2

1 - Convert the

boiler from Natural

Gas to Propane gas

or viceversa

Contents:

This conversion kit is composed of

the following elements, which are

necessary for the gas change:

- a label rating the new gas setting;

- this instruction sheet;

- an orice (see Table 1 for the

stamping reference);

Installing:

in order to make the gas change

please follow the instructions below:

1 - turn off power to the boiler;

2 - open the boiler’s casing;

3 - open the instrument panel (Follow

Section 2);

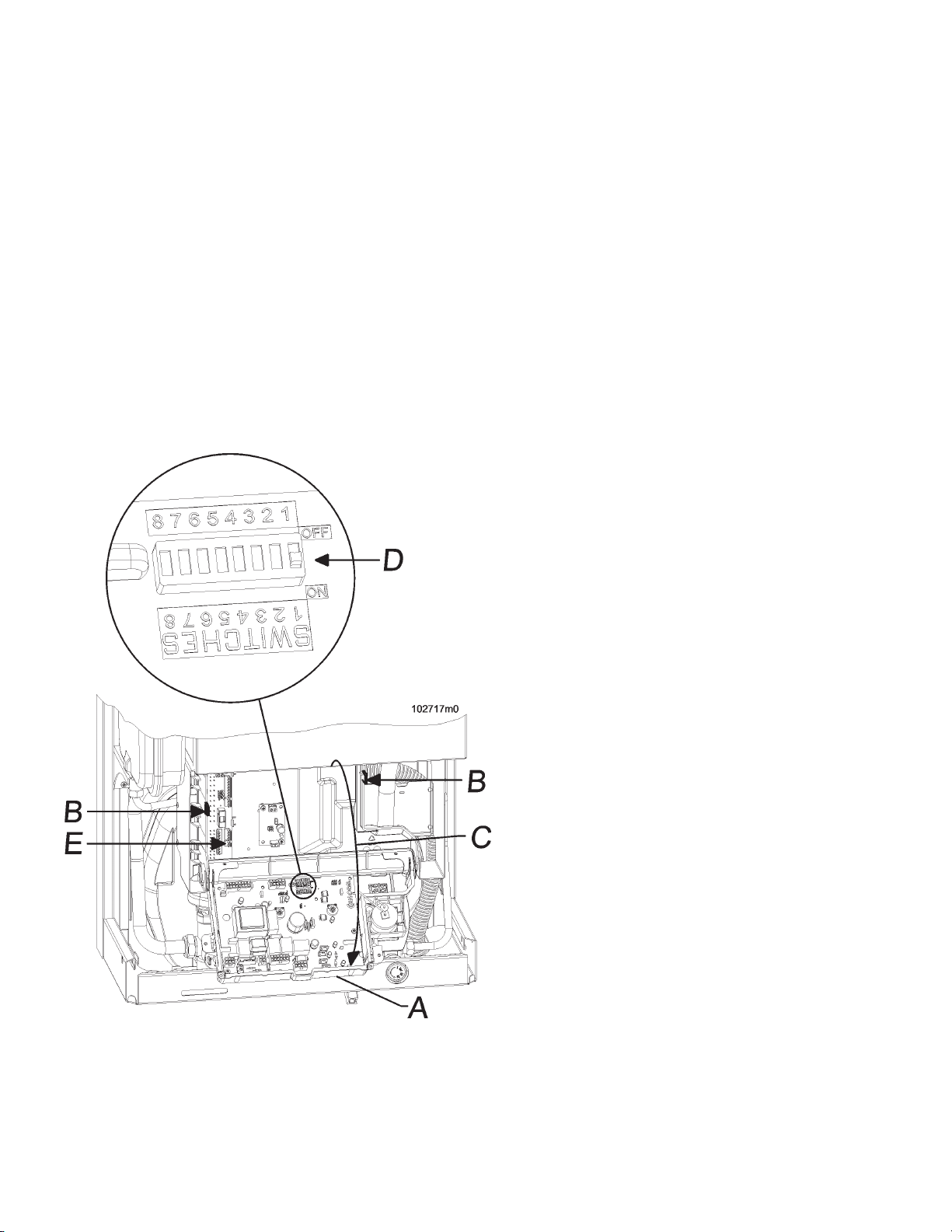

4 - Move switch #7 (see Figure 4)

from OFF position to ON position;

5 - turn on power to the boiler;

6 - on the boiler’s display you’ll see

followed by a number;

7 - using the push buttons and

set the input to:

- 61 to convert the boiler from LP

GAS to NATURAL GAS

or

- 62 to convert the boiler from

NATURAL GAS to LP GAS,

8 - push button to save the

new value;

9 - turn off power to the boiler;

10 - Move switch #7 (see Figure 4)

from ON position to OFF position;

