Contents

System Description PITmode flex visu

1005364-EN-01 | 3

1 Introduction ............................................................................................................................ 5

1.1 Definition of symbols................................................................................................................. 5

2 Overview of systems for safety-related operating mode selection .................................. 6

3 Safety ...................................................................................................................................... 8

3.1 Intended use ............................................................................................................................. 8

3.2 Safety regulations ..................................................................................................................... 8

3.2.1 Additional documents that apply............................................................................................... 8

3.2.2 Use of qualified personnel ........................................................................................................ 8

3.2.3 Warranty and liability ................................................................................................................ 9

3.2.4 Disposal .................................................................................................................................... 9

3.3 Application conditions ............................................................................................................... 9

4 Security ................................................................................................................................... 12

4.1 Required security measures ..................................................................................................... 12

5 PITmode flex visu with PNOZmulti ...................................................................................... 13

5.1 Description................................................................................................................................ 13

5.1.1 System overview....................................................................................................................... 13

5.1.2 Safety features.......................................................................................................................... 14

5.1.3 Working areas........................................................................................................................... 15

5.1.4 Behaviour when the transponder key is removed..................................................................... 15

5.1.5 Acknowledge ............................................................................................................................ 16

5.1.6 Lock input ................................................................................................................................. 16

5.1.7 Service mode............................................................................................................................ 16

5.1.8 Audit trail................................................................................................................................... 16

5.2 System expansion .................................................................................................................... 16

5.3 Installation................................................................................................................................. 17

5.3.1 Connect PITreader ................................................................................................................... 17

5.3.2 Connect display unit ................................................................................................................. 17

5.4 Configuration ............................................................................................................................ 17

5.4.1 Configure PASvisu display unit................................................................................................. 17

5.4.2 Configure PITreader ................................................................................................................. 19

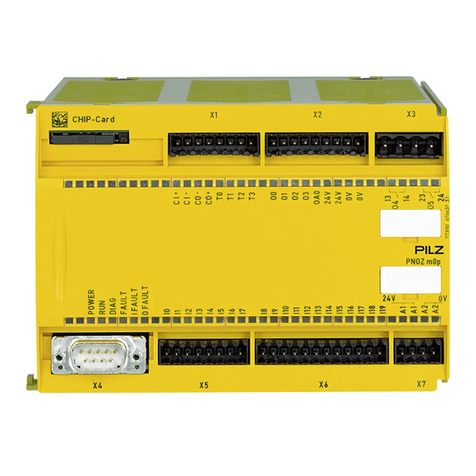

5.4.3 Configure PNOZmulti................................................................................................................ 19

5.4.3.1 Configure hardware .................................................................................................................. 19

5.4.3.2 Configure connection to the PITreader..................................................................................... 19

5.4.3.3 Configure connection to the Visu display unit........................................................................... 19

5.4.3.4 Configure MSO flex visu element ............................................................................................. 19

5.4.3.5 Configure safety function .......................................................................................................... 20

5.5 Operation .................................................................................................................................. 20

5.5.1 Select safe mode of operation MSO1 ... MSO8........................................................................ 20

5.5.2 Button status indicators ............................................................................................................ 22

5.5.3 Status and error messages through the PNOZmulti................................................................. 23

5.6 Examples for PITmode flex visu with PNOZ m B1 ................................................................... 26

5.6.1 Example 1................................................................................................................................. 26

5.6.2 Example 2................................................................................................................................. 26

5.6.3 Example 3................................................................................................................................. 27