TECHNICAL NOTICE TOP CROLL S - TOP CROLL L C0041800E (050722)

5

EN

These instructions explain how to correctly use your equipment. Only certain

techniques and uses are described.

The warning symbols inform you of some potential dangers related to the use of your

equipment, but it is impossible to describe them all. Check Petzl.com for updates

and additional information.

You are responsible for heeding each warning and using your equipment correctly.

Any misuse of this equipment will create additional dangers. Contact Petzl if you

have any doubts or difficulty understanding these instructions.

1. Field of application

Personal protective equipment (PPE) used for fall protection.

Chest harness for converting a seat harness into a fall arrest harness. The TOP

CROLL S and TOP CROLL L chest harnesses must not be used alone. Only the seat

harness + TOP or TOP CROLL L or TOP CROLL S combinations that are defined as

compatible (see compatibility section) are EN 361: 2002 certified.

This product must not be pushed beyond its limits, nor be used for any purpose

other than that for which it is designed.

Responsibility

WARNING

Activities involving the use of this equipment are inherently dangerous.

You are responsible for your own actions, decisions and safety.

Before using this equipment, you must:

- Read and understand all Instructions for Use.

- Get specific training in its proper use.

- Become acquainted with its capabilities and limitations.

- Understand and accept the risks involved.

Failure to heed any of these warnings may result in severe injury or death.

This product must only be used by competent and responsible persons, or those

placed under the direct and visual control of a competent and responsible person.

You are responsible for your actions, your decisions and your safety and you assume

the consequences of same. If you are not able, or not in a position to assume this

responsibility, or if you do not fully understand the Instructions for Use, do not use

this equipment.

2. Nomenclature

(1) Shoulder straps, (2) Rear DOUBLEBACK adjustment buckle, (3) Front

DOUBLEBACK PLUS adjustment buckle, (4) Metal sternal attachment point,

(5) Textile sternal attachment point, (6) Elastic keepers, (7) Velcro keeper for

ASAP’SORBER, (8) Rear connecting quick link, (9) EN 12841 integrated CROLL S or

CROLL L rope clamp, (10) Cam, (11) Safety catch.

Principal materials:

Straps: polyester.

Adjustment buckles: steel, stainless steel, aluminum alloy.

Rear connecting quick link: stainless steel.

CROLL S and CROLL L: aluminum alloy (frame), stainless steel (cam).

3. Inspection, points to verify

Your safety depends upon the integrity of your equipment.

Petzl recommends a detailed inspection by a competent person at least once every

12 months (depending on current regulations in your country, and your conditions

of usage). Warning: your intensity of use may cause you to inspect your PPE more

frequently. Follow the procedures described at Petzl.com. Record the results on

your PPE inspection form: type, model, manufacturer contact info, serial number or

individual number, dates: manufacture, purchase, first use, next periodic inspection;

problems, comments, inspector’s name and signature.

Before each use

Chest harness:

Check the webbing at the attachment points, at the adjustment buckles and at the

safety stitching.

Look for cuts, wear and damage due to use, to heat, to chemicals...

Verify that the DOUBLEBACK and DOUBLEBACK PLUS buckles function properly.

CROLL S and CROLL L:

On the product, verify the absence of any cracks, deformation, marks, wear,

corrosion...

Check the condition of the frame, the attachment holes, the cam and safety catch,

the springs and the cam axle.

Check the mobility of the cam and the effectiveness of its spring.

Verify that the cam’s teeth are not dirty.

Warning: do not use this rope clamp if it has missing or worn-out teeth.

Rear connecting quick link:

On the product, verify the absence of any cracks, deformation, marks, wear,

corrosion...

Check the condition of the rear connecting quick links (frame, screw). Immediately

retire a product showing any defect that could reduce its strength.

During use

Regularly verify that the adjustment buckles are securely fastened. It is important

to regularly monitor the condition of the product and its connections to the other

equipment in the system. Make sure that all items of equipment are correctly

positioned with respect to each other.

