2

Service Bulletin 33-00C August 2005

through the adapter and down through the pilot port to

the top of the piston. This forces the piston downward and

pushes the main port plug open, thereby permitting flow

of the refrigerant through the valve. The closing spring

meanwhile is held in a compressed position.De-energizing

of the solenoid coil permits the spring-assisted plunger

to reseat, stopping the flow through the pilot port. Bleed-

off, through the bleed hole in the piston, decreases the

pressure above the piston and allows the closing spring

to force the main port plug upward into a closed position

to stop the flow. The pressure difference across the valve,

acting upon the area of the valve seat, plus the force of

the closing spring, holds the main port plug in a tightly

closed position.

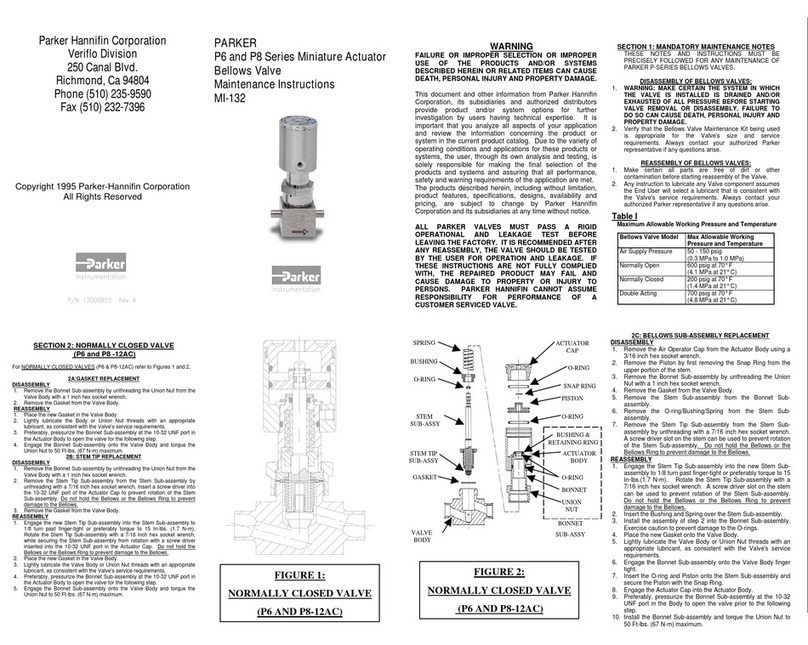

MANUAL OPENING STEM

The manual opening stem on the SC solenoid is for the

purpose of opening the valve without energizing the

solenoid coil. Refer to the exploded view and the parts

list for location of the stem and other related parts. For

access to the stem, the seal cap must be removed. This

must be done with caution as refrigerant may be trapped

inside the seal cap. Manual opening is accomplished

by turning the stem counter clockwise until stopped. To

reset for automatic operation turn stem clockwise until

seated.

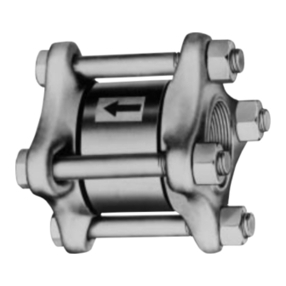

INSTALLATION

The solenoid valve can be mounted in a horizontal or

vertical line with the flow in the direction of the arrow on

the valve body. Protect the inside of the solenoid valve

from moisture, dirt and chips during installation. These

valves may be soldered into the line without disassem-

bly. A wet cloth should be wrapped around the valve

and the soldering flame should be directed away from

the valve body.The SC solenoid valve must be installed

with the arrow on the valve body in the direction of flow

through the valve. If the valve is backwards, the flow will

not be stopped when the valve is electrically de-ener-

gized. Like all Solenoid Valves, the SC can stop flow only

in the direction from normal inlet to normal outlet (as

shown by the arrow on the body). If reversal of pressure

occurs in the system so the outlet pressure exceeds the

inlet pressure, the plug will be blown away from its seat

and reverse flow will occur. If a system has this type of

pressure reversal, a check valve such as Refrigerating

Specialties Division Type CK4A in series with the sole-

noid valve will prevent flow reversal. (The CK4A must be

installed downstream of the solenoid to avoid trapping

liquid when the solenoid is de-energized.)

ELECTRICAL

The Refrigerating Specialties Division molded water

resistant Class “F” solenoid coil, which is standard

on the SC solenoid, is designed for long life and pow-

erful opening force. The standard coil housing meets

NEMA 3R and 4 requirements. This sealed construction

can withstand direct contact with moisture and ice.

The Class “F” solenoid coil and splice box housing

should be used on low side applications only. Due to

the lower temperature rating of the Class “F” coil, it

should not be used with solenoid valves applied to high

side duty. For those applications, the Class “H” coil and

the general purpose housing should be used which are

standard on Parker Refrigerating Specialties Division

S81 and S82 solenoid valves.

A solenoid coil should never be energized except when

mounted on its corresponding solenoid tube.

The molded Class “F” coil is available from stock with

most standard voltages. However, coils are available for

other voltages and frequencies.

The solenoid coil must be connected to electrical line

with volts and Hertz same as stamped on coil. The

supply circuits must be properly sized to give adequate

voltage at the coil leads even when other electrical

equipment is operating. The coil is designed to operate

with line voltage from 85% to 110% of rated coil voltage.

Operating with a coil voltage above or below these limits

may result in coil burnout. Also, operating with a coil

voltage below the limit will definitely result in lower-

ing the valve’s maximum opening pressure differential.

Power consumption during normal operation will be

10.2 watts or less.

The coil housing washer (item #40) should be installed

on the solenoid operator (#36), before the coil housing

(#39) and the coil cover clip (#41) are installed.

This “Stack-up” maintains the coil firmly in place and

prevents excessive vibration of the entire coil housing

assembly when the coil is energized.

SERVICE POINTERS

1. Failure to Open: (a) Coil is of incorrectly high

voltage. See “Electrical”. Check voltage printed on the

coil. (b) Line voltage is abnormally low. See “Electri-

cal”. Check line voltage at coil leads with a voltmeter. (c)

Failure to electrically energize. Check control circuit. (d)

Pressure difference across valve is too high. The SC will

open against a maximum pressure difference across

the valve of 21 bar (300 psig). (e) Solenoid Coil is burned

out. See “Electrical”, and replace with proper coil. (f)

Plunger Assembly is sticking. To disassemble the SC

for inspection of internal parts (after pumping out the

system as required): disconnect power source to Sole-

noid Coil, remove (#36) Solenoid Operator Assembly,

then Adapter. Remove every trace of dirt from Adapter

and Cartridge Assembly. Thoroughly clean all parts and

reassemble using a light film of refrigerant oil.

2. Failure to Close: (a) Electrical control circuit

is not opening properly. Check wiring and controls. (b)

There are chips or dirt on the Pilot Seat or the Piston

Plug Seat , preventing proper seating.