159 Parker Hannifin Corporation

Hydraulic Accumulator Division

Rockford, Illinois USA

Catalog HY10-1630/US Hydraulic Accumulators

Maintenance Instructions

General

Information

Bladder Accumulators

FIGURE6

PART #870810 XX00 FIGURE7

PART #871372 XX00

Part Number Valve Extension for 3000 PSI

085434 XX00 Contains extension and valve core.

25-40GALLON 3000 PSI AND ALL 5000 PSI UNITS

Part Number Charging and Gauging Assemblyfor 25-40 Gal. 3000 &5000 PSI

870810 XX00 Charging and Gauging Assembly consists of10'charging hose with

standard right-hand thread nitrogen fittings (1.035-14 NGO female)

adapter incorporating gas valve bleeder valve and gas chuck

(less gauge).

Part Number Gauging Assemblyfor 5000 PSI

871372 XX00 Gauging device consisting of adapter incorporating gas valve

bleeder valve and gas chuck (less gauge).

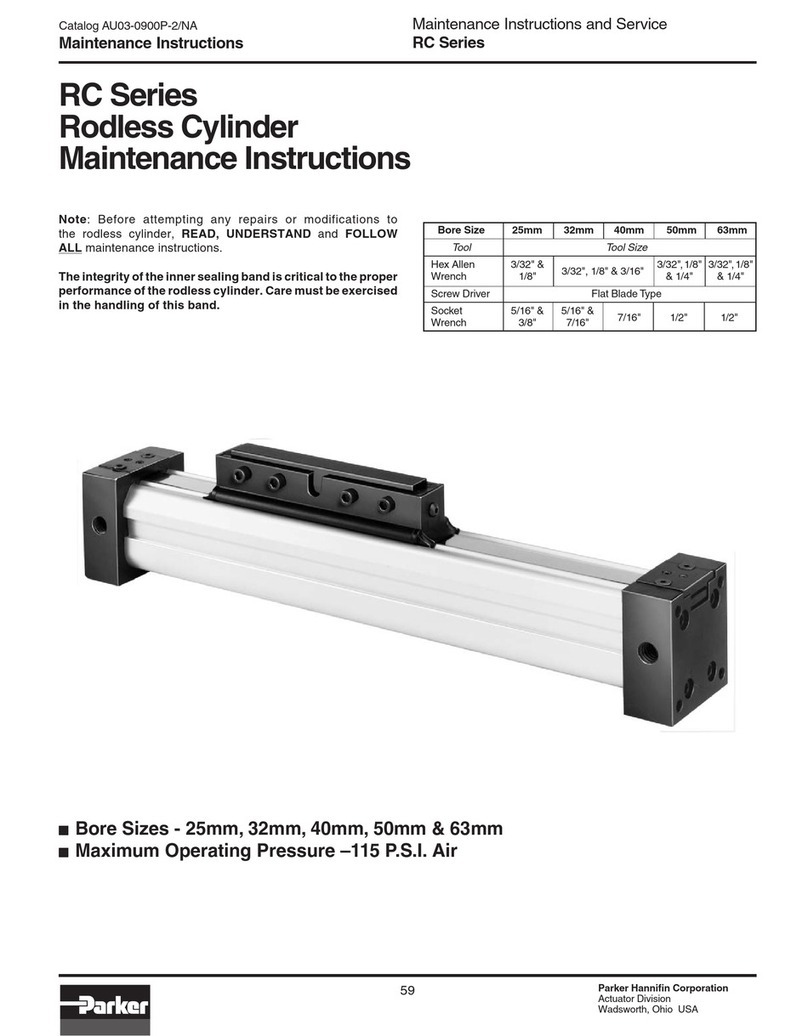

FIGURE8AFIGURE8BFIGURE9

3000 PSIVALVES 5000 PSIVALVES

For accumulators rated for 5000 psi, use gaging assembly in Figure

7(Part#871372XX00) and follow steps 8 through 14.

3000 PSI RATED UNITS

(1) Remove gas valve guard and gas valve cap.(For top repairable

unit connect valve extension Part #085434XX00) as shown in

Figure 3 and tighten with wrench.

(2) Close bleed valve and turn “T”handle all the way out.

(3a) Attach gauging assembly to gas valve or to gas valve extension

and tighten swivel nut (10-15 in.lb.) (11.5-17 cm kg), when using

gauging assembly in Figure 1.

(3b) Install gas valve o-ring on the gas valve, and attach gauging

assembly to valve stem.Tighten assembly (25-30 in.lb.) (29-35

cm kg) when using gauging assembly in Figure 4.

