Procedure

Sensing output

setting

External input

setting

Measurement display

DOWN: Press for 3 seconds

UP / DOWN

UP / DOWN

UP / DOWN

UP / DOWN

UP / DOWN

UP / DOWN

UP / DOWN

UP / DOWN

UP / DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

TEACH

TEACH

TEACH

TEACH

TEACH

TEACH

TEACH

TEACH

TEACH

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

UP /

DOWN

Response time

setting

Response time

setting

Timer setting

Hysteresis setting

Output operation

setting

Reset setting

Hold setting

ECO Setting

High precision

No timer

Zero set function

Normal sensing

mode

Hysteresis width

UP key : Increases hysteresis width

DOWN key : Decreases hysteresis width

Light-ON

Reset NG

Hold OFF

ECO OFF

Standard

OFF-delay

Teaching function

Dark-ON

Reset OK

Hold ON

ECO ON

High speed

ON-delay

Light emitting

stop function

Rising differen-

tial mode

One-shot

Trigger function

Trailing differen-

tial mode

UP / DOWN

UP /

DOWN

TEACH

UP /

DOWN

Display setting Normal Invert Offset

1-point teaching

Window com-

parator mode

2-point teaching

Window com-

parator mode

3-point teaching

Window com-

parator mode

13

ERROR INDICATION

●In case of errors, attempt the following measures.

Error indication Description Remedy

<Hold OFF>

<Hold ON>

Measured value blinks

Insufcientamountofreectedlight.

The sensing object is out of the sensing range.

Conrmthatthesensingdistanceiswithinthe

specicationrange.

Adjust the installation angle of the sensor.

Flash memory is damaged or passed its life expectancy.

Pleasecontactourofce.

Load of the sensing output is short-circuited

causinganover-currenttoow. Turn OFF the power and check the load.

The semiconductor laser is damaged or

passed its life expectancy. Pleasecontactourofce.

• Whenzeroset isset,the measurement is

not performed normally.

• Since the display setting is set to “Offset”,

thezerosetfunctioncannotbeused.

• Conrmthatthesensingdistanceiswithin

thespecicationrange.

•

Set the display to any setting except “Offset.”

During teaching, the measurement is not per-

formed normally. Conrmthatthesensingdistanceiswithinthe

specicationrange.

System error Pleasecontactourofce.

14

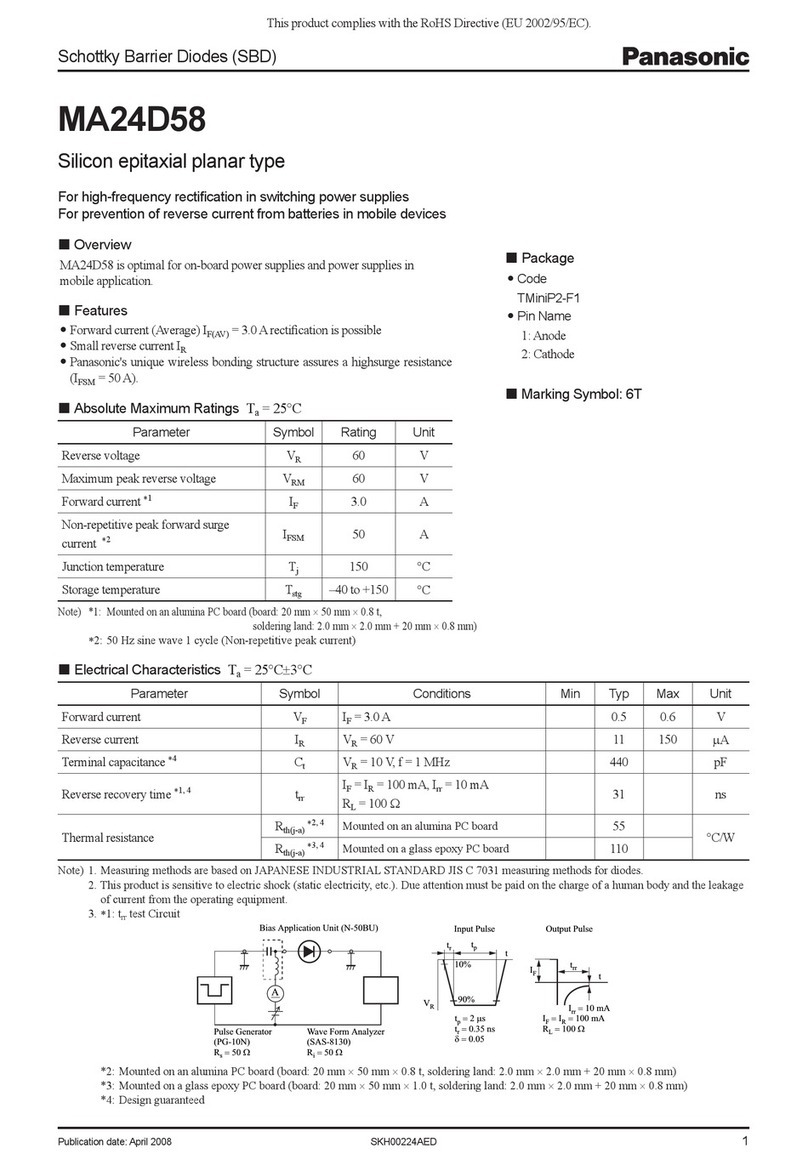

SPECIFICATIONS

Type

Measurement

center 30mm type Measurement

center 50mm type

Measurement cen-

ter 100mm type Measurement cen-

ter 200mm type Measurement cen-

ter 400mm type

Model No. NPN output HG-C1030 HG-C1050 HG-C1100 HG-C1200 HG-C1400

PNP output HG-C1030-P HG-C1050-P HG-C1100-P HG-C1200-P HG-C1400-P

Measurement center

distance 30mm 50mm 100mm 200mm 400mm

Measurement range ±5mm ±15mm ±35mm ±80mm ±200mm

Repeatability 10μm 30μm 70μm 200μm

300μm(measurement

distance 200 to 400mm)

800μm(measurement

distance 400 to 600mm)

Linearity ±0.1%F.S. ±0.2%F.S.

