Contents

Operating Manual PNOZ m C0

1006013-EN-02 | 3

1 Introduction ............................................................................................................................5

1.1 Validity of documentation ..........................................................................................................5

1.2 Using the documentation ..........................................................................................................5

1.3 Definition of symbols .................................................................................................................5

1.4 Third-party manufacturer licence information............................................................................6

2 Overview .................................................................................................................................7

2.1 Range........................................................................................................................................7

2.2 Unit features..............................................................................................................................7

2.3 Chip card...................................................................................................................................8

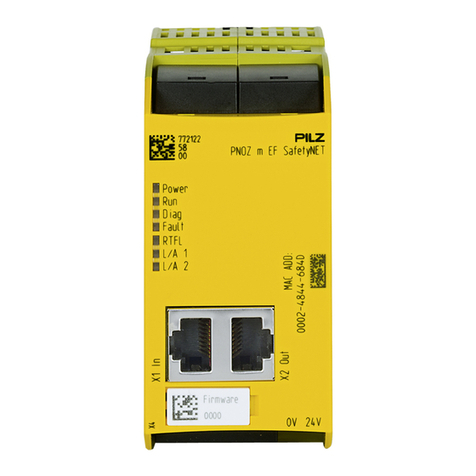

2.4 Front view..................................................................................................................................8

3 Safety ......................................................................................................................................10

3.1 Intended use .............................................................................................................................10

3.2 Applicable documentation .........................................................................................................11

3.3 System requirements ................................................................................................................11

3.4 Safety regulations .....................................................................................................................11

3.4.1 Safety assessment....................................................................................................................11

3.4.2 Use of qualified personnel.........................................................................................................11

3.4.3 Warranty and liability.................................................................................................................11

3.4.4 Disposal ....................................................................................................................................12

3.4.5 For your safety ..........................................................................................................................12

4 Security ...................................................................................................................................13

4.1 Implemented security measures ...............................................................................................13

4.2 Required security measures .....................................................................................................13

5 Function description ..............................................................................................................15

5.1 Integrated protection mechanisms............................................................................................15

5.2 Functions...................................................................................................................................15

5.3 Reaction times ..........................................................................................................................15

5.4 Block diagram ...........................................................................................................................16

5.5 Diagnostics................................................................................................................................16

5.6 Device security..........................................................................................................................16

5.6.1 User management.....................................................................................................................16

5.6.2 Security device key ...................................................................................................................17

6 Installation ..............................................................................................................................19

6.1 Control cabinet installation ........................................................................................................19

6.1.1 Mounting distances ...................................................................................................................20

6.2 Dimensions in mm.....................................................................................................................21

7 Commissioning ......................................................................................................................22

7.1 General wiring guidelines..........................................................................................................22

7.2 Connection ................................................................................................................................22

7.3 Load project from chip card.......................................................................................................24

7.4 Load project via USB port ........................................................................................................24

7.5 Function test during commissioning..........................................................................................24