(4) Turn “T”handle all the way down, which will depress core in gas

valve and check pressure.

(5) To remove gauging assembly, turn “T” handle all the way out and

then open bleeder valve.

(6) Hold gas valve from turning, loosen swivel nut and remove

assembly.

(7) If necessary, remove valve extension, then install cap on gas

valve (10-15 in.lb.) (11.5-17 cm kg) and valve guard.

25-40 GALLON 3000 PSI AND 5000 PSI RATED UNITS EQUIPPED

WITH MS GASVALVE AS SHOWN INFIGURE9.

(8) Remove gas valve guard and gas valve cap.

(9) Close bleed valve.

(10) Attach gauging assembly to gas valve and tighten swivel

nut (10-15 in.lb.) (11.5-17 cm kg).

(11) Referring to Figure 9, hold gas valve at point “C” with one (1)

wrench while unscrewing hexnut at point “D”with a second

wrench.This will open the poppet inside the gas valve.Note, four

(4) turns will fully open poppet.Check pre-charge pressure.

(12) With wrench, tighten hexnut at point “D”to close internal

poppet (10-15 in. lb.) (11.5-17 cm kg).

(13) Hold gas valve at point“C” with a wrench and remove

swivel nut assembly.

(14) Replace cap on gas valve (10-15 in.lb.) (11.5-17 cm kg) and

install gas valve guard.

Removal of Accumulator From

Hydraulic System

Shut equipment down and make certain that hydraulic pressure at the

accumulator is at zero.

Remove gas valve guard and gas valve cap.

3000 PSI RATED UNITS

Accumulators rated for 3000 psi will have a gas valve as shown in

Figure 8A or 8B.For these units, attach gaging assembly (Part

#085122XX00) or (Part #087103XX00)for 10 - 150 cubic inch, and

(Part #087101XX00) for 1-15 gallon.

Open bleed valve and release all the gas pressure.Detach gauging

assembly and, using valve core removing tool (Part #582441XX00),

remove valve core.

Remove accumulator from hydraulic system.

25-40 GALLON 3000 PSI AND 5000 PSI RATED UNITS EQUIPPED

WITH MS GASVALVE AS SHOWN INFIGURE9.

Accumulators rated for 5000 psi will have a gas valve as shown in

Figure 9. For these units, after removing valve cap, hold valve at point

“C” with one (1) wrench while unscrewing hexnut at point “D” with a

second wrench until gas begins to escape through the top of the valve.

Wait until all the gas pressure has been released.

(Caution:Keep face away from gas valve as the high pressure nitrogen

is discharging.)

Remove accumulator from hydraulic system.

Part Number Gauging Assemblyfor 3000 PSI Bottom Repairable

085122 XX00 Gauging device consisting of adapter incorporating gas valve

bleeder valve and gas chuck including gauge.

Part Number Charging and Gauging Assembly

for 3000 PSI Bottom &Top Repairable

087102 XX00 Charging and Gauging Assembly consists of10'charging hose with

(10-150 cu. in.) standard right-hand thread nitrogen fittings adapter incorporating

087100 XX00 gas valve bleeder valve and gas chuck (less gauge).

(1-15 gal.)

Maintenance

Little maintenance is required for a bladder accumulator.If there is

external leakage, tighten all connections.If leakage continues, remove

accumulator from system and replace faulty components.

After original installation, check pre-charge once during first week to

see that no leak has developed.Thereafter, check pre-charge monthly.

Check pre-charge if the system is acting sluggish.If pre-charge is low,

check gas valve for leakage and recharge.

If there is no gas in bladder and fluid appears at gas valve, unit must

be removed and bladder replaced.

Pre-charge Checking Procedure

Using appropriate valve in the hydraulic system, discharge all oil from

accumulator.

For accumulators rated for 3000 psi, either use gaging assembly in

Figure 2 (Part #085122XX00) or gaging assembly in Figure 5 (Part

#087101XX00) and follow Steps 1 through 7.

Part Number Charging and Gauging Assemblyfor 3000 PSI Bottom Repairable

144595 XX00 Charging and Gauging Assembly consists of10'charging hose with

(Std) standard right-hand thread nitrogen fittings adapter incorporating

(Right Hand) gas valve bleeder valve and gas chuck (less gauge).For left-hand

thread nitrogen bottle fitting specify part number 144596 XX00.

Part Number Gauging Assemblyfor 3000 PSI Top Repairable

087103 0XX00 Gauging device consisting of adapter incorporating gas valve

(10-150 cu. in.) bleeder valve and gas chuck (less gauge).

087101 0XX00

(1 - 15 gal.)