INSTALLATION INSTRUCTIONS

Long range laser distance sensor

HG-F13A-A-□

MJE-HGF1 No.0088-41V

Thank you for purchasing a Panasonic product.

Read this Installation Instructions Manual carefully and follow them to install the prod-

uct correctly and safely.

Keep this manual in a safe location for reference whenever necessary.

In this Installation Instructions Manual, safety precautions are classied into

“ WARNING” depending on the level of hazard.

WARNING Indicates that there is a risk of death or serious injury

WARNING

Do not use this product as a sensing device for personal protection. Using this

product as a sensing device for personal protection will result in death or seri-

ous injury.

For sensing devices for personal protection, use products that conform to the

laws and standards related to personal protection in each country, such as

OSHA, ANSI, and IEC.

This product is intended to be used to detect target objects and is not provided

with control functions that prevent accidents to ensure safety.

Avoid observing beams in dark surroundings.

Do not look at beams using an optical device such as an optical telephoto system.

Never attempt to disassemble, repair, or modify this product.

Control or adjustment according to procedures other than those provided in this

Installation Instructions Manual and the separate User’s Manual may cause ex-

posure to hazardous emitted laser beams.

This manual provides a simple summary of installation procedures, etc.

For details, refer to the HG-F1 Series User’s Manual

(our website: https://industrial.panasonic.com/ac/e/dl_center/manual/ ).

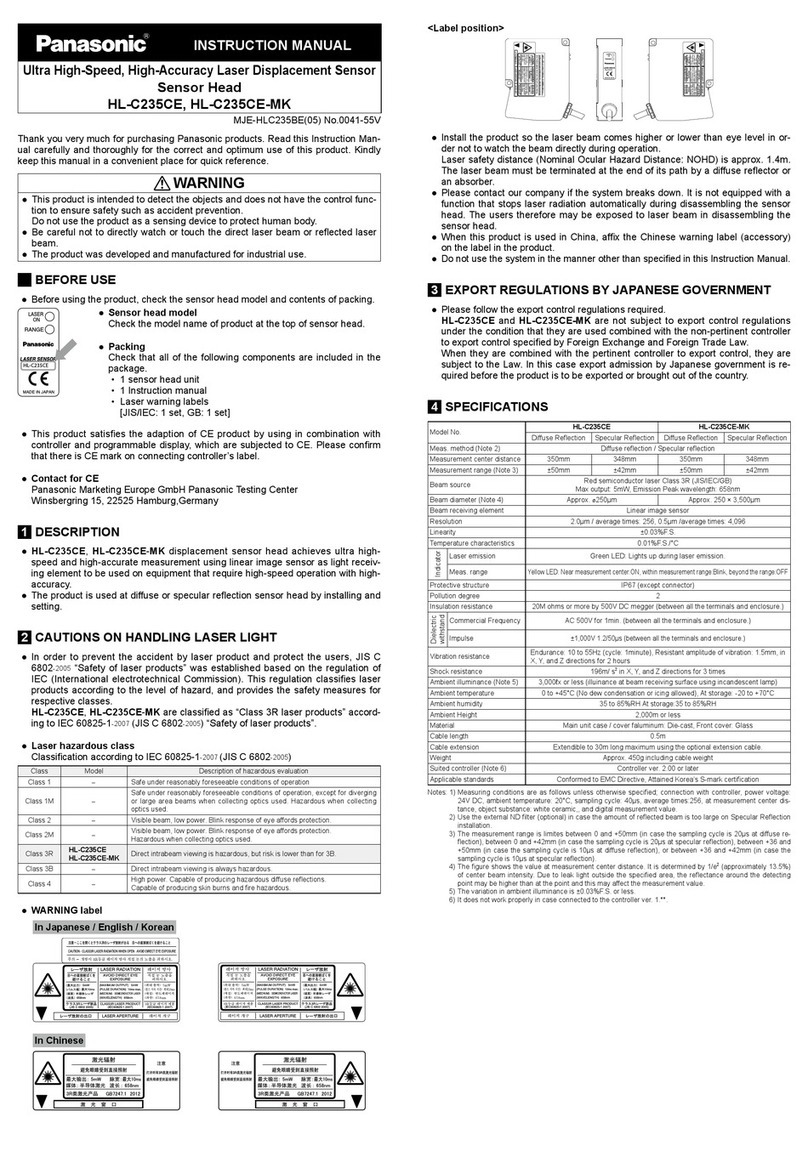

1REGULATIONS AND STANDARDS

●This product conforms to the standards and regulations below.

