Panasonic Industry Co., Ltd. 9

SPECIFICATIONS

Type NPN output type PNP output type

Item Model No. HG-F13A-A-N HG-F13A-A-P

Applicable regulations and

certications

CE Marking (EMC Directive, RoHS Directive), UKCA Marking (EMC Regulations, RoHS Regulations),

FDARegulations,TÜVSÜDNRTLcertication(USA,Canada)

Measurable range 250 to 3,000 mm 9.843 in to 118.110 in

Displayable range (Note 2) 200 to 3,300 mm 7.874 in to 129.921 in

Repeatability ±10 mm 0.394 in or less

Hysteresis 30 mm 1.181 in (default setting) Possible to vary up to 1 mm 0.039 in minimum in the PRO mode (Note 3)

Linearity ± 2% F.S. (Note 4) (at a measuring distance of 500 mm to 3,000 mm 19.685 in to 118.110 in)

Temperature characteristics 0.1%F.S./°C

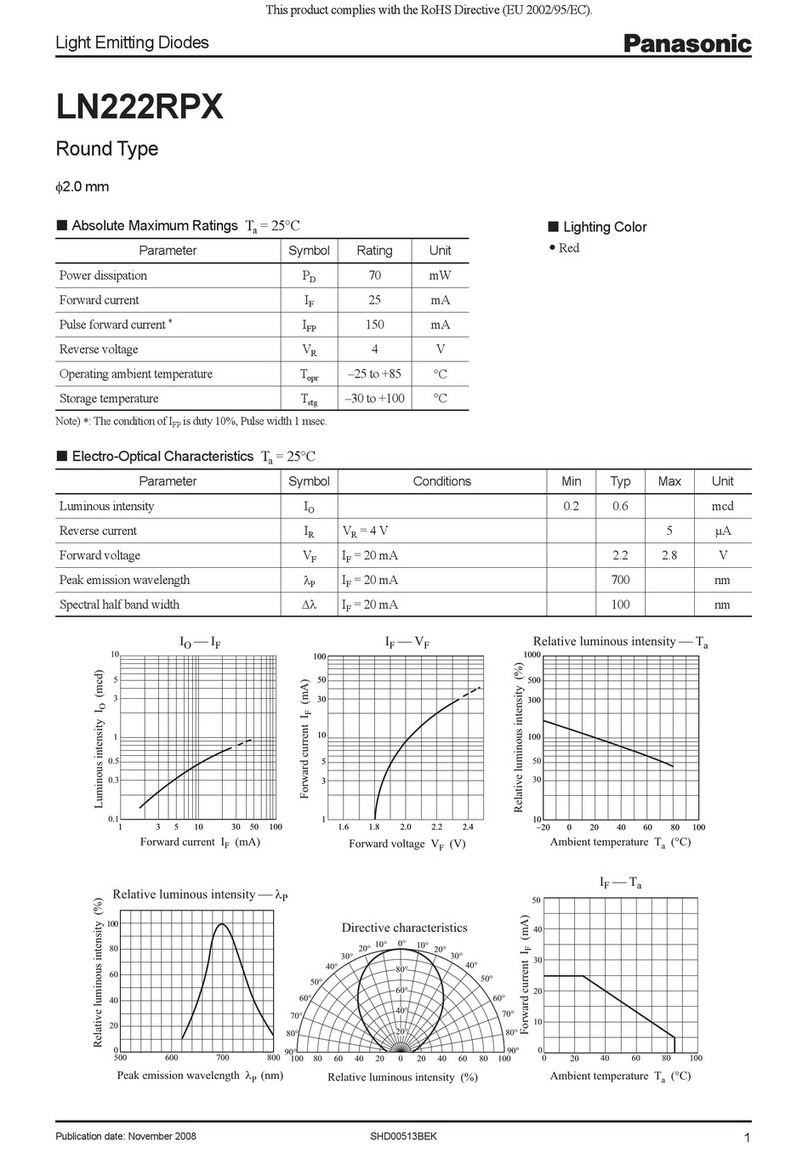

Light source Redsemiconductorlaser:Class1[JIS/IEC/GB/KS/FDA(Note5)]

Maximum output: 0.39 mW, Peak emission wavelength: 680 nm 0.0268 mil

Beam diameter (Note 6) Approx. ø10 mm ø0.394 in (typical) (at the measuring distance of 1,000 mm 39.370 in)

Supply voltage 24 V DC ±10%, Ripple P-P 10%

Power consumption (Note 7) 40 mA or less (at 24 V DC supply voltage)

Control output

NPN open-collector transistor

• Maximum sink current: 50 mA

•

Applied voltage: 30 V DC or less (Between control output to 0 V)