WARNING:

- of foreign objects that can impede the operation of the cam,

- of situations where the safety catch can snag and cause the cam to open.

4. Compatibility

Verify that this product is compatible with the other elements of the system in your

application (compatible = good functional interaction).

Equipment used with your chest harness must meet current standards in your

country (e.g. EN 813 harnesses).

Use only harnesses that are defined as compatible. See the compatibility table.

5. Harness setup

a. Installation on the seat harness rear connection points

1. TOP CROLL L

Follow the instructions in the diagrams. Thread the DOUBLEBACK buckle properly.

2. TOP CROLL S

Install the two connecting quick links in the rear connection loops on the harness and

securely tighten them with a wrench. The two quick links must be able to move freely

and without interference. Any constraint or external pressure reduces their strength.

b. Installing the TOP CROLL S or TOP CROLL L on the harness ventral

connection point

The chest harness comes with an integrated CROLL that connects to the harness

with a RING OPEN, a DELTA quick link, an EN 362 locking carabiner designed for

triaxial loading (e.g. OMNI) or directly to the gated ventral attachment point.

RING OPEN: see specific Instructions for Use.

DELTA quick link: see specific Instructions for Use.

Attach the CROLL to the front of the seat harness by attaching the quick link to the

textile ventral chest harness-seat harness attachment point. Securely tighten with

a wrench.

Be sure to clip the plastic separator bar.

Do not use this directional quick link to attach a lanyard or energy absorber.

OMNI: see specific Instructions for Use.

Gated ventral attachment point: attach the CROLL to the small D.

The two screws must be present and securely tightened.

Carefully follow the instructions for assembly and disassembly: see indicative arrows.

It is not necessary to completely remove the screw to free the pin.

If you lose a screw, contact Petzl after-sales service.

c. Full-body harness setup

- Be sure to correctly stow the excess webbing (folded flat) in the keepers.

Adjustment and suspension test

Your harness must be adjusted to fit snugly to reduce the risk of injury in the event

of a fall.

You must move around and hang in the harness from each attachment point, with

your equipment, to verify that the harness fits properly, provides adequate comfort

for the intended use and that it is optimally adjusted.

6. EN 361: 2002 sternal fall arrest attachment

point

Only the sternal attachment point may be used to attach a fall arrest system, for

example a mobile fall arrester, an energy absorber..., or other system described in the

EN 363 standard. For ease of identification, this point is marked with the letter ‘A’.

Clearance: amount of free space below the user

The free space below the user must be sufficient to prevent the user from hitting

an obstacle in the event of a fall. Specific details on calculating clearance are found

in the Instructions for Use of the other components (energy absorbers, mobile fall

arrester...).

7. Ventral rope clamp: CROLL S or CROLL L

The CROLL is a type B rope adjustment device designed for ascending on the

work rope.

The CROLL must be used with a type A backup device on the safety rope

(e.g. with an ASAP mobile fall arrester for rope).

- The CROLL is not suitable for use in a fall arrest system.

- To meet the requirements of the EN 12841: 2006 type B standard, use EN 1891

type A low stretch kernmantle ropes: 10-11 mm diameter with CROLL S and 10-13

mm with CROLL L.

(Note: certification testing was performed using Petzl CLUB 10 mm, Petzl AXIS 11

mm and Teufelberger KM3 13 mm ropes.)

- Use a connecting assembly of maximum length 1 meter (lanyard + connectors +

devices).

- Do not allow slack in the rope between the rope adjustment device and the anchor,

in order to reduce the risk of a fall.

When your body weight is on the work rope, make sure that the safety rope is not

loaded.

A dynamic overload can damage the safety rope.

Function principle and test

This rope clamp is a device for ascending rope. It slides along the rope in one

direction and locks in the other direction.

The cam’s teeth initiate a clamping action that locks the rope by pinching it between

the cam and the frame. The slot in the cam allows mud to clear.