<Conformity Directives / Conforming Regulations>

EU Law : EMC Directive 2014/30/EU British Legislation : EMC Regulations 2016/1091

‒Applicable Standards

EN 61000-6-4, EN 61000-6-2

USA Regulation : FDA21 CFR 1040.10 and 1040.11 (Laser Notice No.56)

<Conforming Standards>

USA / Canada Standards : UL 61010-1, CAN/CSA No.61010-1

Other Standards : IEC 60825-1, JIS C 6802, GB 7247.1,

KS C IEC 60825-1

Note: When using this product in a region other than those listed above, be sure to check and com-

ply with the regulations and standards applicable in the country or region where the product

is used.

2SAFE USE OF LASER PRODUCT

IEC / JIS / GB / KS

●To prevent laser products from aecting their users, IEC, JIS, GB, and KS have

respective standards.

These standards classify laser products into classes according to the hazard level

of laser, and prescribe safety and preventive measures that should be implement-

ed for each class.

This product belongs to “Class 1 laser product” according to IEC 60825-1(JIS C

6802, GB 7247.1

,

KS C IEC 60825-1) “Radiation Safety of Laser Products”.

●Explanation of hazard levels

Classication Summary of hazard evaluation

Class 1 A laser that is safe when operated under operating conditions that can be reasonably foreseen.

Note: Pay attention to safety since hazardous laser beams may be emitted in the event of an unex-

pected failure.