• Residual voltage: 1.5 V or less (At 50 mA sink current)

• Leakage current: 0.1 mA or less

PNP open-collector transistor

• Maximum source current: 50 mA

•

Applied voltage: 30 V DC or less (Between control output to +V)

• Residual voltage: 1.5 V or less (At 50 mA source current)

• Leakage current: 0.1 mA or less

Output

operation SwitchablebetweenLight-ON/Dark-ON,(Default:Light-ON)

Short-circuit

protection Incorporated (Auto reset type)

Analog output Switchablebetweenvoltageoutput/currentoutput(Default:voltageoutput)

Analog

voltage

output

Output range • In normal operation: 0 to +5 V Possible to set the distance range (Default: 250 to 3,000 mm 9.843 in to 118.110 in)

• When alarm occurs: Last value is held or the range is set to 0 V on the near point side and to +5.2 V on the far point side.

Output

impedance 100Ω

Analog

current

output

Output range • In normal operation: +4 to +20 mA Possible to set the distance range (Default: 250 to 3,000 mm 9.843 in to 118.110 in)

• When alarm occurs: Last value is held or the range is set to 0 mA on the near point side and to +20.8 mA on the far point side.

Output

impedance 250Ωorless

Response time Switchablebetween35ms/100ms/300ms/2,000ms(Default:100ms)

External input

NPN non-contact input

• Input condition

Invalid: +8 to + V DC or Open

Valid: 0 to +1.2 V DC

• Inputimpedance:approx.10kΩ

PNP non-contact input

• Input condition

Invalid: 0 to +0.6 V DC or Open

Valid: +4 to +V DC

• Inputimpedance:approx.10kΩ

External input function Switchable between zero set, teaching, or emission stop (Default: zero set)

Teaching function Switchablebetweennormalsensingmode(2-point/limit)orwindowcomparatormode(1-point/2-point/3-point)

(Default: Normal sensing mode)

Timer function SwitchablebetweenOFF/ONdelay/OFFdelay/one-shot(Default:OFF)

Timer period Switchablebetween5ms/10ms/25ms/50ms/100ms/250ms/500ms/1,000ms/5,000ms(Default:5ms)

Pollution degree 2

Overvoltage category Category I

Ambient altitude (Note 8) 2,000 m 6561.680 ft or less

Environmental

resistance

Protection IP67 (IEC)

Ambient temperature -10to+45°C+14to113°F(Nodewcondensationoricingallowed),Storage:-20to+60°C-4to140°F

Ambient humidity 35 to 85% RH, Storage: 35 to 85% RH

Ambient illuminance Incandescentlight:3,000ℓxorlessatthelight-receivingface

Vibration resistance 10 to 55 Hz (period: 1 min.) frequency, 1.5 mm 0.059 in double amplitude in X, Y and Z directions for two hours each

Shock resistance 500m/s2acceleration(approx.50G)inX,YandZdirectionsthreetimeseach

Cable 0.2 mm25-core composite cable, 2 m 6.562 ft long

Cable extension Extension up to total 10 m 32.808 ft is possible with 0.3 mm2, or more, cable

Material Enclosure: Aluminum die-cast, Front cover: Acrylic, Cable: PVC

Weight Netweight:approx.85g,Grossweight:approx.130g

Notes:1)Unlessotherwisespecied,measurementconditionsareasfollows:Powersupplyvoltageof24VDC,ambienttemperatureof+20°C+68°F, response

time of 100 ms, and measuring distance of 1,000 mm 39.370 in. The target object is a 200 mm × 200 mm 7.874 in ×7.874 in white non-glossy paper.

Perform measurement 30 minutes after turning on the power supply.

2) When an object is detected, the range of numerical values that appear on the digital display is regarded as the displayable distance. When zero setting

is performed, the displayable distance varies depending on the zero setting distance.

3) Changing the hysteresis may result in unstable sensing. After making a change, perform operation check using actual equipment.

4) F.S. (full scale) represents a range from 0 mm to 3,000 mm 0 in to 118.110 in.

5) This product complies with the FDA regulations (FDA 21 CFR 1040.10 and 1040.11) in accordance with FDA Laser Notice No. 56, except for complying

with IEC 60825-1 Ed. 3.

6)Thebeamdiameterisdenedas1/e2(approx.13.5%)ofthecenterlightintensity.Duetoleaklightoutsidethedenedrange,themeasurementvalues

maybeaectedifthereectancearoundthedetectingpointishigherthanthatofthedetectingpoint.

7) Analog output is not included.

8) Do not use or store this product in environments where ambient air is pressurized to an air pressure higher than the atmospheric pressure at an altitude

of 0 m.