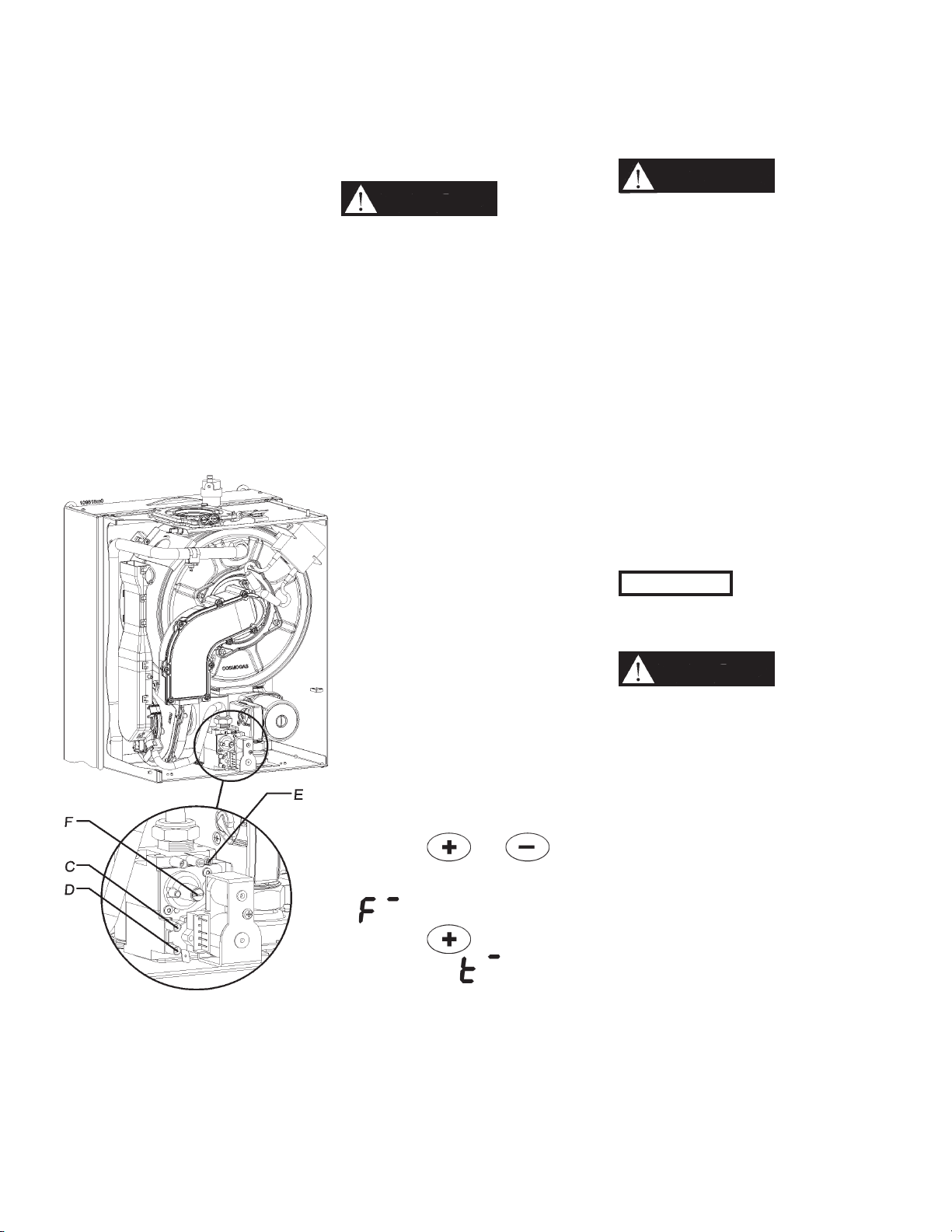

11 - Replace the orice item “C” of

Figure 1 for the correct one for the

type of gas used. Verify that the

stamping on the orice matches the

gas type (See Table 1).

11 - turn on power to the boiler;

12 - Turn completely counter

clockwise the screw E of Figure 1;

13 - Checking gas supply pressure

following Section 3. The Gas supply

pressure must be between the

maximum and minimum value as

stated in Table 1.

14 - Verifying the CO2 rate and its

eventual adjustment following

Section 4: The boiler during its

normal operation, has a CO2

exhaust rate as shown in Table 1.

If not within range of value shown,

malfunctions will occur.

WARNING!!! The CO

(carbon monoxide) level should

not exceed values given in

Table 1, when combustion is

correct. Failure to comply with

this requirement could result in

severe personal injury, death or

substantial property damage.

Gas Type TY value

setting

Min.

supply

pressure

Max.

supply

pressure

Orice CO2

content at

high re

CO2

content at

low re

O2

content at

high re

O2 content

at low re

CO content at

high and low re

/ / in.W.C. in.W.C. Stamping % % % % ppm

Natural gas 61 3 13 9.1 9.2 ± 0.1 8.7 ± 0.3 4.5 ± 0.1 5.4 ± 0.3 less than 150

LP gas 62 3 13 5.7 9.5 ± 0.2 9.5 ± 0.3 6.4 ± 0.2 6.4 ± 0.3 less than 250

Table 1 - Settings of the boiler for NATURAL GAS and LP GAS

WARNING!!! All

combustion measurements

must be performed with

calibrated equipment to ensure

proper reading and accuracy.

Failure to comply with this

requirement could result in

severe personal injury, death or

substantial property damage.

WARNING!!! If the

combustion levels are not

within the range given in

Table 1 for the ring rate, shut

the boiler down and contact

your distributor or the boiler

manufacturer (see reference in

the last cover page). Failure to

comply with this requirement

could result in severe personal

injury, death or substantial

property damage.

15 - Attach to the front of the boiler the

appropriate conversion label, found

in the conversion kit (see Figure 2

or Figure 3), stating the new type of

gas adjustment of the boiler.

a - Apply the label in Figure 3 if the

boiler has been converted to LP

GAS;

b - Apply the label in Figure 2 if the

boiler has been converted to

NATURAL GAS.