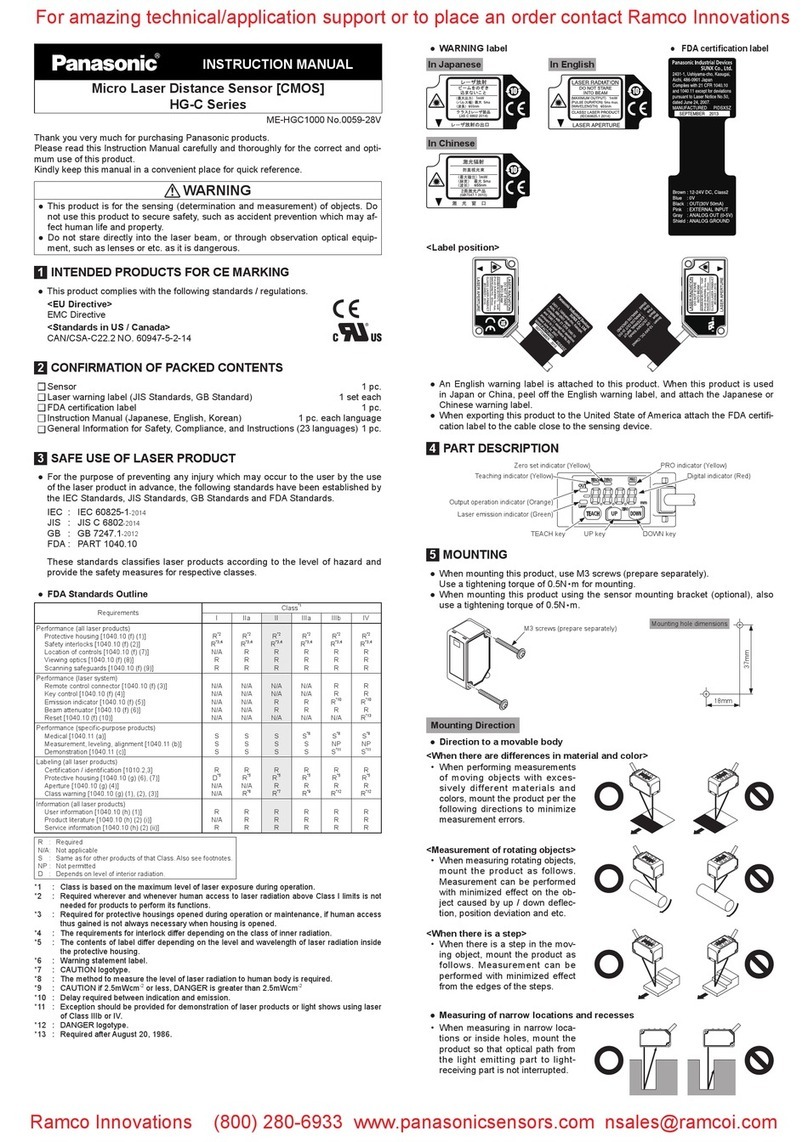

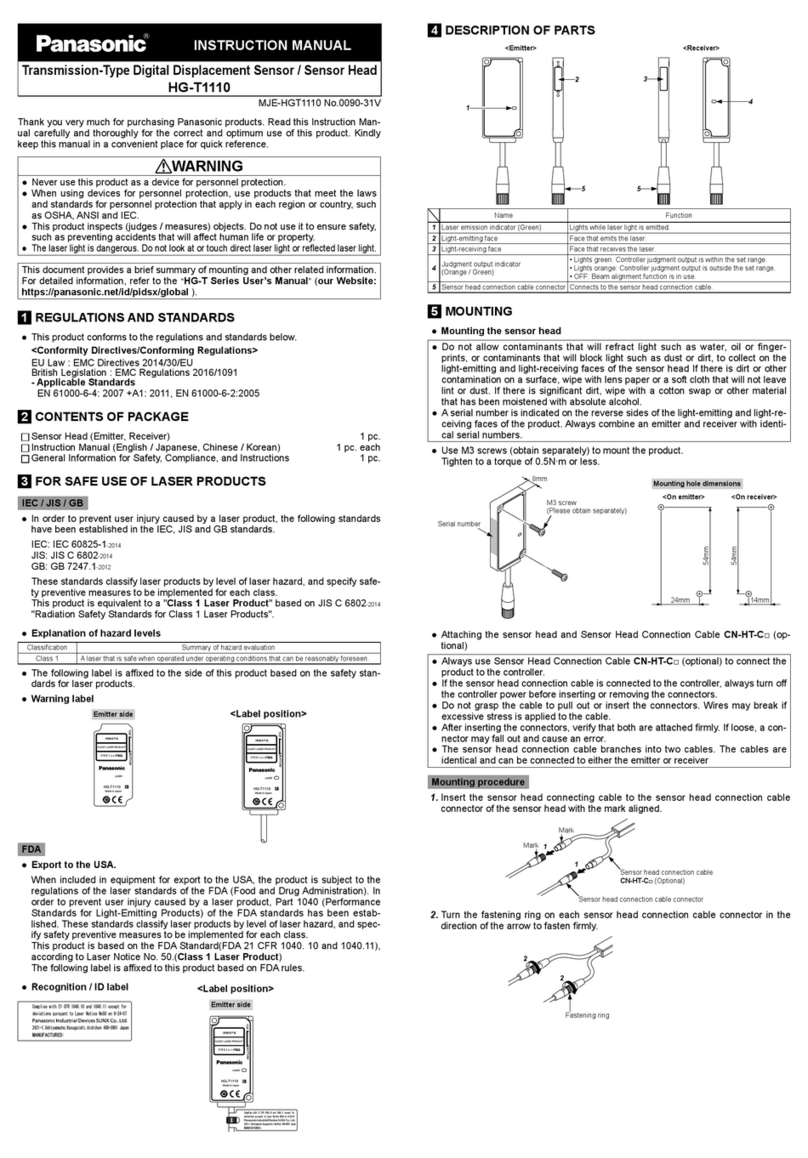

●The following label is axed to the side of this product based on the safety stan-

dards for laser products.

●Warning label

<Label axed position>

FDA

●Exporting to the USA

If this product is incorporated into facilities or equipment to be exported to the

USA, it is subject to the laser regulations of the U.S. Food and Drug Administra-

tion (FDA). To prevent laser products from aecting their users, PART1040 (Per-

formance Standards for Light-Emitting Products) was established as one of the

FDA regulations. These standards classify laser products into classes according

to the hazard level of laser and prescribe safety and preventive measures that

should be implemented for each class.

This product complies with the FDA regulations (FDA 21 CFR 1040.10 and

1040.11) in accordance with FDA Laser Notice No. 56, except for complying with

IEC 60825-1 Ed. 3. (Class 1 Laser Product)

When exporting this product to the USA, ax the FDA certicate / identication

label near the end of the cable.

For details on standards, refer to the HG-F1 Series User’s Manual

(our website: https://industrial.panasonic.com/ac/e/dl_center/manual/ ).

