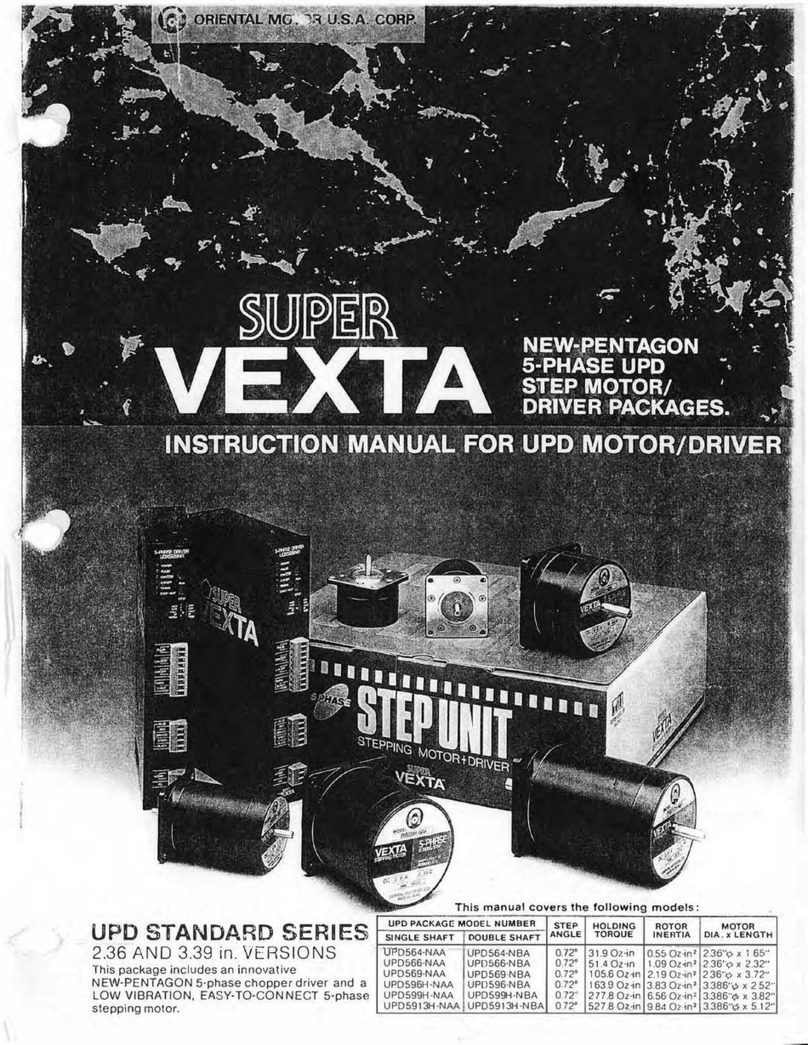

Installing gearmotor

Motor

Gearhead

Screws for mounting

provided with gearhead

Mounting

Plate

Washers

Nuts

Use the mounting screws provided with the gearhead to mount the gearhead and

motor on equipment.

• Decimal gearhead

Motor

Decimal gearhead

Gearhead

Washers

Nuts

Screws for mounting

provided with decimal gearhead

Mounting

Plate

Use the screws provided with the decimal gearhead and secure all parts so that

there are no gaps between the motor flange face and the recessed area of the

decimal gearhead and between the decimal gearhead and the gearhead's recessed

area.

∗ Dedicated mounting brackets can also be used for installing gearmotor.

For details, please refer to catalogue.

∗ Refer Table 2 for the size of installation hole.

Attaching load

The shaft of the gearhead has been machined to an outer diameter tolerance of h7

and is provided with a key slot for connecting the transmission parts. (Model 0GN

to 5GN type have a flat on the shaft.)

When connecting the transmission parts, ensure that the shaft and parts have a

clearance fit, and secure with a screw to prevent the parts from wobbling.

Use a screw hole (No.10-24UNC, effective depth 0.39 in.) provided at the tip of

the output shaft of 5GESA as an auxiliary means for preventing the transfer

mechanism from disengaging.

