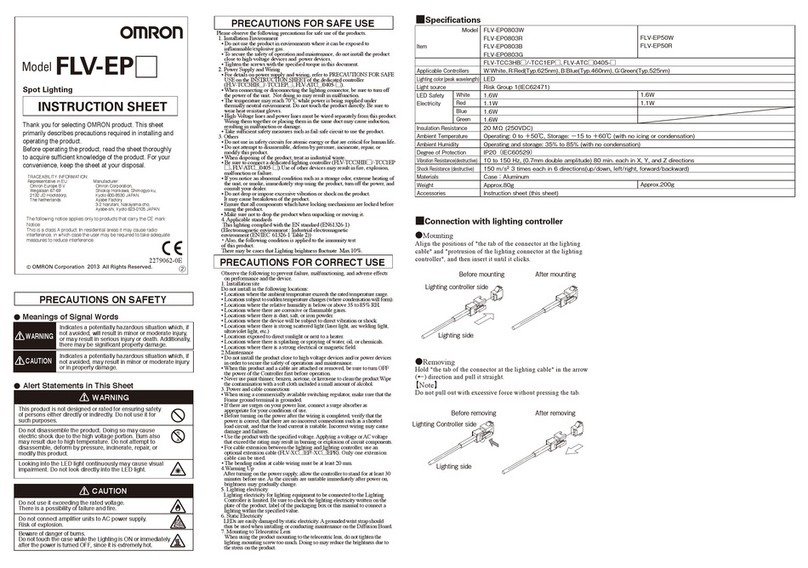

■Specifications

Item

ApplicableControllers

Lightingcolor(peakwavelength)

Lightsource

LEDSafety

Electricity

InsulationResistance

AmbientTemperature

AmbientHumidity

DegreeofProtection

VibrationResistance(destructive)

ShockResistance(destructive)

Materials

Weight

Accessories

Model

White

Red

Blue

FLV-CL30W

FLV-CL30R

FLV-CL30B

FLV-TCC4□/-TCC1□/-TCC3HB□,FLV-ATC□1024-□

W:White,R:Red(Typ.635nm),B:Blue(Typ.460nm)

LED

RiskGroup1(IEC62471)

2.4W

1.4W

2.4W

20MΩ(250VDC)

Operating:0to+50℃,Storage:−15to+60℃(withnoicingorcondensation)

Operatingandstorage:35%to85%(withnocondensation)

IP20(IEC60529)

10to150Hz,(0.7mmdoubleamplitude)80min.eachinX,Y,andZdirections

150m/s23timeseachin6directions(up/down,left/right,forward/backward)

Case:Aluminum

Approx.110g

Instructionsheet(thissheet)

FLV-CL40W

FLV-CL40R

FLV-CL40B

3.9W

2.3W

3.9W

Approx.170g

FLV-CL60W

FLV-CL60R

FLV-CL60B

10.4W

5.7W

10.4W

Approx.380g

FLV-CL80W

FLV-CL80R

FLV-CL80B

10.8W

7.2W

10.8W

Approx.580g

FLV-CL100W

FLV-CL100R

FLV-CL100B

22.7W

15.2W

22.7W

Approx.820g

Do not use it exceeding the rated voltage.

There is a possibility of failure and fire.

Do not connect amplifier units to AC power supply.

Risk of explosion.

Looking into the LED light continuously may cause visual

impairment. Do not look directly into the LED light.

CAUTION

Beware of danger of burns.

Do not touch the case while the Lighting is ON or immediately

after the power is turned OFF, since it is extremely hot.

■Connection with Lighting Controller

・Mounting

Alignthepositionsof"thetaboftheconnectoratthe

lightingcable"and"protrusionofthelightingconnectorat

theLightingController",andtheninsertituntilitclicks.

・Removing

Hold"thetaboftheconnectoratthelightingcable"inthe

arrow(←)directionandpullitstraight.

[Note]

Donotpulloutwithexcessiveforcewithoutpressingthe

tab.Doingsomaybreakthewire.

Beforemounting

LightingControllerside

Lightingcontrollerside

Lightingside

Lightingside

Aftermounting

Beforeremoving Afterremoving

Please observe the following precautions for safe use of the products.

1. Installation Environment

•Do not use the product in environments where it can be exposed to

inflammable/explosive gas.

• To secure the safety of operation and maintenance, do not install the product

close to high-voltage devices and power devices.