● FDA certicate / identication label

<Label axed position>

3CAUTIONS

Specications

●This product has been developed / produced for industrial use only.

●

Do not use this product outside the range of the specications. Doing so will cause an

accident or product failure. There is also a risk of a noticeable reduction of service life.

●

There is a certain deviation in the directionality of this product. When using this product, install

the product using a mounting bracket or similar tting to allow the adjustment of beam axis.

●The internal memory (non-volatile memory) of this product has a service life. Set-

tings cannot be congured more than one million times.

●Leaked light exists around the detection point, and if an object with high reec-

tance is present around the detection point, this product may be aected by that.

●If a regular reection light enters the beam receiving window, proper measure-

ment may not be possible. If the reectance of the detected object is high, careful-

ly select the installation location.

Power Supply

●Verify that the supply voltage fluctuations are within the rating when using the

product. Note that applying a voltage greater than the rated voltage or directly ap-

plying AC power will cause damage or burning.

●To ensure performance, use the product at least 30 minutes (warm-up time) after

the power is turned ON.

●If power is supplied from a commercial switching regulator, ensure that the frame

ground (F.G.) terminal of the power supply is connected to an actual ground.

● Make sure that the power supply input satises the following items.

1) The power supply unit must be certied for use in your region.

2) The power supply unit must have an output holding time of 20 ms or more.

3) The power supply unit must have the rated output voltage of 24 V DC± 10%

and the ripple (P-P) of 10% or less.

4) The power supply unit must provide SELV (safety extra low voltage) or PELV

(protective extra low voltage) conrming to the EMC Directive if the CE mark-

ing compliance is required.

5) The power supply unit must provide SELV (safety extra low voltage) or PELV

(protective extra low voltage) conrming to the EMC Regulations if the UKCA

marking compliance is required.

6)

The power supply unit must support Class 2 if CTÜVUS marking compliance is required.

●If surges occur, take countermeasures such as connecting a surge absorber to

the source of the surges.

Wiring

●Before wiring work always turn the power OFF.

●Do not wire in parallel with a high-voltage line or power line, or run through the

same conduit. Doing so may result in malfunctioning due to induction.

● Arrange the load to ensure that a current of 50 mA or higher does not ow to the

control output line. Also avoid incorrect wiring such as polarity connection error of

the power supply. Failure to do so will cause damage or burning.

●The overall length of the cable can be extended to 10m maximum with a cable

size of 0.3 mm2or more. Use a shielded cable to extend the analog line.

●

Do not apply stress such as excessive bending or pulling to the extracted part of a cable.

Usage Environment

●This product is suitable for indoor use only.

●Do not install the sensor in the following locations.

• Locations subject to ammable gas, corrosive gas, or excessive dust

• Locations subject to dust, metal particles, or saline matter

• Locations subject to benzine, paint thinner, alcohol or other organic solvents or

strong alkaline solutions such as ammonia or caustic soda

• Locations subject to severe vibration or shock

• Locations subject to direct sunlight

• Locations subject to water, oil, or chemicals

• Locations where load is applied to the sensor

●Avoid using this product in environments where condensation occurs due to sud-

den temperature change.

● Performance may not be satisfactory in a strong electromagnetic eld.

● Take care that the sensor is not directly exposed to uorescent lamp from a rap-

id-starter lamp, a high frequency lighting device or sunlight etc., as it may aect

the sensing performance, although it depends on the type.

●Keep the light emitting and receiving windows of this product clean and free of

water, oil, ngerprints, and other substances that refract light as well as dust, grit,

and other objects that intercept light. When cleaning the surfaces, wipe o con-

taminants with a lint-free soft cloth or lens cleaning paper.

●Make sure to turn OFF the power supply before cleaning the light emitting and

receiving windows of this product.

●This product is a precision device. Do not drop or otherwise subject to shock. Do-

ing so will cause product failure.

●If a background object is present at the specic region shown below, a distance

dierent from the actual distance may be displayed owing to the sensing principle.

Please check actual operation in the actual usage environment.

0 3 10 20 30 40 49 (m)

…

24

29 54

Out of measurement range Out of measurement range

Specic region

Specication measurement range

If there is any object in the specic region, block the laser beam within the range

of less than 24 m.

Other Matters

●When this device becomes inoperable or unnecessary, dispose of the product

properly as industrial waste by abiding by the applicable law in the country.