8

Digital Pressure Sensor DP-0 SERIES

PRECAUTIONS FOR PROPER USE

• Never use this product as a sensing device

for personnel protection.

• In case of using sensing devices for

personnel protection, use products which

meet laws and standards, such as OSHA,

ANSI or IEC etc., for personnel protection

applicable in each region or country.

• This product is used for non-corrosive gas.

The product shall not be used for liquid

or corrosive gas. Never use uids having

inammability, toxicity, etc., that affect the

human body, either.

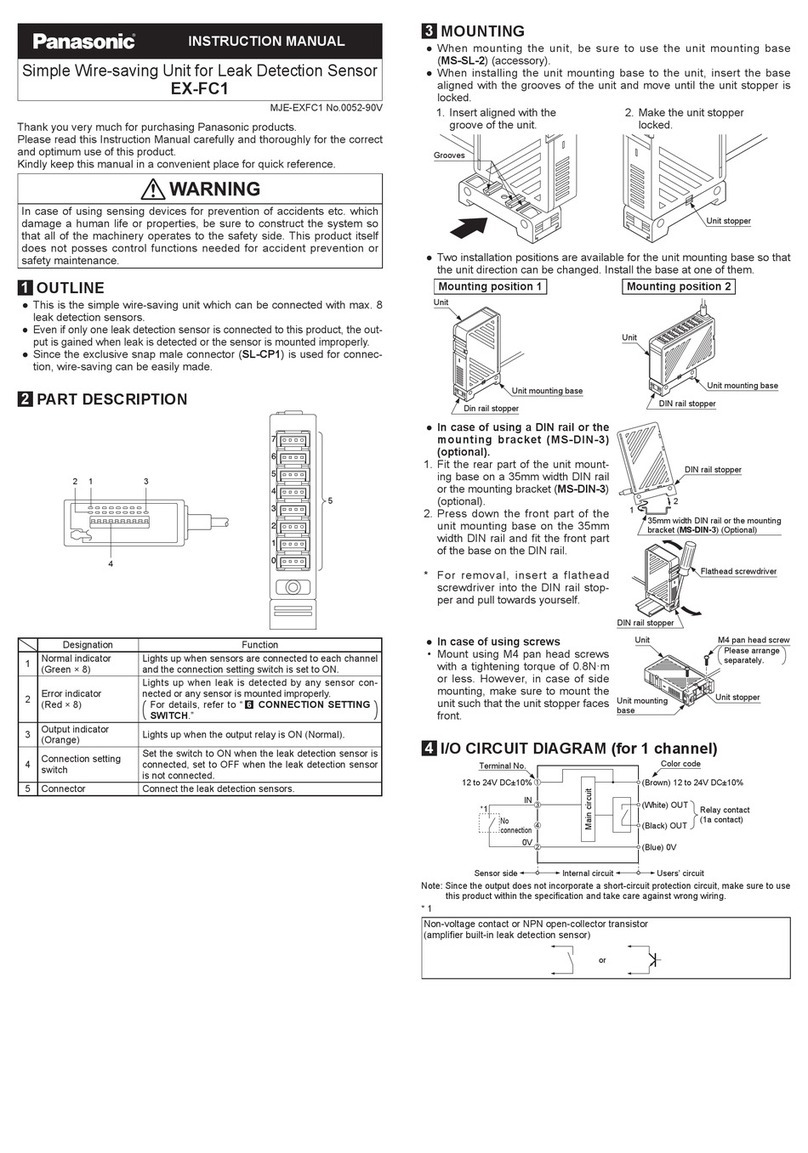

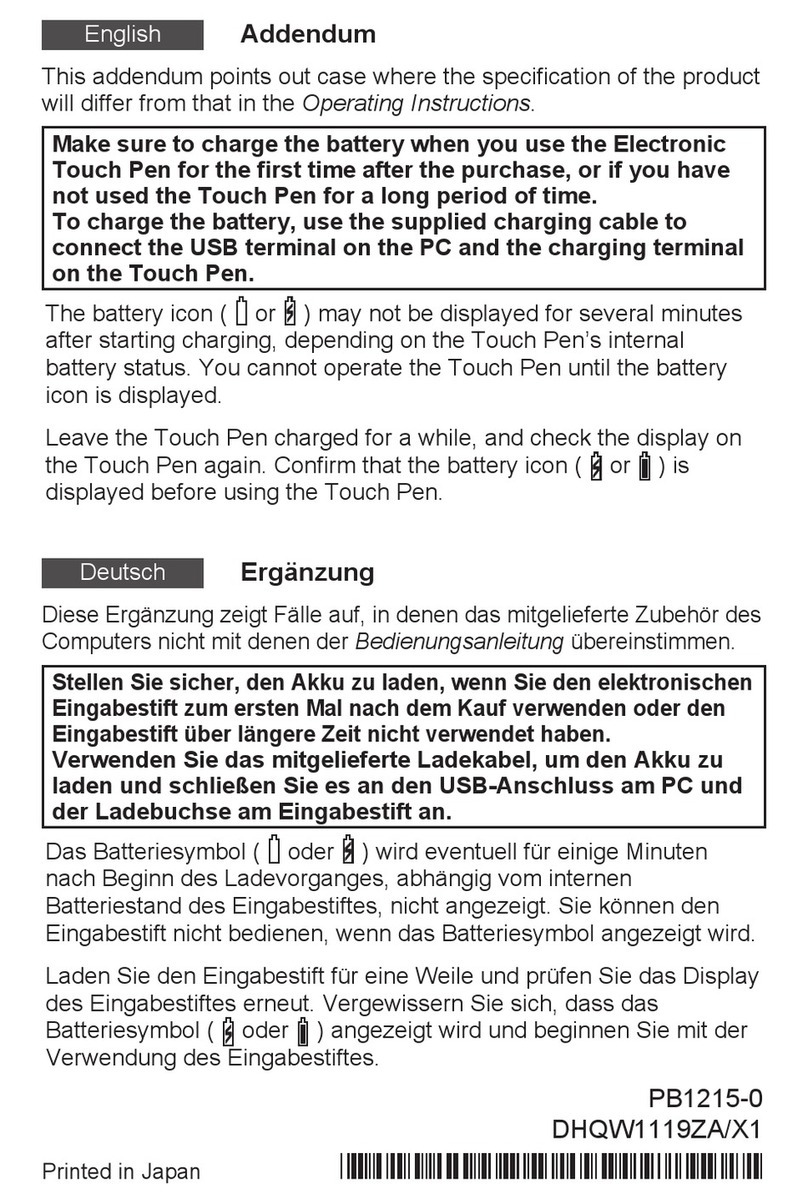

Part description

Connecting

connector

Pressure port

Mode

selection key