Installing and removing the rope

Pull the safety catch down and lock it on the frame of the device. The cam is thus

held open.

Put the rope in the device. Observe the Up/Down indicator. Release the safety catch

so that the cam presses against the rope. In this position the safety catch helps

prevent involuntary opening of the cam.

Removing the rope

Move the device up the rope while opening the safety catch to disengage the cam.

Rope ascent

Use the CROLL with another rope clamp (e.g. BASIC) and a foot loop. Always attach

yourself to the second rope clamp with an appropriate lanyard.

Angled traverse situation

Starting on an angled rope: put a leg over the rope to align it with the CROLL’s rope

channel.

Short descent

Slide the device slightly up the rope and simultaneously push the cam with your

index finger. Warning: do not manipulate the safety catch because there is a risk of

accidentally opening the cam.

Warning: for workers weighing over 100 kg, see the information on Solutions for

workers over 100 kg at Petzl.com.

8. Velcro keeper

The Velcro keeper may be used to hold your mobile fall arrester’s energy absorber

in a high position.

9. Accessories

A. To be used only as a connector holder for unused lanyard ends.

B. In the event of a fall, the connector holder releases the lanyard-end connector so

as to avoid impeding deployment of the energy absorber.

Warning: this attachment point is not a fall arrest attachment point.

10. Additional information

This product meets the requirements of Regulation (EU) 2016/425 on personal

protective equipment. The EU declaration of conformity is available at Petzl.com.

- You must have a rescue plan and the means to rapidly implement it in case of

difficulties encountered while using this equipment.

- The anchor point for the system should preferably be located above the user’s

position and should meet the requirements of the EN 795 standard (12 kN minimum

strength).

- In a fall arrest system, it is essential to check the required clearance below the user

before each use, in order to avoid hitting the ground or an obstacle in the event of

a fall.

- Make sure that the anchor point is correctly positioned, in order to limit the risk and

the length of a fall.

- A fall arrest harness is the only device allowable for supporting the body in a fall

arrest system.

- When using multiple items of equipment, a dangerous situation can arise in which

the safety function of an item of equipment can be affected by the safety function of

another item of equipment.

- WARNING: ensure that your products do not rub against abrasive or sharp

surfaces.

- Users must be medically fit for activities at height. WARNING: inert suspension in a

harness can result in serious injury or death.

- The Instructions for Use for each item of equipment used in conjunction with this

product must be followed.

- The Instructions for Use must be provided to the user of this equipment, in the

language of the country where the equipment is used.

- Make sure the markings on the product are legible.

The melting point of high-modulus polyethylene (140° C) is lower than that of nylon

and polyester.

When to retire your equipment:

WARNING: an exceptional event can lead you to retire a product after only one

use, depending on the type and intensity of usage and the environment of usage

(harsh environments, marine environments, sharp edges, extreme temperatures,

chemicals...).

A product must be retired when:

- It is over 10 years old and made of plastic or textiles.

- It has been subjected to a major fall or load.

- It fails to pass inspection. You have any doubt as to its reliability.

- You do not know its full usage history.

- When it becomes obsolete due to changes in legislation, standards, technique or

incompatibility with other equipment...

Destroy these products to prevent further use.

Icons:

A. Lifetime: 10 years - B. Marking - C. Acceptable temperatures - D. Usage

precautions - E. Cleaning/disinfection - F. Drying - G. Storage/transport - H.

Maintenance - I. Modifications/repairs (prohibited outside of Petzl facilities, except

replacement parts) - J. Questions/contact

3-year guarantee

Against any material or manufacturing defect. Exclusions: normal wear and tear,

oxidation, modifications or alterations, incorrect storage, poor maintenance,

negligence, uses for which this product is not designed.

Warning symbols

1. Situation presenting an imminent risk of serious injury or death. 2. Exposure to

a potential risk of accident or injury. 3. Important information on the functioning or

performance of your product. 4. Equipment incompatibility.

