3

SAFETY !!SAFETY FIRST!!

This symbol precedes specic safety instructions throughout this manual. When read-

ing the manual, pay close attention to the information that follows this symbol.

FAILURE TO FOLLOW INSTRUCTIONS IN THIS MANUAL COULD RESULT IN PERSONAL

INJURY OR DEATH. READ ENTIRE MANUAL BEFORE OPERATING THE TEDDER.

Keep hands, feet and clothing away from the machine’s power take-o (PTO) shaft and any

other moving parts until the machine has been shut down and the power source has been

locked out.

Do not adjust, unclog, lubricate, or service the tedder until it has been shut down.

Support the tedder securely while working under it.

Be certain all bystanders and animals are a safe distance away before folding or unfolding

the tedder.

Never allow anyone to ride on the tractor or the tedder.

Before transporting, make sure hands-free transport lock is latched in place.

When transporting, never exceed a speed of 25 MPH and avoid sudden turns.

Be constantly aware of the ends of the machine to avoid collision with other objects.

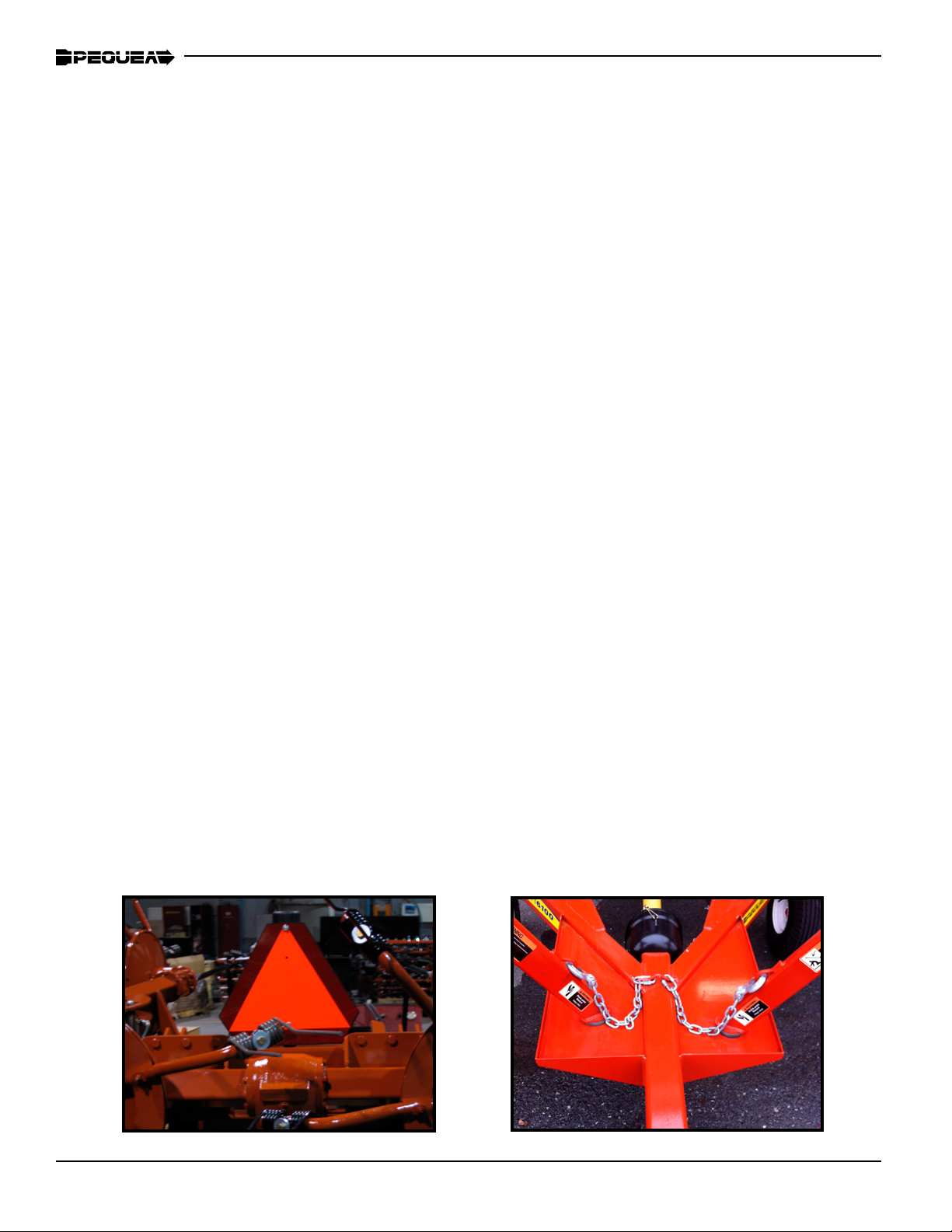

When transporting the machine on public roads use the proper reectors, lights, and slow

moving vehicle signs required by local government agencies. Pequea will not be liable for any

trac violations.

Be sure to check all fasteners before and after every use, this is especially important when

the tedder is new but is a good practice on any machinery with high vibration levels.

Be careful around hydraulic hoses and ttings. Never go near hydraulic leaks. High pressure

leaks can puncture skin and cause serious injury or death!

Do not attempt to fold the tedder until the machine is on at ground. Folding on uneven terrain

can cause the tedder to ip over.

Power Source Safety

Do not use a PTO shaft without a rotating shield in good working order. Make sure drive sys-

tem safety shields are in place on both the tractor and the tedder.

Do not overextend the PTO Shaft

PTO shield chains must be attached to the tractor and/or the tedder to keep the shield from

rotating.