±0.2%F.S. (measurement

distance 200 to 400mm)

±0.3%F.S. (measurement

distance 400 to 600mm)

Temperature characteristic 0.03%F.S./°C

Light source Red semiconductor laser Class 2 [JIS / IEC / GB / FDA (Note 2)]

Max. output: 1mW, Emission peak wavelength: 655nm

Beam diameter (Note 3) Approx.

ø50μm

Approx.

ø70μm

Approx.

ø120μm

Approx.

ø300μm

Approx.

ø500μm

Supply voltage 12 to 24V DC ±10%, Ripple P-P 10% or less

Power consumption 40mA or less (at 24V DC supply voltage), 60mA or less (at 12V DC supply voltage)

Control output

<NPN output type>

NPN open-collector transistor

• Maximum sink current: 50mA

• Applied voltage: 30V DC or less

(Between control output to 0V)

• Residual voltage: 1.5V or less

(At 50mA sink current)

• Leakage current: 0.1 mA or less

<PNP output type>

PNP open-collector transistor

• Maximum source current: 50mA

• Applied voltage: 30V DC or less

(Between control output to +V)

• Residual voltage: 1.5V or less

(At 50mA source current)

• Leakage current: 0.1 mA or less

Output operation Switchable either Light-ON or Dark-ON

Short-circuit protection Incorporated (Auto reset type)

Analogue output • Output range: 0 to 5V (at alarm: +5.2V)

• Outputimpedance:100Ω

Response time Switchable between 1.5ms / 5ms / 10ms

External input

<NPN output type>

NPN non-contact input

• Input conditions

Invalid: +8 to +V DC or Open

Valid: 0 to +1.2V DC

• Inputimpedance:Approx.10kΩ

<PNP output type>

PNP non-contact input

• Input conditions

Invalid: 0 to +0.6V DC or Open

Valid: +4 to +V DC

• Inputimpedance:Approx.10kΩ

Protection IP67 (IEC)

Degree of pollution 2

Ambient temperature -10 to +45°C (No dew condensation or icing allowed), Storage: -20 to +60°C

Ambient humidity 35 to 85% RH, Storage: 35 to 85% RH

Ambient illuminance Incandescentlamp:Acceptancesurfaceilluminance3,000ℓxorless

Operating altitude 2,000m or less

Cable 0.2mm25-core composite cable, 2m long

Material Enclosure: Aluminum die-cast, Front cover: Acrylic

Weight Approx. 35g (without cable), approx. 85g (including cable)

Applicable standard EMC Directive Compliance, FDA Standard

Notes: 1)

Supply voltage: 24V DC, ambient temperature: +20°C, response time: 10ms, and analogue output value of

measurementcenterdistanceareusedforunspeciedmeasurementconditions.Thesubjectiswhiteceramics.

2) This is based on the FDA Standard, according to Laser Notice No. 50 of the FDA Standard.

3)

Thisisthesizeinthemeasurementcenterdistance.Thesevaluesweredenedbyusing1/e

2

(approx. 13.5%)

ofthecenterlightintensity.Due toleaklightoutsidethespecied area, thereectancearoundthedetecting

point may be higher than at the point and this may affect the measurement value.

15

CAUTIONS

●This product has been developed / produced for industrial use only.

●Make sure that the power supply is OFF before starting the wiring.

●If the wiring is performed incorrectly, it will cause a failure.

●Do not run the wires together with high-voltage lines or power lines, or put them in

the same raceway. This can cause malfunction due to induction.

●Verify that the supply voltage variation is within the rating.

●If power is supplied from a commercial switching regulator, ensure that the frame

ground (F.G.) terminal of the power supply is connected to an actual ground.

●If noise generating devices (switching regulators, inverter motors, etc.) are used

around the sensor mounting area, make sure to connect the frame ground (FG)

terminal of the device.

●Do not use this product during the transient state when the power supply is turned

ON.

●The overall length of the cable can be extended to 10m maximum with a cable

sizeof0.3mm2or more.

●Make sure that stress by forcible bend or pulling is not applied to the sensor cable

joint.

●Although it depends on the type, light from rapid start type or high frequency

lightingtypeuorescentlights,sunlightandetc.mayaffectthesensing,therefore

make sure to prevent direct incident light.

●This product is suitable for indoor use only.

●Keep water, oil, fingerprints and etc. which reflect light, or dust, particles or etc.

which interrupts the light, away from the emitting / receiving surfaces of this product.

If contaminants adhere to the surface, wipe off with a dust-free soft cloth, or lens

cleaning paper.

●Do not use the sensor in locations where there is excessive vapor, dust or etc. or

in an atmosphere where corrosive gases, etc. is generated.

●Take care that the product does not come in contact with oil, grease, organic sol-

vents such as thinner, etc., strong acid or alkaline.

●Make sure to turn OFF the power supply, before cleaning the light emitting / re-

ceiving windows of the sensor head.

●There is a certain deviation in the directionality of this product. Install the product

usingamountingbracketorsimilarttingtoallowtheadjustmentofopticalaxis.