Digital display unit

Setting value DOWN key

Setting value UP key

OVER mark

OFF mark

ON mark

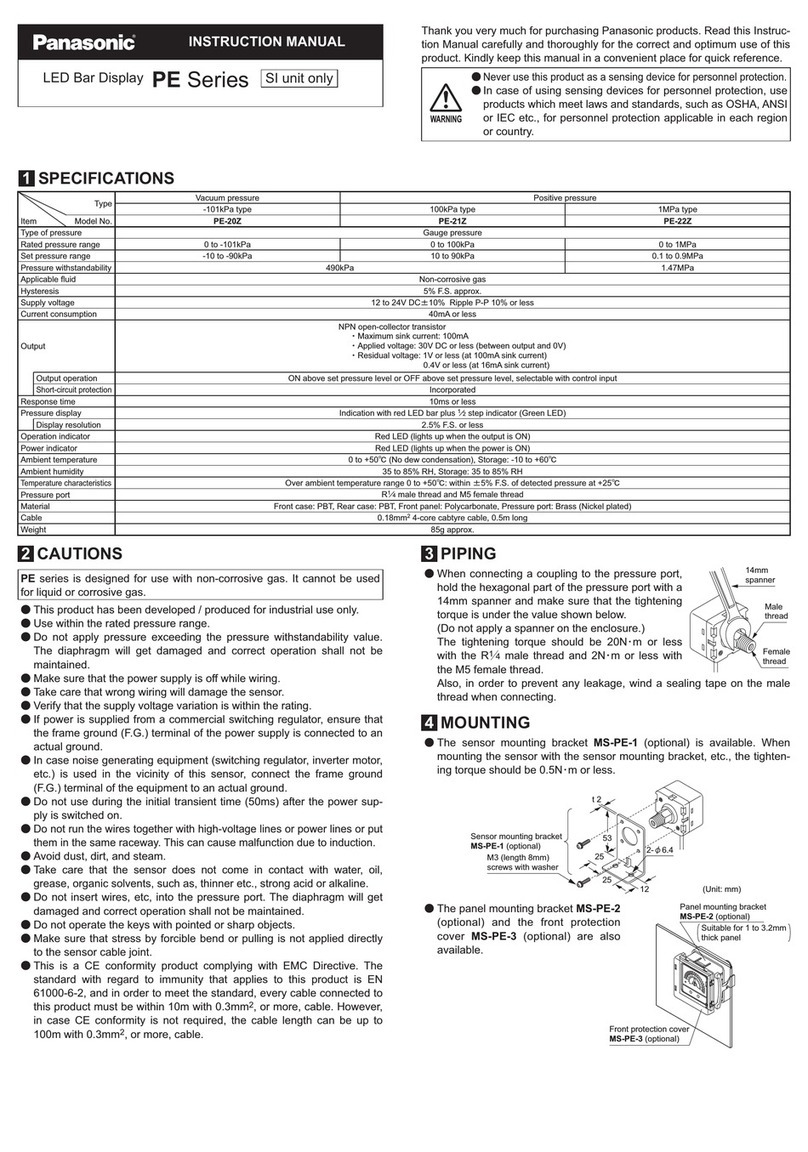

Piping

• When using this product, connect a joint available in the market

to the pressure port. At the time, the tightening torque should be

1.0 N·m or less.

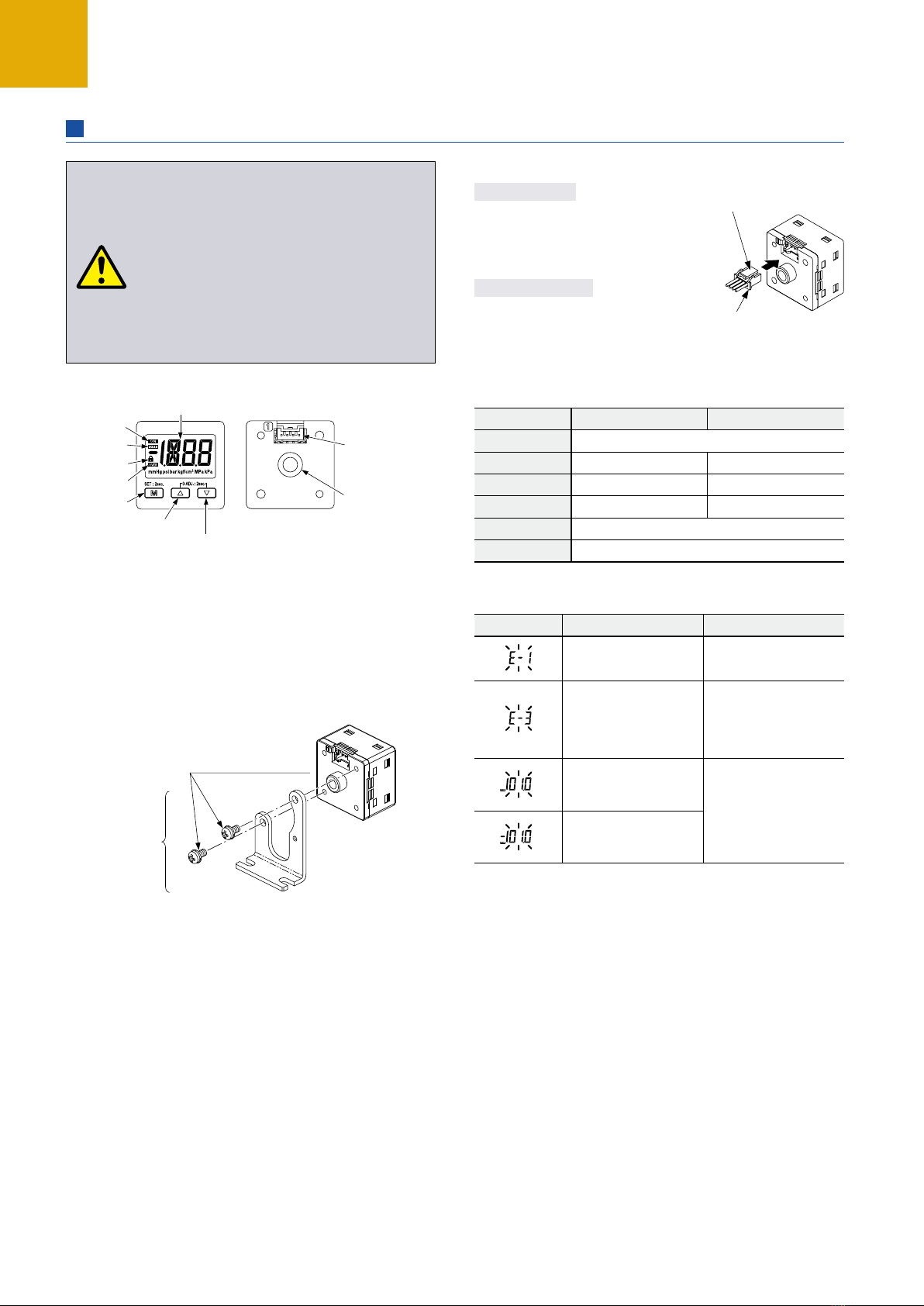

Mounting

• Use sensor mounting bracket MS-DP1-1 prepared

independently.

When mounting this product with sensor mounting bracket, etc.,

the tightening torque should be 0.5 N·m or less.

M3 (length 6 mm 0.236 in)

screws with washers

(Accessory with MS-DP1-1)

MS-DP1-1

• Panel mounting bracket MS-DP1-8 (optional) and front protection

cover MS-DP1-3 (optional) are available.

• For the method for mounting panel mounting bracket, refer to the

instruction manual that came with the MS-DP1-8.

Wiring

• Make sure that the power supply is OFF while performing the

wiring operation.

• Verify that the supply voltage variation is within the rating.

• If power is supplied from a commercial switching regulator,

ensure that the frame ground (F.G.) terminal of the power supply

is connected to an actual ground.

• In case noise generating equipment (switching regulator, inverter

motor, etc.) is used in the vicinity of this product, connect the

frame ground (F.G.) terminal of the equipment to an actual

ground.

• When extending the cable, use a cable whose conductor cross-

section area is 0.3 mm2 or more. The cable can be extended to

up to 10 m 32.808 ft in total length.

• Do not run the wires together with high-voltage lines or power

lines or put them in the same raceway. This can cause

malfunction due to induction.

• Do not apply stress directly to the connection cable leader or to

the connector.

Connection

How to connect

• Insert the cable with connector

CN-14A(-R)‑C□ into this product’s

connection connector section as shown

in the right gure.

How to disconnect

• Pressing the release lever of the cable

with connector, pull out the connector.

Note: Do not pull by holding the cable without pressing the release lever, as

this can cause cable break or connector break.

