Instruction Manual

1. Marking

Temperature multi-input device *D0-TI-Ex8.*:

For FOUNDATION Fieldbus in aluminum housing: F2D0‑TI‑Ex8.FF.CG*

For FOUNDATION Fieldbus in DIN mounting rail housing:

RD0‑TI‑Ex8.FF.S*

For FOUNDATION Fieldbus spare part: SPD0‑TI‑Ex8.FF.ST

For PROFIBUS PA in aluminum housing: F2D0‑TI‑Ex8.PA.CG*

For PROFIBUS PA in DIN mounting rail housing: RD0‑TI-Ex8.PA.S*

ATEX certificate: PTB 03 ATEX 2237

ATEX marking:

1 II 2 (1) G Ex ia [ia Ga] IIC T4 Gb , 1 II (1) G [Ex ia Ga] IIC , 1 II (1) D

[Ex ia Da] IIIC , 1 II 3 G Ex ic IIC T4 Gc

ATEX certificate: PTB 03 ATEX 2238 X

ATEX marking: 1 II 3 G Ex nA IIC T4 Gc

IECEx certificate: IECEx PTB 05.0001 , IECEx PTB 05.0002X

IECEx marking:

Ex ia [ia Ga] IIC T4 Gb , [Ex ia Ga] IIC , [Ex ia Da] IIIC , Ex ic IIC T4 Gc ,

Ex nA IIC T4 Gc

Pepperl+Fuchs Group

Lilienthalstraße 200, 68307 Mannheim, Germany

Internet: www.pepperl-fuchs.com

2. Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation,

maintenance, and dismounting lies with the plant operator.

The personnel must be appropriately trained and qualified in order to carry

out mounting, installation, commissioning, operation, maintenance, and

dismounting of the device. The trained and qualified personnel must have

read and understood the instruction manual.

3. Reference to Further Documentation

Observe laws, standards, and directives applicable to the intended use

and the operating location. Observe Directive 1999/92/EC in relation to

hazardous areas.

The corresponding datasheets, manuals, declarations of conformity, EU-

type examination certificates, certificates, and control drawings if

applicable supplement this document. You can find this information under

www.pepperl-fuchs.com.

For specific device information such as the year of construction,

scan the QR code on the device. As an alternative, enter the serial number

in the serial number search at www.pepperl-fuchs.com.

Due to constant revisions, documentation is subject to permanent change.

Please refer only to the most up-to-date version, which can be found under

www.pepperl-fuchs.com.

4. Intended Use

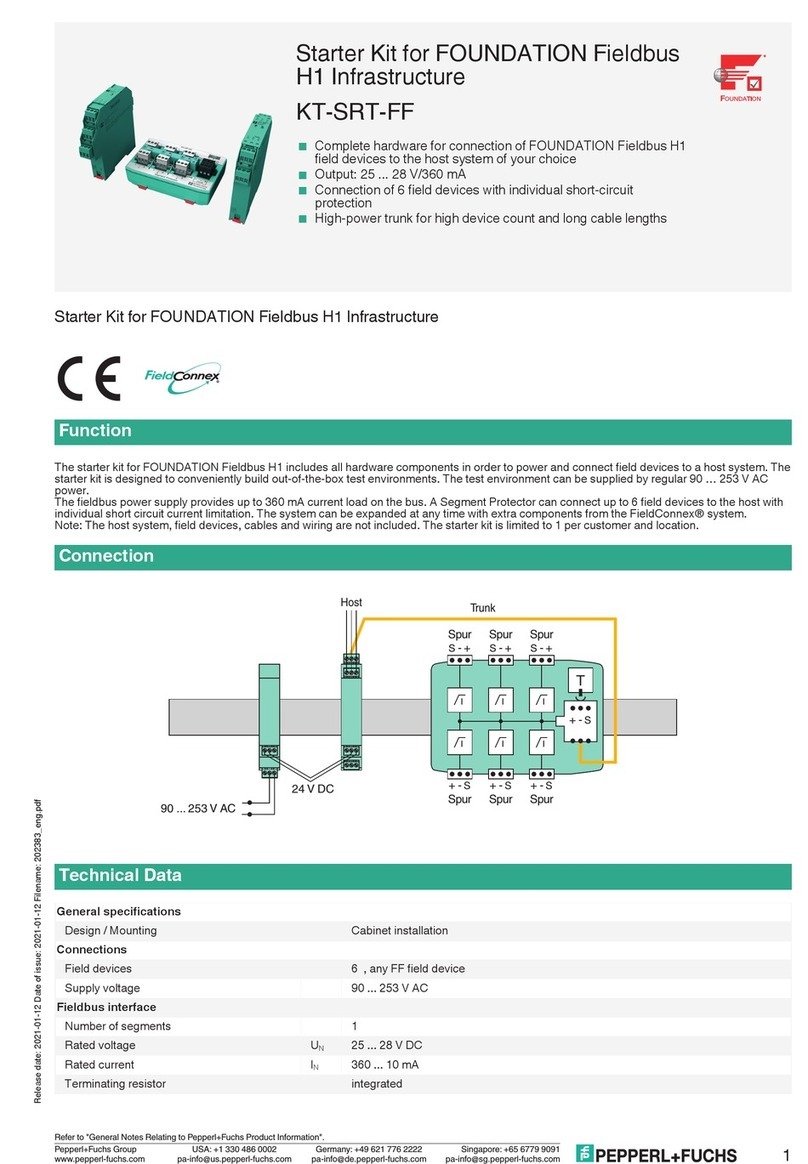

The 8-channel temperature multi-input device is a FieldConnex® process

interface that measures temperature with resistance thermometers (RTD)