• Tighten the screws with the specified torque in this document.

2. Power Supply and Wiring

• For details on power supply and wiring, refer to PRECAUTIONS FOR

SAFE USE on the INSTRUCTION SHEET of the dedicated controller

(FLV-TCC4□/-TCC1□/-TCC3HB□, FLV-ATC□1024-□).

• When connecting or disconnecting the lighting connector, be sure to turn off

the power of the unit. Not doing so may result in malfunction.

• The temperature may reach 70°C while power is being supplied under

thermally neutral environment. Do not touch the product directly. Be sure to

wear heat-resistant gloves.

• High-Voltage lines and power lines must be wired separately from this

product. Wiring them together or placing them in the same duct may cause

induction, resulting in malfunction or damage.

• Take sufficient safety measures such as fail-safe circuit to use the product.

3. Others

• Do not use in safety circuits for atomic energy or that are critical for human life.

• Do not attempt to disassemble, deform by pressure, incinerate, repair, or

modify this product.

• When disposing of the product, treat as industrial waste.

• Be sure to connect a dedicated lighting controller (FLV-TCC4□/-TCC1□

/-TCC3HB□, FLV-ATC□1024-□).Use of other devices may result in fire,

explosion, malfunction or failure.

• If you notice an abnormal condition such as a strange odor, extreme heating

of the unit, or smoke, immediately stop using the product, turn off the power,

and consult your dealer.

• Do not drop or impose excessive vibration or shock on the product. It may

cause breakdown of the product.

• Ensure that all components which have locking mechanisms are locked

before using the product.

• Make sure not to drop the product when unpacking or moving it.

4. Regulations and standards

This lighting complied with the EN standard (EN61326) with a EMC

directive (No.2004/108/EC).

PRECAUTIONS FOR SAFE USE

Observe the following to prevent failure, malfunctioning, and adverse effects

on performance and the device.

1. Installation site

Do not install in the following locations:

• Locations where the ambient temperature exceeds the rated temperature range.

• Locations subject to sudden temperature changes (where condensation will form).

• Locations where the relative humidity is below or above 35 to 85% RH.

• Locations where there are corrosive or flammable gases.

• Locations where there is dust, salt, or iron powder.

• Locations where the device will be subject to direct vibration or shock.

• Locations where there is strong scattered light (laser light, arc welding light,

ultraviolet light, etc.)

• Locations exposed to direct sunlight or next to a heater.

• Locations where there is splashing or spraying of water, oil, or chemicals.

• Locations where there is a strong electrical or magnetic field.

2. Maintenance

• Do not install the product close to high-voltage devices and/or power devices

in order to secure the safety of operations and maintenance.

• When this product and a cable are attached or removed, be sure to turn OFF

the power of the Controller first before operation.

•

Never use paint thinner, benzen, acetone, or kerosene to clean the product.Wipe

the contamination with a soft cloth included a small amount of alcohol.

3. Power and cable connections

• When using a commercially available switching regulator, make sure that the

Frame ground terminal is grounded.

• If there are surges on your power line, connect a surge absorber as

appropriate for your conditions of use.

• Before turning on the power after the wiring is completed, verify that the

power is correct, that there are no incorrect connections such as a shorted

load circuit, and that the load current is suitable. Incorrect wiring may cause

damage and failures.

• Use the product with the specified voltage. Applying a voltage or AC voltage

that exceed the rating may result in burning or explosion of circuit components.

• For cable extension between the lighting and lighting controller, use an optional

extension cable (FLV-XC□/-XC□R) or branch cable (FLV-XC□S2). Only

one extension cable and branch cable can be used.

• The bending radius at cable wiring must be at least 20 mm.

• In order to radiate a heat efficiently, set up the lighting with a space more than

the heat radiation space (specified in the outline drawing) between the

lighting and other devices.

4.Warming Up

After turning on the power supply, allow the controller to stand for at least 30

minutes before use. As the circuits are unstable immediately after power on,

brightness may gradually change.

5. Lighting electricity

Lighting electricity for lighting equipment to be connected to the Lighting

Controller is limited. Be sure to check the lighting electricity written on the

plate of the product, label of the packaging box or this manual to connect a

lighting within the specified value.

6. Static Electricity

LEDs are easily damaged by static electricity. A grounded wrist strap should thus

be used when installing or conducting maintenance on the Diffusion Board.

PRECAUTIONS FOR CORRECT USE