Subject to modifications without notice

Pepperl+Fuchs Group

www.pepperl-fuchs.com

USA: +1 330 486 0002

Singapore: +65 6779 9091

Copyright Pepperl+Fuchs

Germany: +49 621 776 2222

DOCT-1723 02/2009

1

Operatin

Instructions

Place Holder Barrier – K-System

Versions

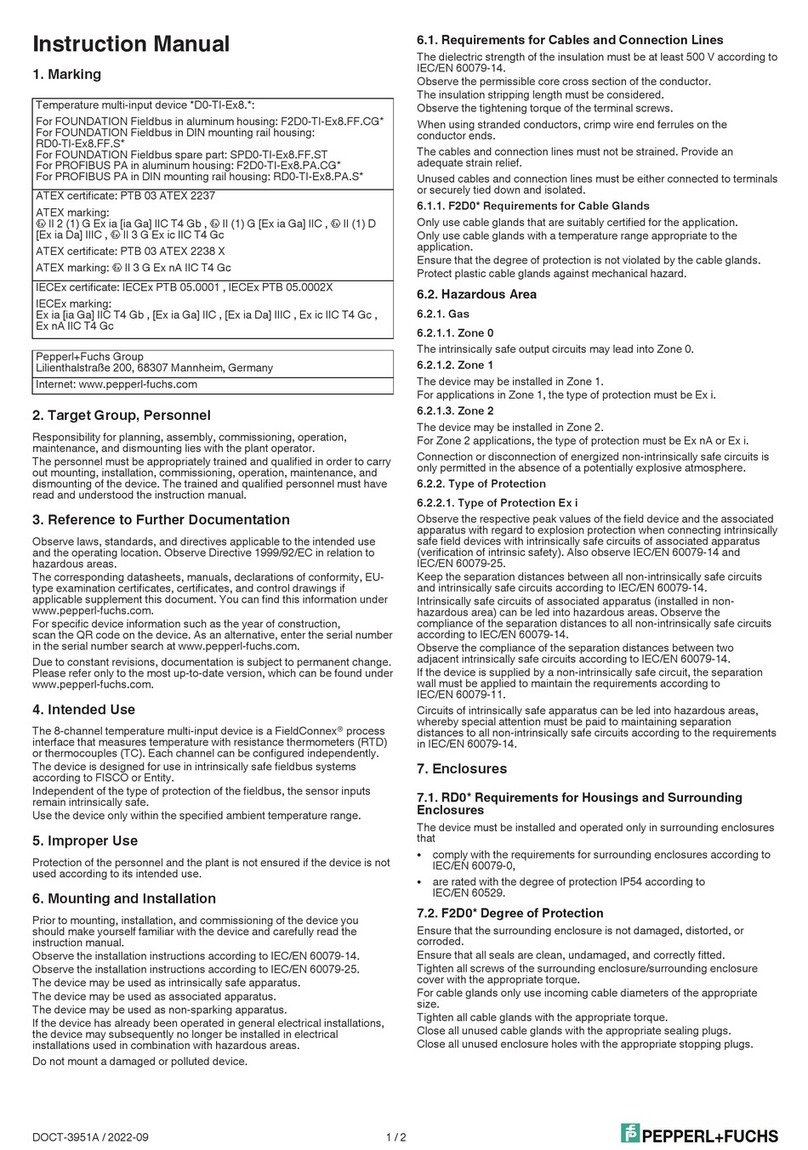

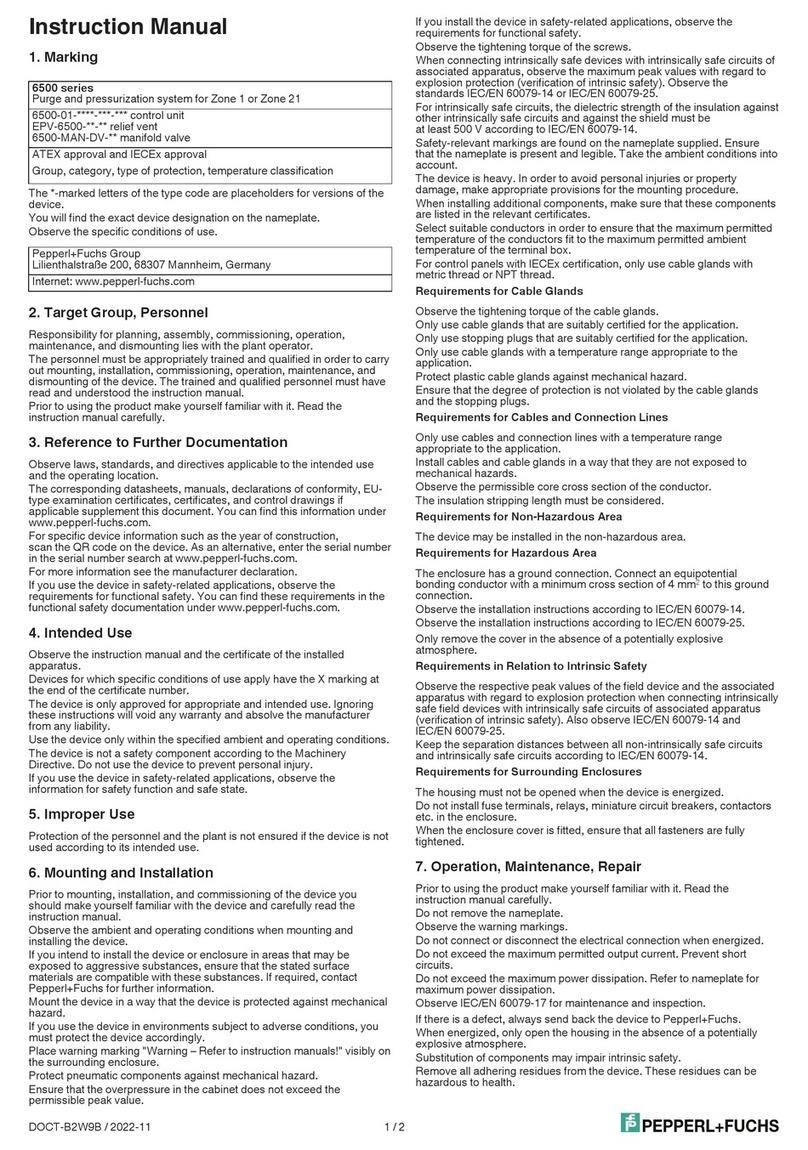

Safety information

The corresponding data sheets and the declaration of

conformity are an integral part of this document.

Intended use

Laws and regulations applicable to the usage or planned

purpose of usage must be observed. Devices are only

approved for proper usage in accordance with intended use.

Improper handling will result in voiding of any warrantee or

manufacturer's responsibility.

The devices are not suitable for the isolation of signals in

power engineering.

Protection of operating personnel and the system is not

ensured if the product is not used in accordance with its

intended use.

Installation and commissioning

Commissioning and installation must be carried out by

specially trained and qualified personnel only.

Installation of the interface devices in the

safe area

The devices are constructed to satisfy the IP20 protection

classification and must be protected from adverse

environmental conditions such as water spray or dirt

exceeding the pollution degree 2.

The devices must be installed outside the hazardous area!

The installation of the intrinsically safe circuits is to be

conducted in accordance with the relevant installation

regulations. It is especially important to ensure that all non-

intrinsically safe circuits are safely isolated (see section

"Internal connections").

The respective peak values of the field device and the

associated device with regard to explosion protection should

be considered when connecting intrinsically safe field devices

with the intrinsically safe circuits of devices (demonstration of

intrinsic safety). EN 60079-14/IEC 60079-14 is to be observed

(where appropriate). The K*D0-LGH* is passive, the

intrinsically safe data corresponds to that in the connected

devices.

When connecting several intrinsically safe current circuits,

these current circuits are to be considered as connected.

Installation and commissioning of the

interface devices within Zone 2/Div. 2 of the

hazardous area

Only devices with the corresponding manufacturer's

declaration of conformity or separate certificate of conformity

can be installed in Zone 2/Div. 2.