or thermocouples (TC). Each channel can be configured independently.

The device is designed for use in intrinsically safe fieldbus systems

according to FISCO or Entity.

Independent of the type of protection of the fieldbus, the sensor inputs

remain intrinsically safe.

Use the device only within the specified ambient temperature range.

5. Improper Use

Protection of the personnel and the plant is not ensured if the device is not

used according to its intended use.

6. Mounting and Installation

Prior to mounting, installation, and commissioning of the device you

should make yourself familiar with the device and carefully read the

instruction manual.

Observe the installation instructions according to IEC/EN 60079-14.

Observe the installation instructions according to IEC/EN 60079-25.

The device may be used as intrinsically safe apparatus.

The device may be used as associated apparatus.

The device may be used as non-sparking apparatus.

If the device has already been operated in general electrical installations,

the device may subsequently no longer be installed in electrical

installations used in combination with hazardous areas.

Do not mount a damaged or polluted device.

6.1. Requirements for Cables and Connection Lines

The dielectric strength of the insulation must be at least 500 V according to

IEC/EN 60079-14.

Observe the permissible core cross section of the conductor.

The insulation stripping length must be considered.

Observe the tightening torque of the terminal screws.

When using stranded conductors, crimp wire end ferrules on the

conductor ends.

The cables and connection lines must not be strained. Provide an

adequate strain relief.

Unused cables and connection lines must be either connected to terminals

or securely tied down and isolated.

6.1.1. F2D0* Requirements for Cable Glands

Only use cable glands that are suitably certified for the application.

Only use cable glands with a temperature range appropriate to the

application.

Ensure that the degree of protection is not violated by the cable glands.

Protect plastic cable glands against mechanical hazard.

6.2. Hazardous Area

6.2.1. Gas

6.2.1.1. Zone 0

The intrinsically safe output circuits may lead into Zone 0.

6.2.1.2. Zone 1

The device may be installed in Zone 1.

For applications in Zone 1, the type of protection must be Ex i.

6.2.1.3. Zone 2

The device may be installed in Zone 2.

For Zone 2 applications, the type of protection must be Ex nA or Ex i.

Connection or disconnection of energized non-intrinsically safe circuits is

only permitted in the absence of a potentially explosive atmosphere.

6.2.2. Type of Protection

6.2.2.1. Type of Protection Ex i

Observe the respective peak values of the field device and the associated

apparatus with regard to explosion protection when connecting intrinsically

safe field devices with intrinsically safe circuits of associated apparatus

(verification of intrinsic safety). Also observe IEC/EN 60079-14 and

IEC/EN 60079-25.

Keep the separation distances between all non-intrinsically safe circuits

and intrinsically safe circuits according to IEC/EN 60079-14.

Intrinsically safe circuits of associated apparatus (installed in non-

hazardous area) can be led into hazardous areas. Observe the

compliance of the separation distances to all non-intrinsically safe circuits

according to IEC/EN 60079-14.

Observe the compliance of the separation distances between two

adjacent intrinsically safe circuits according to IEC/EN 60079-14.

If the device is supplied by a non-intrinsically safe circuit, the separation

wall must be applied to maintain the requirements according to

IEC/EN 60079-11.

Circuits of intrinsically safe apparatus can be led into hazardous areas,

whereby special attention must be paid to maintaining separation

distances to all non-intrinsically safe circuits according to the requirements

in IEC/EN 60079-14.

7. Enclosures

7.1. RD0* Requirements for Housings and Surrounding

Enclosures

The device must be installed and operated only in surrounding enclosures

that

lcomply with the requirements for surrounding enclosures according to

IEC/EN 60079-0,

lare rated with the degree of protection IP54 according to

IEC/EN 60529.

7.2. F2D0* Degree of Protection

Ensure that the surrounding enclosure is not damaged, distorted, or

corroded.

Ensure that all seals are clean, undamaged, and correctly fitted.

Tighten all screws of the surrounding enclosure/surrounding enclosure

cover with the appropriate torque.

For cable glands only use incoming cable diameters of the appropriate

size.

Tighten all cable glands with the appropriate torque.

Close all unused cable glands with the appropriate sealing plugs.

Close all unused enclosure holes with the appropriate stopping plugs.

DOCT-3951A / 2022-09 1 / 2