2

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

MLV11 Series - Introduction

- Operating mode:

(Only for sensors with light guide

connection MLV11-LL...)

Some of these settings are not avail-

able on through-beam sensors and

are only possible on the receiver:

Description

Setting the sensitivity

Through-beam sensorM11/MV11...

• Direct detection

• Through-beam mode

Hysteresis

Pulse frequency

Emitter disconnection

The emitter is equipped with a test input (switches emitter off).

-Manually(using the membrane keys)

- Automatically (TEACH-IN)

Note:

The sensitivity adjustment (teach in or manually) is maintained even after the oper-

ating voltage is turned off.

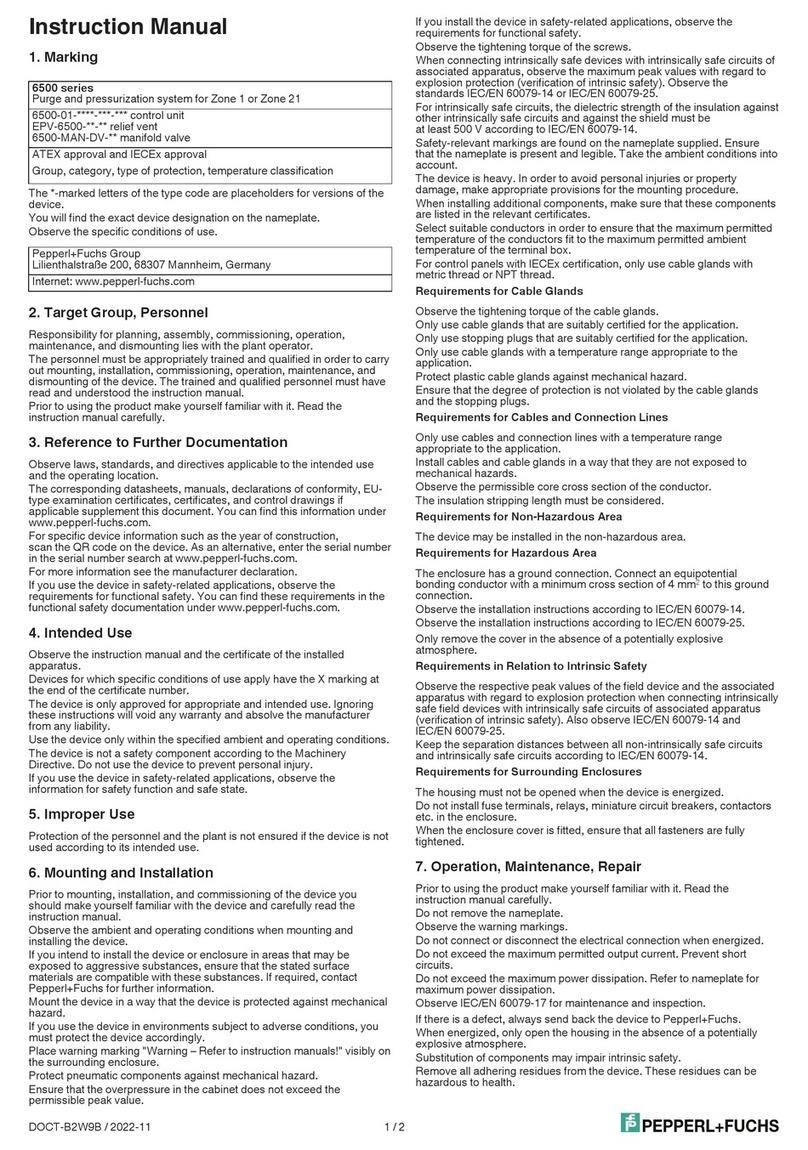

Sensitivity / adjustment using the membrane keys

On delivery, the sensitivity of the photoelectric sensor is set to maximum over the

whole operating distance of 0 m ... 15 m. It is possible via the membrane key to

achieve the detection of material with partial optical absorption (detection of partly

transparent or small objects) or to reduce the effective operating distance (improve-

ment of the interference light suppression).

A useful adjustment can be achieved in the 2 m ... 15 m range. In this range, the

automatic adjustment (TEACH-IN) ensures a function with optimum signal reserve.

Manual adjustment

1) Align the emitter and receiver correctly. The light path must be unobstructed.

2) If necessary, simultaneously push the "+" and "-" buttons for 5 seconds until

the green LED flashes once. The sensor is now unlocked.

The light path must be unobstructed!

3) Using the "+" and "-" buttons, the sensitivity of the sensor can be adjusted (the

red LED flashes with each keystroke, the yellow LED indicates the switching

status).

The push buttons feature a repeat function: simply hold down the key for re-

peated actuation. The sensitivity adjustment is maintained even after the op-

erating voltage is turned off.

Note:

If the red LED does not flash when the key is pushed, then the sensor is either

at the end of the adjustable range or the keypad is locked.

Manual Adjustment

EmitterReceiver

Automatic Adjustment (Dynamic Mode for Moving Targets)

1) Align the emitter and receiver correctly. The light path must be unobstructed.

2) If necessary, simultaneously push the "+" and "-" buttons for 5 seconds until

the green LED flashes once. Release the keys briefly. The sensor is now un-

locked.

The light path must be unobstructed!

3) Simultaneously push the "+" and "-" buttons (approx. 2 s) until the green LED

flashes, then release both keys. The sensor is now in the TEACH-IN mode as

indicated by the green LED flashing at 2 Hz.

4) The teaching process has finished when the green LED remains on.

Automatic Adjustment

EmitterReceiver