MC • Edition 01.19 • Nr. 259 959

5 … 24

Betriebs- und Montage-

anleitung

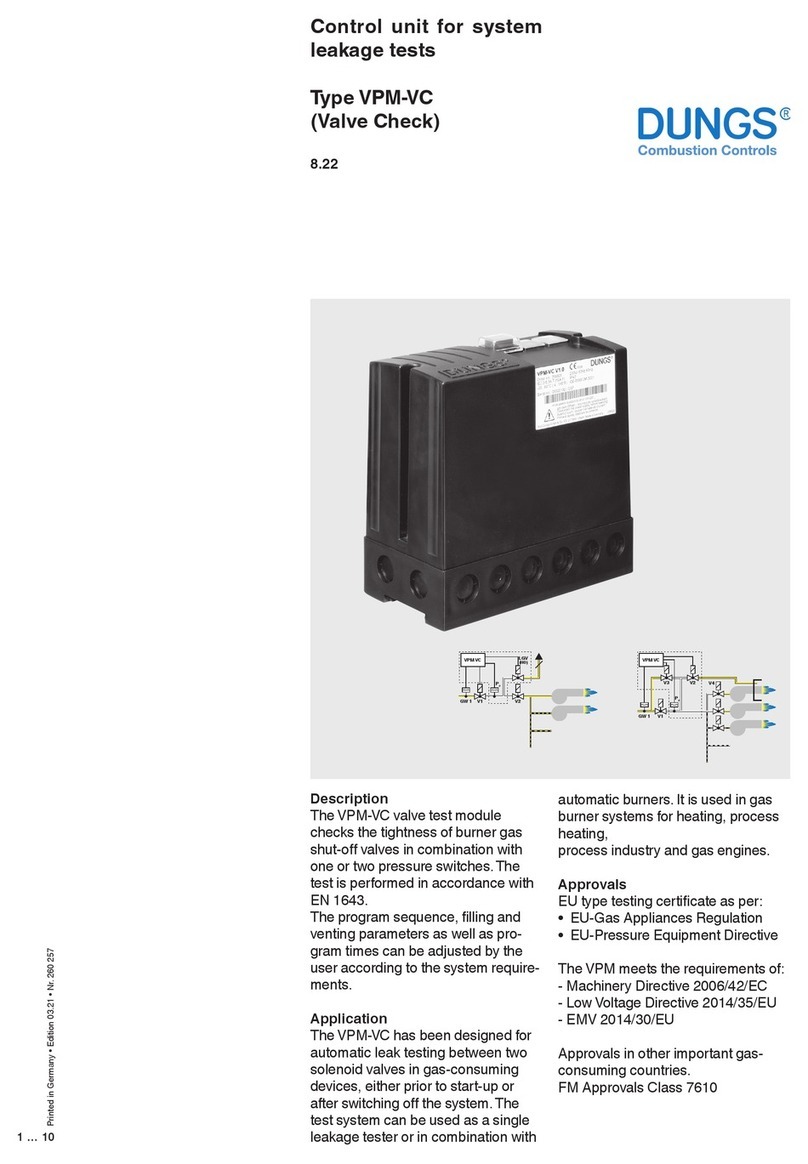

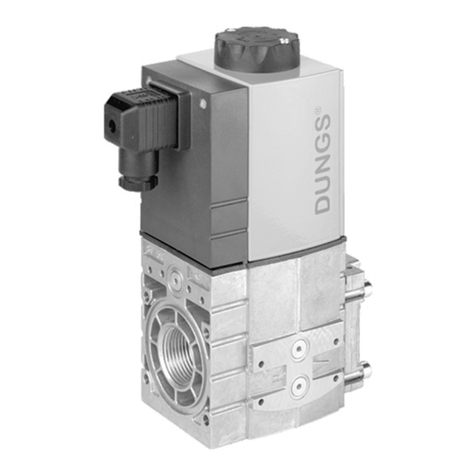

Steuergerät für System-

Dichtheitsprüfungen

Typ VPM-LC

(Line Check )

Operation and assembly

instructions

Control unit for system

leakage tests

Type VPM-LC

(Line Check )

Notice d‘emploi et

de montage

Appareildecommandepour

le contrôle de l‘étanchéité

du système

TypeVPM-LC (Line Check )

Istruzioni di esercizio

e di montaggio

Apparecchio di comando

per prove di tenuta del

sistema

TypVPM-LC (Line Check )

Betriebsanleitung

bitte lesen und aufbewahren.

-

sonal durchgeführt werden.

to carry out work.

This unit must be installed in ac-

cordance with current regulations

Leggeree conservareleistruzioni

di esercizio.

I lavori devono essere eseguiti

UnsachgemäßerEinbau, Einstel-

lung, Veränderung, Bedienung

oder Wartung kann Verletzungen

oder Sachschäden verursachen.

Dieses Gerät muß nach den-

geltenden Vorschriften installiert

werden.

-

tenance may result in injuries or

material damage.

