22

Page 13 Pneumatic Tubing Requirements

Protective Gas Supply Requirements, Pneumatic

Connection Requirements

Page 14 Tubing Installation

LH, RH, TM, BM, WM, FM & PM Tubing

Configurations

Page 15 Tubing Connection Diagrams

LH, RH, TM, BM, WM, FM, & PM Configuration

Connection Points, Pneumatic Diagram

Page 16 Conduit Installation

Electrical & WPS Style Conduit and Connection

Parts

Page 17 Set-Up Procedure

Class I & Class II Set-up

Page 18 Operating Sequence

Class I & Class II Operation

Page 19 Troubleshooting Procedures

Troubleshooting Chart

Page 20 Warranty and Liability Statement

Warranty Notes, General Terms, Limitations

Page 21 System Maintenance

Regular Maintenance, Long-term Maintenance,

Maintenance Schedule

Page 22 Customer Notes

Page 24 Systems Identification & Application

Information

Important Notes

One (1) permanent file copy and one (1) operations copy of

this Manual must be studied and retained by the operator of

this System. User’s Agents are responsible for transferring

this Manual to the user, prior to start-up.

The contents of this manual have been arranged to allow the

use of this product as a stand-alone device on equipment

and enclosures supplied by the user or its agents. The

Manual’s parameters encompass a combination of both

National Fire Protection Association (NFPA) requirements

and Pepperl+Fuchs, Inc. requirements. Pepperl+Fuchs

therefore acknowledges the use of NFPA 496 as a guideline,

that we have enhanced certain NFPA requirements and that

additional information has been compiled to complete this

document. The Manual is intended as a complete guide and

must be considered, unless specifically stated otherwise,

that all directives contained herein are requirements for safe,

practical and efficient use of this product.

This System is not intended for use to protect enclosures

or devices which contain ignitable concentrations of gases

or vapors. This exclusion generally applies to process or

product analyzing systems equipment.

All specifications are subject to change without notice.

Table of Contents

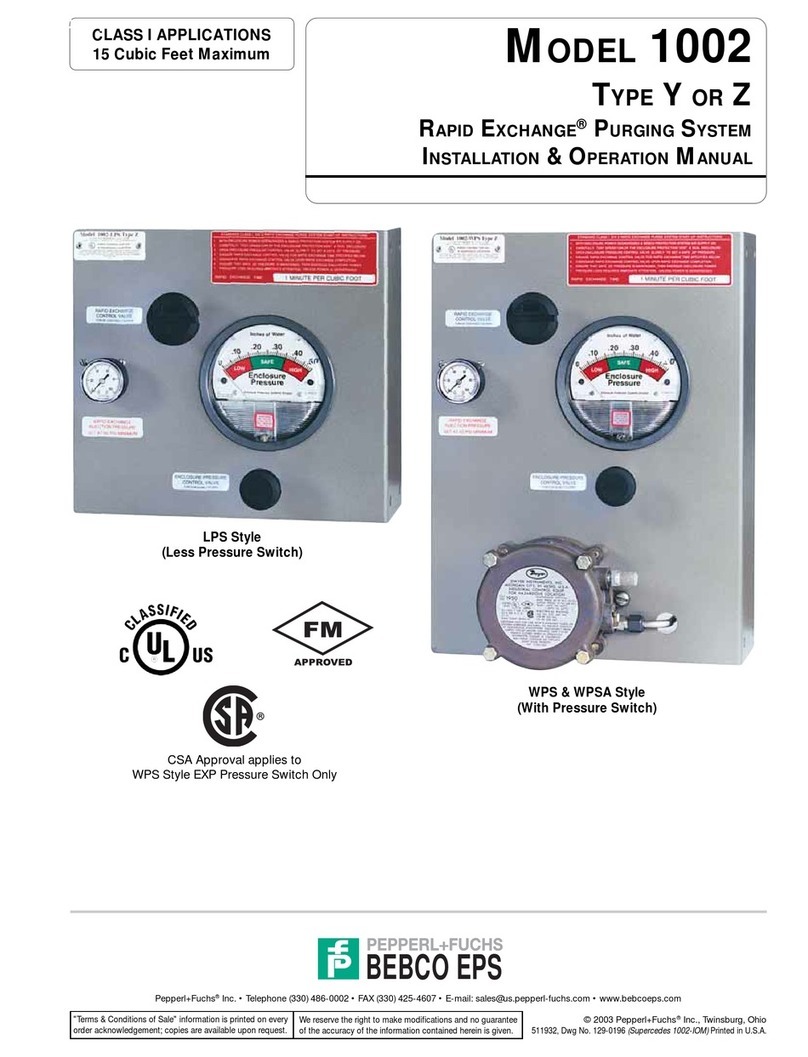

Page 2 System Purpose and Description

Purpose, System Description, Important

Notes

Page 3 Identifying Your System

Defines specific features of the system

Page 4 General Information

System & Material Specifications, System Acces-

sories, Spare Parts, Tools & Test Equipment

Page 5 Enclosure and Device Design

Design Requirements, Adjacent Enclosures,

Device Ventilation, Temperature Limitations

Page 6 Installation Overview

Installation Diagram

Page 7 Getting Started

Establishing Connection Sizes, Determining

Enclosure Inlet & Outlet Connection Locations

Page 8 System Mounting

LH, RH, TM, BM & WM Configurations,

FM & PM Configurations

Page 9 Special Mounting Information

ECK, ILFK Connection Diagram, Typical Panel

Mount Diagram

Page 10 Mounting Plate Dimensions

Mounting Plate Dimension Diagrams

Page 11 Mounting Plate Dimensions (cont.)