Factory setting

Type Low pressure type High pressure type

Operation setting EASY mode

NO/NC setting NC NO

Threshold value −50.0 0.500

Pressure unit kPa MPa

Display color Red when ON, White when OFF

Response speed 2.5 ms

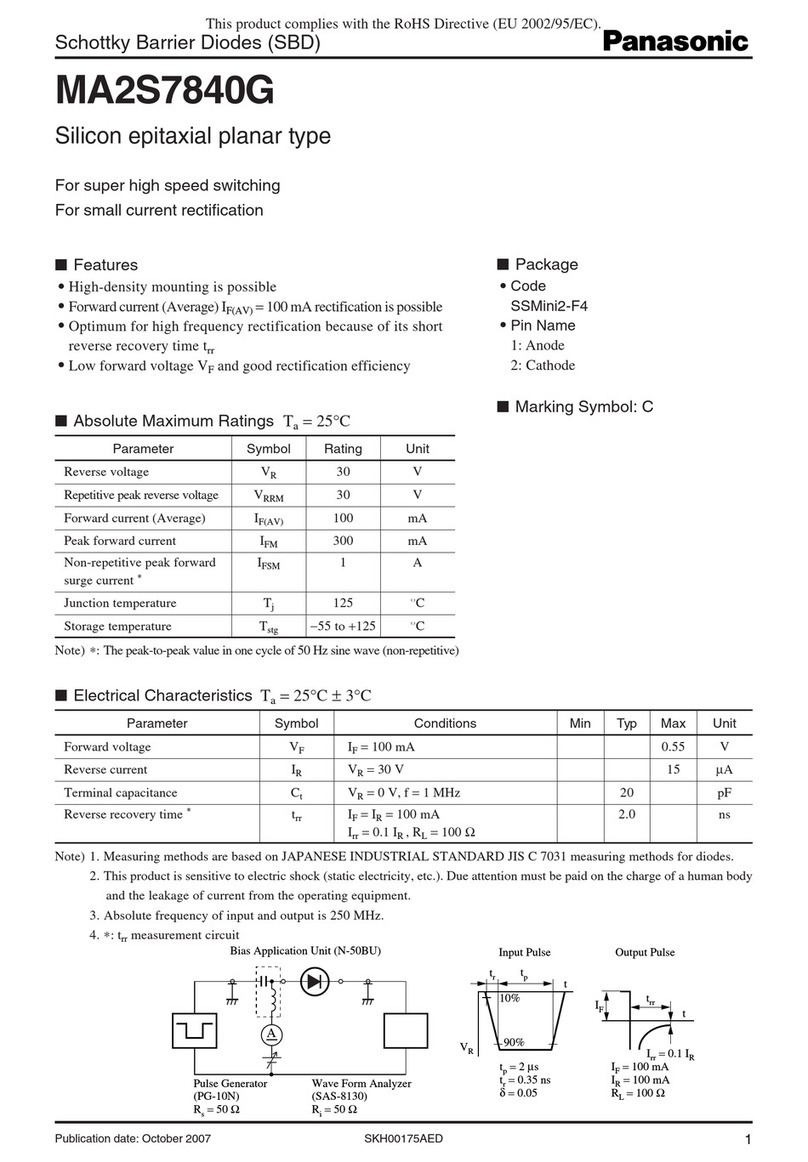

Error indication

Error indication

Description Remedy

The load is short-circuited

causing an overcurrent to

ow.

Turn OFF the power and

check the load.

Pressure is applied during

zero point adjustment.

Applied pressure at the

pressure port should be

brought to atmospheric

pressure and zero-point

adjustment should be done

again.

The applied pressure

exceeds the upper limit of

the displayed pressure

range. Applied pressure range

should be brought within

the rated pressure range.

The applied pressure

exceeds the lower limit

(back pressure) of the

displayed pressure range.

When other error massage is displayed, contact us.

Others

• This product has been developed / produced for industrial use

only.

• The product shall be used only within the rated pressure range.

• Do not apply pressure exceeding the pressure resistance.

Otherwise, destruction of diaphragm occurs, preventing the

product to perform normal operation.

• Do not use during the initial transient time (0.5 sec.) after the

power supply is switched ON.

• The specication may not be satised in a strong magnetic eld.

• This product is suitable for indoor use only.

• Take care that strong impact such as fall is not given to this

product. Otherwise, it may be destroyed.

• Avoid dust, dirt, and steam.

• Take care that the product does not come into contact with

organic solvents such as thinner.

• Take care that the product does not come into contact with oil or

grease.

• Take care that the product does not come into contact with

strong acid or alkaline.

• Do not insert wire into the pressure port. Otherwise, destruction

of diaphragm occurs, preventing the product to perform normal

operation.

Cable with connector

(

)