This unit must be installed in ac-

cordance with current regulations

Inhaltsverzeichnis

Technische Daten / Ausführung ..2

Abmessungen / Elektrischer

Anschluß.....................................3

Klemmenbeschreibung...............4

Ausgänge / Eingänge..................5

LED-Anzeigen.............................6

Blinkcode....................................7

Anwendungshinweise / Kontroll-

druckwächter ..............................8

..................9

Programmablauf/

Ablaufverhalten.........................10

Statebeschreibungen / Ansteue-

rung Prüfablauf / LED-Anzeige..11

Anmerkungen Prüfablauf / Einstel-

lungen DIP ................................12

Prüfablauf .................................13

Prüfzeit berechnen....................14

Prüfvolumen........................ 15-16

Leckgasrate / Zubehör VisionBox /

...................17

Warnhinweise ...........................18

Sicherheitsrelevante

.............................19

Table of Contents

Technical data / Version ....................2

Dimensions / Electrical connection ...3

....................4

.................................5

.....................................6

Flash code........................................7

....................8

........................9

Program sequence/

.......................10

..................11

Notes on the test sequence /

DIP settings ....................................12

Test sequence.................................13

Calculation of the test time..............14

Determination of the test volume . 15-16

Leakage gas rate / VisionBox

.....17

Warnings.........................................18

Safety-relevant

......................................19

Indice

Dati tecnici / versione........................2

Dimensioni / connessione elettrica ...3

Descrizione dei morsetti ...................4

Uscite / entrate..................................5

...........................................6

........................7

.....................8

.....................9

..........10

Descrizione dello stato /

attivazione del decorso

...................11

.............................12

Decorso del controllo......................13

..............14

................... 15-16

........17

Avvertenze......................................18

...............................19

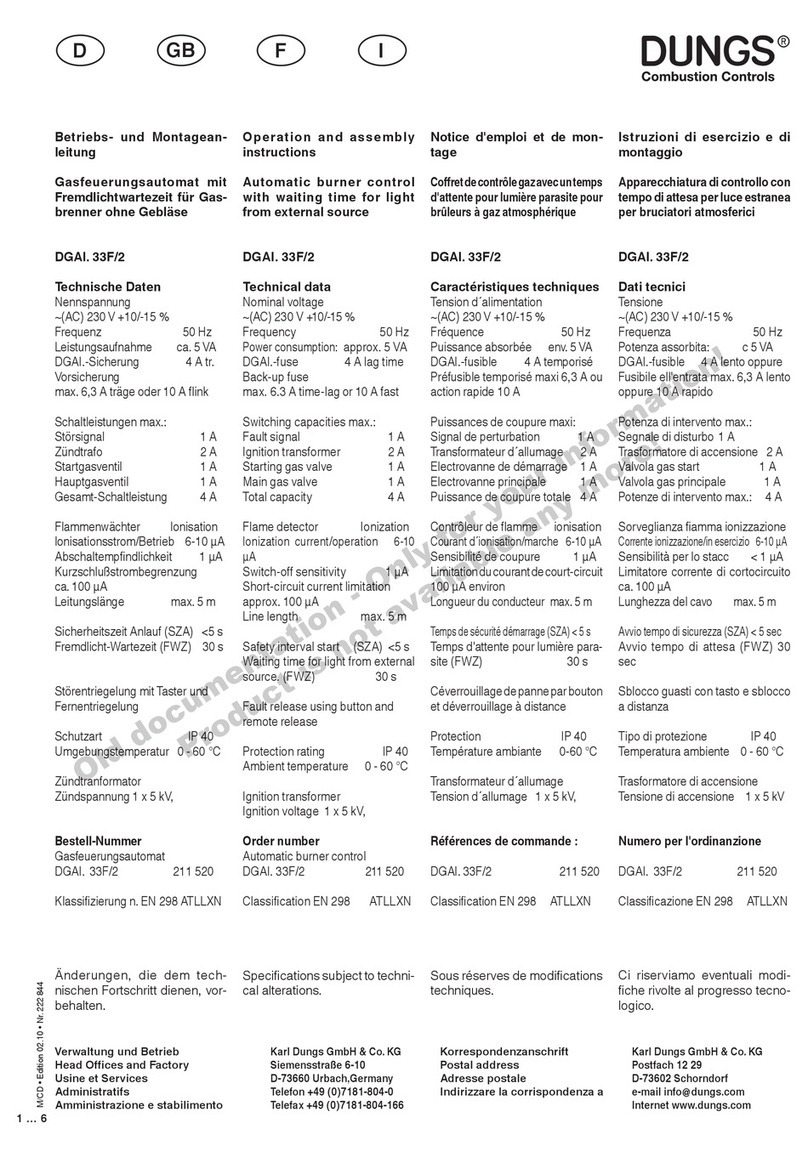

VPM-LC

nach / acc. / selon / a norme

DVGW G621: 2009

DVGW G 631: 1998

Testedin

accordance with /

/ Controllato in base a

DIN EN 298: 2004, Ber. 1: 2006

DIN EN 13611 prA2:2010: 2008

DG-4115CM 0413

Richtlinien / Directives /

Directives / Direttive

2004/108EG

2006/95/EG

2006/42/EG

VPM-LC

Table des matières

version.................................................. 2

.......3

...................... 4

...................................5

Indicateurs DEL ...................................6

Code de clignotement..........................7

.........................8

........................9

..................................10

Indicateurs DEL .................................11

Remarques concernant le

..12

......................13

...................14

volume de contrôle........................15-16

Taux de fuite /

accessoires VisionBox /

................17

Avertissements ..................................18

........................................19

Veuillez lire et conserver le mode

-

de maintenance ainsi que toute modi-

règlements en vigueur.

Nel caso di eseguire il montaggio,

-

do o la manutenzione in modo non

e danni materiali.

-

zioni in vigore.