Mounting Plate Dimension Diagrams

Page 12 Hardware Mounting

Optional Enclosure Protection Vent, Warning

Nameplates

Purpose

Pepperl+Fuchs' Bebco EPS System allows the use of general-

purpose or nonrated electrical or electronic devices, with

exception to devices which produce excessive heat, utilize

combustible gas, or expose arcing contacts to the hazardous

atmosphere, in NEMA (National Electrical Manufacturers

Association) 4 or 12 enclosures in the place of explosion

proof NEMA 7 enclosures. Other purposes include heat,

moisture and dust contamination prevention.

Description

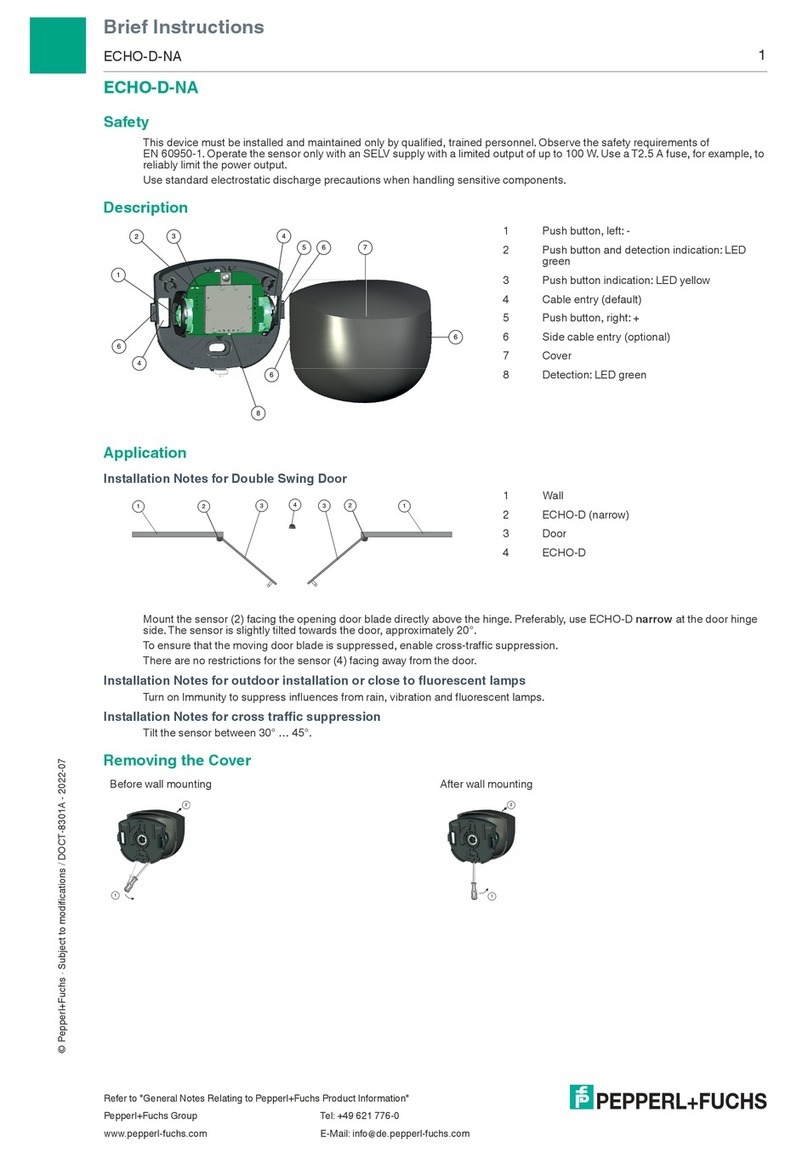

Model 1001A is an enclosure pressurization or purging

system that operates on a supply of compressed instrument

air or inert gas. It regulates and monitors pressure within

sealed (protected) enclosures, to prevent combustible

dust accumulation or remove and prevent flammable gas

or vapor accumulations. In Class II areas, the system

maintains a “safe” (1.0") pressure. In Class I areas, the

system accomplishes four air exchanges and maintains

a “safe” (0.25") pressure. These processes reduce the

hazardous (classified) area rating within the enclosure(s), in

accordance with the NEC - NFPA 70, Article 500, NFPA 496

and ISA 12.4

http://www.RSPSupply.com/p-6798-Hoffman-A1001YZUMC2-Purging-Pressurization-System-10-CF.aspx