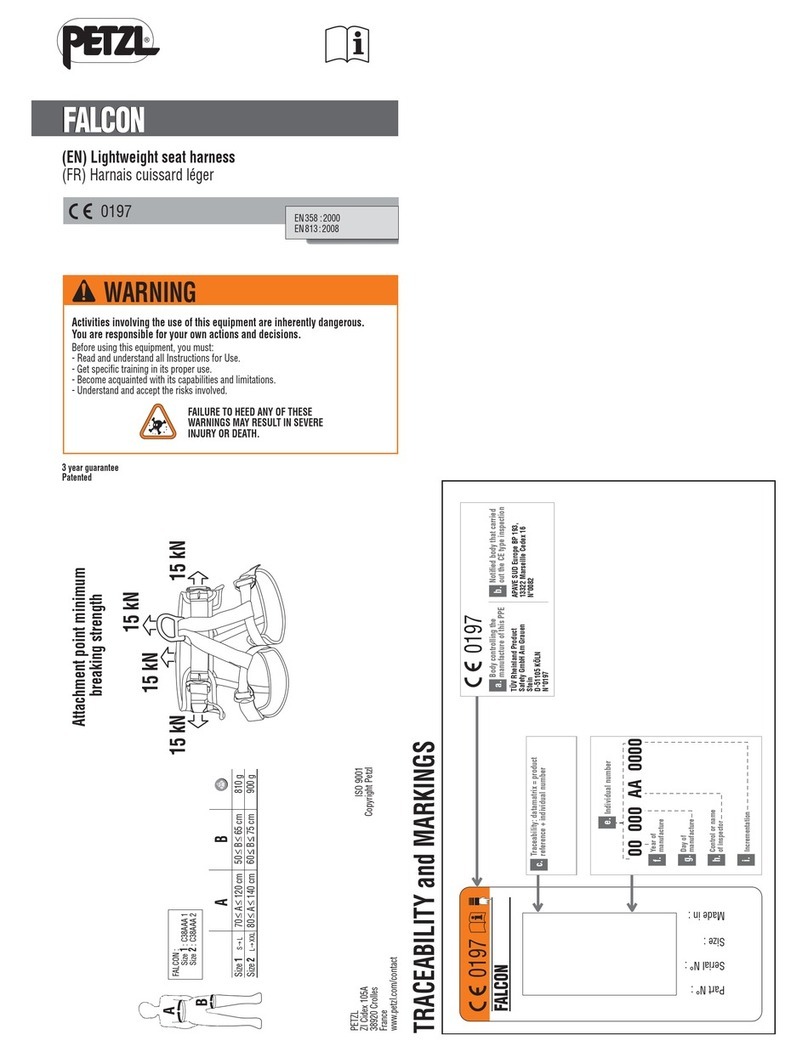

Traceability and markings

a. Meets PPE regulatory requirements. Notified body performing the EU type

examination - b. Number of the notified body responsible for the production control

of this PPE - c. Traceability: datamatrix - e. Serial number - f. Year of manufacture

- g. Month of manufacture - h. Batch number - i. Individual identifier - j. Standards

- k. Read the Instructions for Use carefully - l. Model identification - m. Date of

manufacture (month/year) - n. Nominal maximum load

This product is compliant with the Regulation

2016/425 on Personal Protective Equipment

as brought into UK law and amended.

Ce produit est conforme au règlement

2016/425 sur les équipements de protection

individuelle tel que transposé en droit

britannique et modifié.

Approved body performing the UKCA type

examination and the production control of

this PPE :

Organisme approuvé intervenant pour

l’examen UKCA de type et le contrôle de

production de cet EPI :

SGS United Kingdom Ltd

Inward Way

Rossmore Business Park

Ellesmere Port, Cheshire, CH65 3EN

United Kingdom

N° 0120

0120

Authorized Representative in UK : PETZL UK Agency, Unit 3-7, Tebay Business Park,

Old Tebay, Penrith, CA10 3SS, United Kingdom