8Switch Mode Power Supply S8JX

Safety Precautions

■Precautions for Safe Use

Mounting

Take adequate measures to ensure proper heat dissipation to

increase the long-term reliability of the Product. Be sure to allow

convection in the atmosphere around devices when mounting.

Do not use in locations where the ambient temperature exceeds the

range of the derating curve.

Use the metal plate as the mounting panel.

Improper mounting will interfere with heat dissipation and may

occasionally result in deterioration or damage of internal parts. Use

the standard mounting method only.

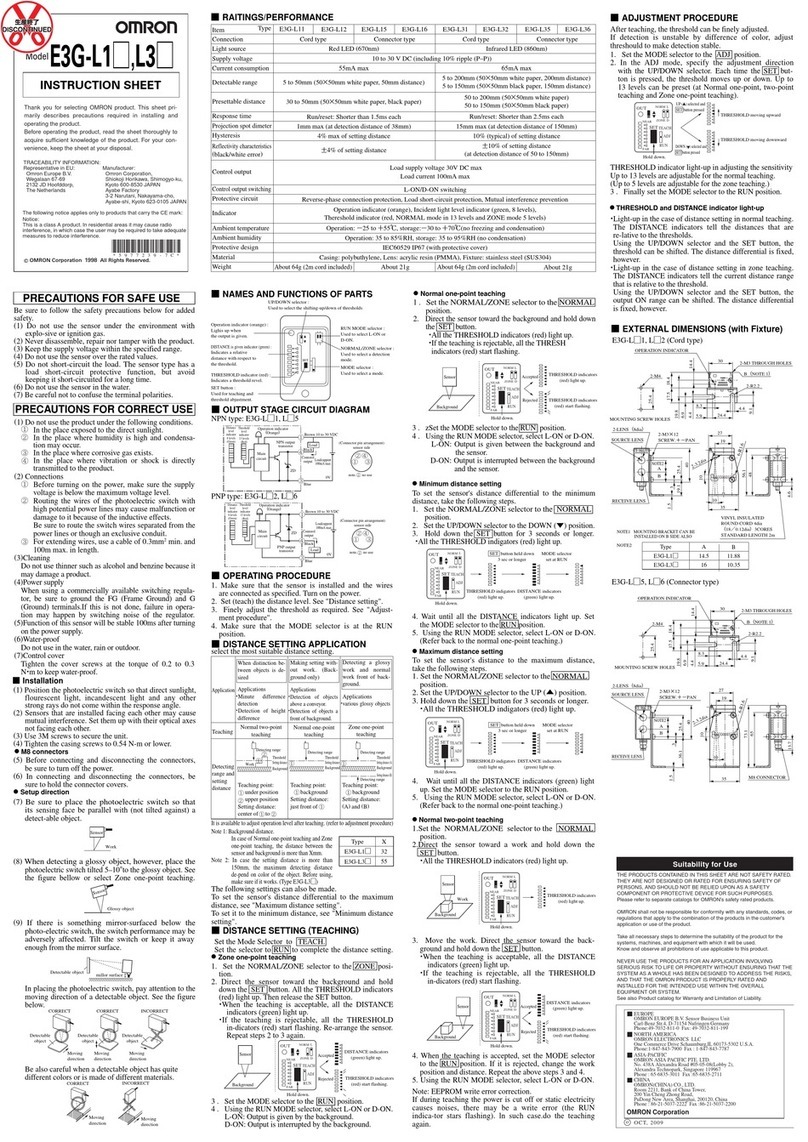

When mounting two or more Power Supplies side-by-side, allow at

least 20 mm spacing between them, as shown in the above

illustration.

Excessive insertion length may result in damage to the internal parts.

Make sure that the insertion length of mounting screws into the

Power Supply section does not exceed the specified length indicated

in the dimensions diagrams on pages 5 to 6.

When using bottom panel mounting, to ensure good heat dissipation,

some openings has to be made. However, it is advisable that the

bottom is not covered at all. When using the units’ screw hole for

mounting, do not tighten the screw more than 2.5 mm from the

surface, using 0.54 N·m torque (recommended).

Wiring

Connect the ground completely. A protective earthing terminal

stipulated in safety standards is used. Electric shock or malfunction

may occur if the ground is not connected completely.

Minor fire may possibly occur. Ensure that input and output terminals

are wired correctly.

Do not apply more than 100 N force to the terminal block when

tightening it.

Regardless of whether the Unit has a cover or not, before performing

machining above the Unit, protect the Unit with a sheet so that the

Unit will be free from such metal dust or chips.

Be sure to remove the sheet covering the Product for machining

before power-ON so that it does not interfere with heat dissipation.

Use the following material for the wires to be connected to the S8JX

to prevent smoking or ignition caused by abnormal loads.

Recommended Wire Type

Selection of Wires

Wires for the power supply should must be carefully selected. Refer

to this table when selecting the wires.

Recommended Maximum Current

The table is applicable to wires with 1 to 4 conductors. Keep the

current value to within 80% of the values shown in this table when

using wires having 5 or more conductors.

Minor electric shock, fire, or Product failure may

occasionally occur. Do not disassemble, modify, or repair

the Product to touch the interior of the Product.

Minor burns may occasionally occur. Do not touch the

Product while power is being supplied or immediately

after power is turned OFF.

Fire may occasionally occur. Tighten terminal screws to

the specified torque of 0.8 N·m.

Minor injury due to electric shock may occasionally occur.

Do not touch the terminals while power is being supplied.

Always close the terminal cover after wiring.

Minor electric shock, fire, or Product failure may

occasionally occur. Do not allow any pieces of metal or

conductors or any clippings or cuttings resulting from

installation work to enter the Product.

The residual voltage of up to 373 V generated within the

Power Supply may occasionally result in electric shock.

Do not touch the internal parts of the Power Supply within

10 seconds after turning OFF the Power Supply.

!CAUTION

20 mm (min)

75 mm (min)

75 mm (min)

Convection of air

Model Recommended wire type

S8JX-03505 AWG 16 to 14 (1.309 to 2.081 mm2)

S8JX-03512 AWG 18 to 14 (0.823 to 2.081 mm2)

S8JX-03524

S8JX-05005 AWG 14 (2.081 mm2)

S8JX-05012 AWG 18 to 14 (0.823 to 2.081 mm2)

S8JX-05024

S8JX-10024

S8JX-15024 AWG 16 to 14 (1.309 to 2.081 mm2)

AWG

No.

Cross-

sectional

area

(mm2)

Configura-

tion

(number of

conduc-

tors/mm)

Vol tag e

drop per

1 A

(mV/meter)

Recommended maximum

current (A)

UL 1007

(300 V at 80°C)

UL 1015

(600 V at 105°C)

30 0.051 7/0.102 358 0.12 ---

28 0.081 7/0.127 222 0.15 0.2

26 0.129 7/0.16 140 0.35 0.5

24 0.205 11/0.16 88.9 0.7 1.0

22 0.326 17/0.16 57.5 1.4 2.0

20 0.517 26/0.16 37.6 2.8 4.0

18 0.823 43/0.16 22.8 4.2 6.0

16 1.309 54/0.18 14.9 5.6 8.0

14 2.081 41/0.26 9.5 --- 12.0

12 3.309 65/0.26 6.0 --- 22.0

10 5.262 104/0.26 3.8 --- 35.0