General Information General Information

27

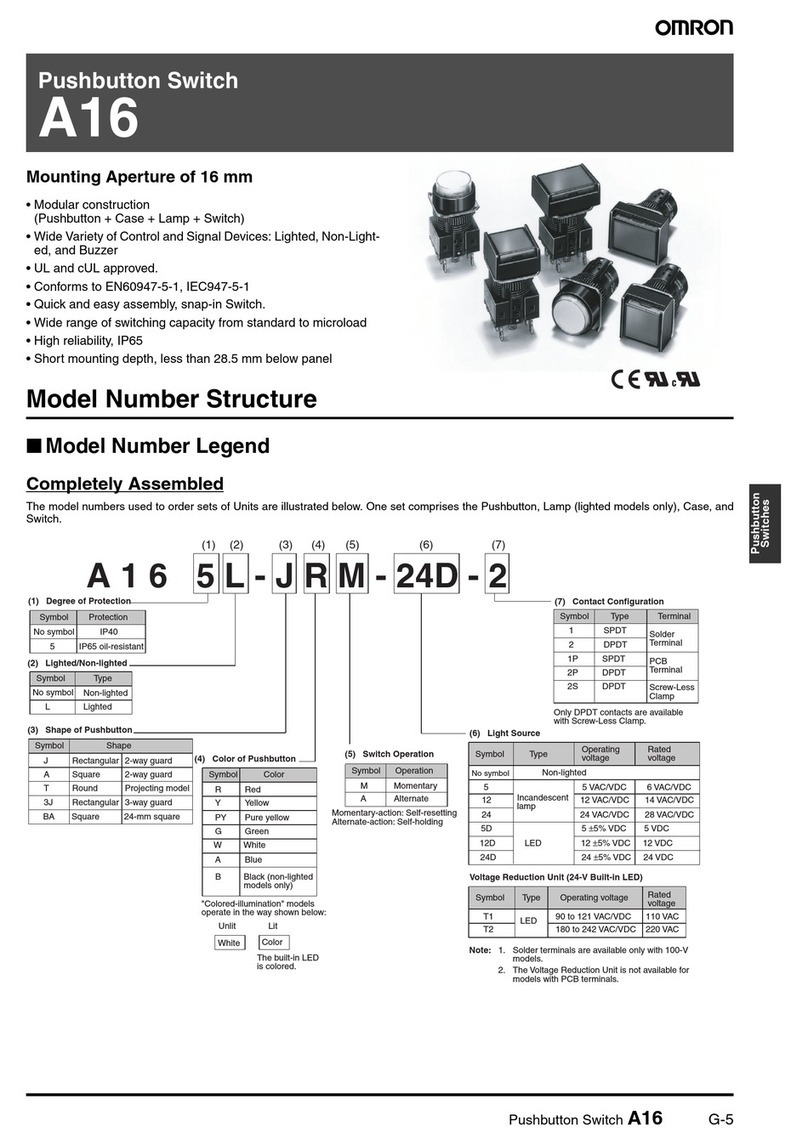

Contact Protective Circuit

Apply a contact protective circuit (surge killer) to extend contact du-

rability, prevent noise, and suppress the generation of carbide or ni-

tric acid due to arc. Be sure to apply the contact protective circuit

properly, otherwise an adverse effect may result. Some typical

examples of contact protective circuit are described in the following

table.

When a switch is used under high humidity, arcs resulting from cer-

tain types of load (e.g., inductive loads) will generate nitrious oxides

and, with mater the nitrious oxides will become nitric acid, which will

corrode internal metal parts and may cause malfunctions. Always

use a contact protective circuit according to information provided in

the following table when using a switch under circuit conditions of

frequent switching and arcing.

The use of a contact protective circuit may delay the response time

of the load.

Typical Examples of Contact Protective Circuits (Surge Killers)

Circuit example Applicable

current Feature Element selection

AC DC

CR

circuit

Power

supply

Inductive

load

See

note. Yes Note: When AC is switched, the

load impedance must be low-

er than the C and R imped-

ance.

C: 0.5 to 1 µF per switching current (1 A)

R: 0.5 to 1 Ωper switching voltage (1 V)

The values may change according to the

characteristics of the load.

The capacitor suppresses the spark

discharge of current when the contacts are

open. The resistor limits the inrush current

when the contacts are closed again.

Consider these roles of the capacitor and

resistor and determine the ideal

Inductive

load

Power supply

Yes Yes The operating time will increase if the

load is a relay or solenoid.

It is effective to connect the CR circuit

in parallel to the load when the power

supply voltage is 24 or 48 V and in

parallel to the contacts when the

power supply voltage is 100 to 200 V.

capacitance and resistance values from

experimentation.

Use a capacitor with a dielectric strength

between 200 and 300 V. When AC is

switched, make sure that the capacitor has

no polarity.

If, however, the ability to control arcs

between contacts is a problem for high DC

voltage, it may be more effective to

connect a capacitor and resistor between

the contacts across the load. Check the

results by testing in the actual application.

Diode

method

Power supply

Inductive

load

No Yes Energy stored in the coil is changed

into current by the diode connected in

parallel to the load. Then the current

flowing to the coil is consumed and

Joule heat is generated by the

resistance of the inductive load. The

reset time delay in this method is

longer than that of the CR method.

The diode must withstand a peak inverse

voltage 10 times higher than the circuit

voltage and a forward current as high as or

higher than the load current.

Diode

and

Zener

diode

method

Power supply

Inductive

load

No Yes This method will be effective if the

reset time delay caused by the diode

method is too long.

Zener voltage for a Zener diode must be

about 1.2 times higher than the power

source since the load may not work under

some circumstances.

Varistor

method

Power supply

Inductive

load

Yes Yes This method makes use of

constant-voltage characteristic of the

varistor so that no high-voltage is

imposed on the contacts. This method

causes a reset time delay more or

less. It is effective to connect varistor

in parallel to the load when the supply

voltage is 24 to 48 V and in parallel to

the contacts when the supply voltage

is 100 to 200 V.

Select the varistor so that the following

condition is met for the cut voltage Vc. For

AC currents, the value must be multiplied

by √2.

Vc > (Current Voltage x 1.5)

If Vc is set too high, however, the voltage

cut for high voltages will no longer be

effective, diminishing the effect.

Do not apply contact protective circuit as shown below.

This circuit effectively suppresses arcs when

the contacts are OFF. The capacitance will be

charged, however, when the contacts are OFF.

Consequently, when the contacts are ON again,

short-circuited current from the capacitance

may cause contact weld.

Load

Power

supply

Incorrect This circuit effectively suppresses

arcs when the contacts are OFF.

When the contacts are ON again,

however, charge current flows to

the capacitor, which may result in

contact weld.

Load

Power

supply

Incorrect