The individual data sheets indicate whether these conditions

are met.

The devices should be installed in a switch or junction box that:

• meets at least IP54 in accordance to EN 60529.

• meets to the requirements of resistance to light and

resistance to impact according to EN 60079-0/

IEC 60079-0.

• meets to the requirements of thermal endurance according

to EN 60079-15/IEC 60079-15.

• must not cause ignition danger by electrostatic charge

during intended use, maintenance and cleaning.

The installation of the intrinsically safe circuits is to be

conducted in accordance with the relevant installation

regulations. It is especially important to ensure that all non-

intrinsically safe circuits are safely isolated (see section

"Internal connections").

The respective peak values of the field device and the

associated device with regard to explosion protection should

be considered when connecting intrinsically safe field devices

with the intrinsically safe circuits of devices (demonstration of

intrinsic safety). EN 60079-14/IEC 60079-14 is to be observed

(where appropriate). The K*D0-LGH* is passive, the

intrinsically safe data corresponds to that in the connected

devices.

When connecting several intrinsically safe current circuits,

these current circuits are to be considered as connected.

The manufacturer's declaration of conformity should be

observed. It is especially important to observe the "special

conditions" if these are included in the certificates.

Repair and maintenance

Maintenance is not required.

Fault elimination

Only those changes that are listed in the section "Internal

connections" may be performed on devices that are operated

in connection with hazardous areas. Repairs to a device may

also only be performed at these locations.

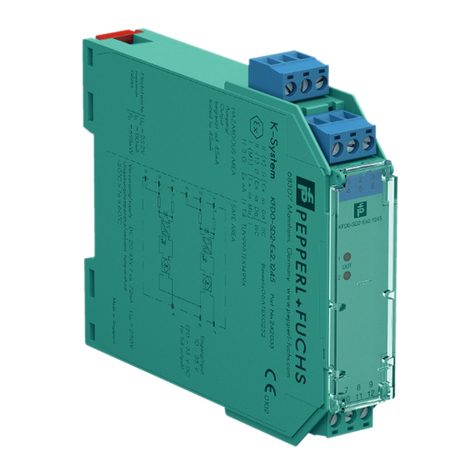

KCD0-LGH empty housing, internal connection via

jumpers possible, for intrinsically safe

and non-intrinsically safe circuits

KFD0-LGH empty housing, internal connection via

jumpers possible, for intrinsically safe

and non-intrinsically safe circuits

KFD0-LGH-5T empty housing, internal connection via

jumpers possible, for intrinsically safe

and non-intrinsically safe circuits,

5terminals

KFD0-LGH-Y34868 empty housing, no internal connection

possible

KFD0-LGH-Y39343 empty housing, internal connection via

DIP switches possible, for intrinsically

safe and non-intrinsically safe circuits

KFD0-LGH-GN empty housing, internal connection via

jumpers possible, only for intrinsically

safe circuits