< The example of output axis

tip screw hole use >

Motor Gearhead

Key

Fixed screw

Transmission parts

Fixed screw

Screw

Spacer

Transmission parts

Note Do not use excessive force, or hammer the

transmission parts onto the gearmotor shaft

as damage may occur.

Precautions for operation

• Use your gearmotor under ambient temperature of +14 to +122 °F and 85%

humidity.

• Do not use your gearmotor where it may be exposed direct sunlight water

and/or oil.

• Do not use your gearmotor in locations subject to severe vibration or shock, a

large amount of dust, inflammable gas and or corrosive gas.

• On rare occasions, a small amount of grease may ooze out from the gearhead. If

there is concern over possible environmental damage resulting from the leakage of

grease, check for grease stains during regular inspections. Alternatively, install an

oil pan or other device to prevent leakage from causing further damage. Oil

leakage may lead to problems in the customer’s equipment or products.

• Direction of rotation of the gearhead output shaft

With some gear ratios, the motor and gearhead output shaft will rotates in opposite

directions. The direction of rotation does not change if a decimal gearhead is

connected.

Gear ratio

Gearhead model name Same direction as motor Opposite direction

to motor

3to 182GNSA 3GNSA

4GNSA 5GNSA 50 to 180 25 to 36

3to 912.5 to 180GNKA 5GESA

5GUKA 25 to 60 75 to 180

∗ The square box in the gearhead model will contain a value representing the

gear ratio.

• Maximum permissible torque

Since the output torque of the gearhead increases proportionally with the reduction

of speed, a high reduction ratio of the gearhead will result in an output torque that

cannot be taken up by the physical construction of the gearhead. Use gearheads

within the maximum permissible torque set for each speed reduction ratio. For the

values of the maximum permissible torque, please refer to catalogue. Also, be sure

shaft rotation is not stopped by an external force or load obstruction. The resulting

shock may damage the gearhead.

• Permissible overhung load and permissible thrust load

“Overhung load” refers to load placed on the output

shaft of the gearhead in a direction perpendicular to

the shaft as shown to the right. The “Thrust load” is a

load applied in the axial direction of the output shaft.

Since the overhung load and thrust load have a great

influence on the life of the bearings and strength of the

shaft, be careful not to exceed the maximum values

shown in the Table 3.

Gearhead

Overhung load

Thrust load

Table 3. Permissible overhung load and permissible thrust load

Permissible

overhung load (lb.)

Output axis tip

Gearhead

model

name

Gear

ratio

Maximum

permissible

torque

(lb-in) 0.39 in. 0.79 in.

Permissible

thrust load

(lb.)

0GNKA 3 to 180 8.8 4.5

-

3.3

3to 18 11.2 18

2GNSA 25 to 180 26 27 40 6.7

3to 18 18 27

3GNSA 25 to 180 44 33 56 9

3to 18 22 33

4GNSA 25 to 180 70 45 67 11.2

3to 18 56 78

5GNSA 25 to 180 88 67 101 22

3to 990 112

12.5 to 18 101 135

5GESA

5GUKA 25 to 180

177

112 157

33

∗ The square box in the gearhead model will contain a value representing the

gear ratio.

• Unauthorized reproduction or copying of all or part of this Operating Manual

is prohibited.

• Oriental Motor shall not be liable whatsoever for any patent-related problem

arising in connection with the use of any information, circuit, equipment or

device described in the manual.

• Characteristics, specifications and dimensions are subject to change without

notice.

• While we make every effort to offer accurate information in the manual, we

welcome your input. Should you find unclear descriptions, errors or

omissions, please contact the nearest office.

• is a trademark of Oriental Motor Co., Ltd.

© Copyright ORIENTAL MOTOR CO., LTD. 2006

• Please contact your nearest Oriental Motor office for further information.

ORIENTAL MOTOR U.S.A. CORP.

Technical Support Line Tel:(800)468-3982

vailable from 7:30 AM to 5:00 PM, P.S.T.

E-mail: techsupport@orientalmotor.com

www.orientalmotor.com

ORIENTAL MOTOR CO., LTD.

Headquarters Tokyo, Japan

Tel:(03)3835-0684 Fax:(03)3835-1890 Printed on Recycled Pape