Pioneer PL-560 User manual

Other Pioneer Turntable manuals

Pioneer

Pioneer PL-3000/HB User manual

Pioneer

Pioneer PL-50 User manual

Pioneer

Pioneer DC-Z93 User manual

Pioneer

Pioneer PL-55X User manual

Pioneer

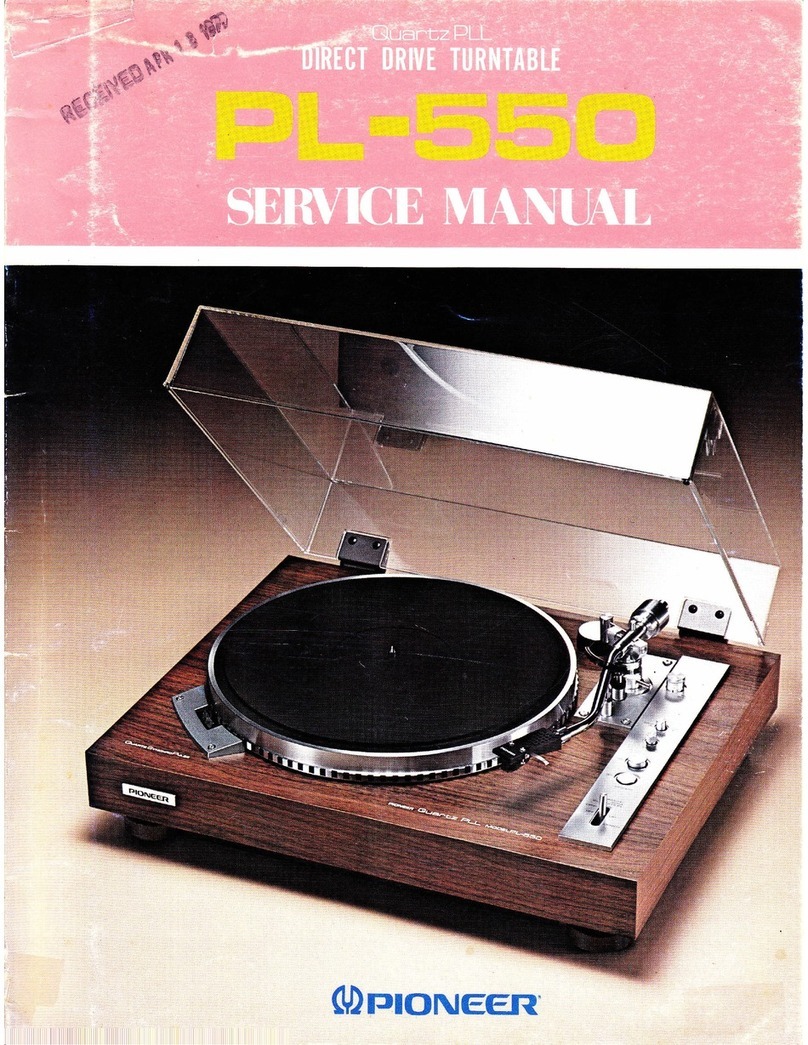

Pioneer PL-550 User manual

Pioneer

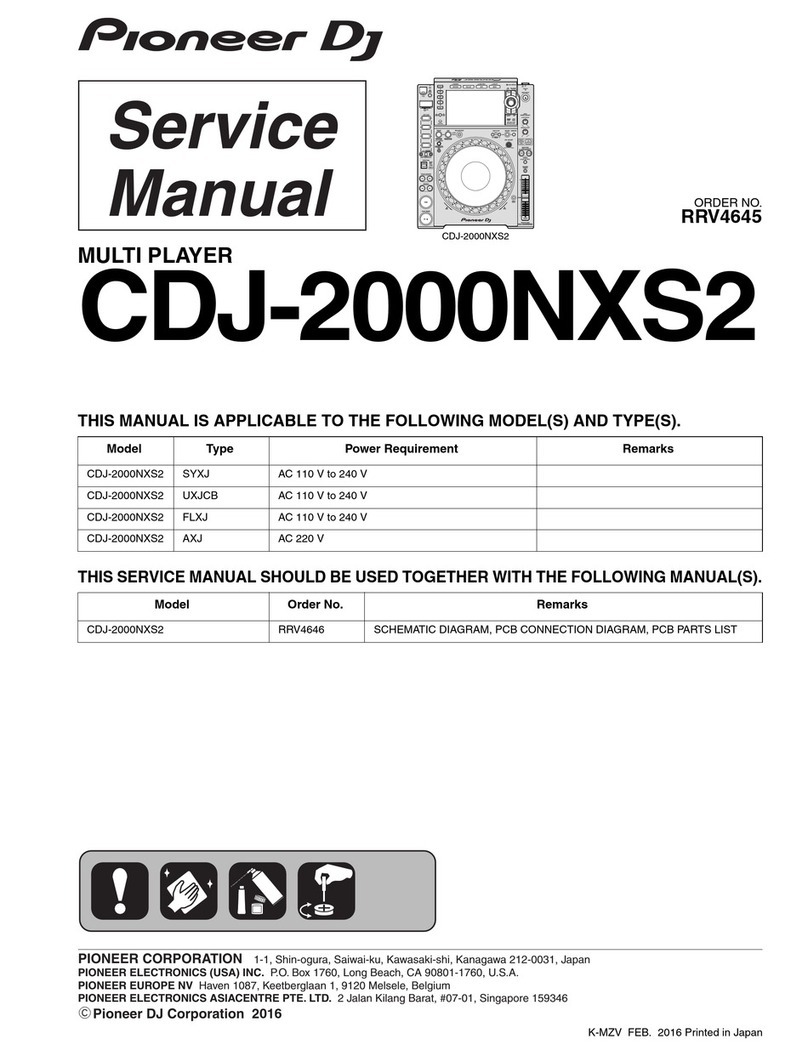

Pioneer CDJ-2000NXS2 User manual

Pioneer

Pioneer PL-600 User manual

Pioneer

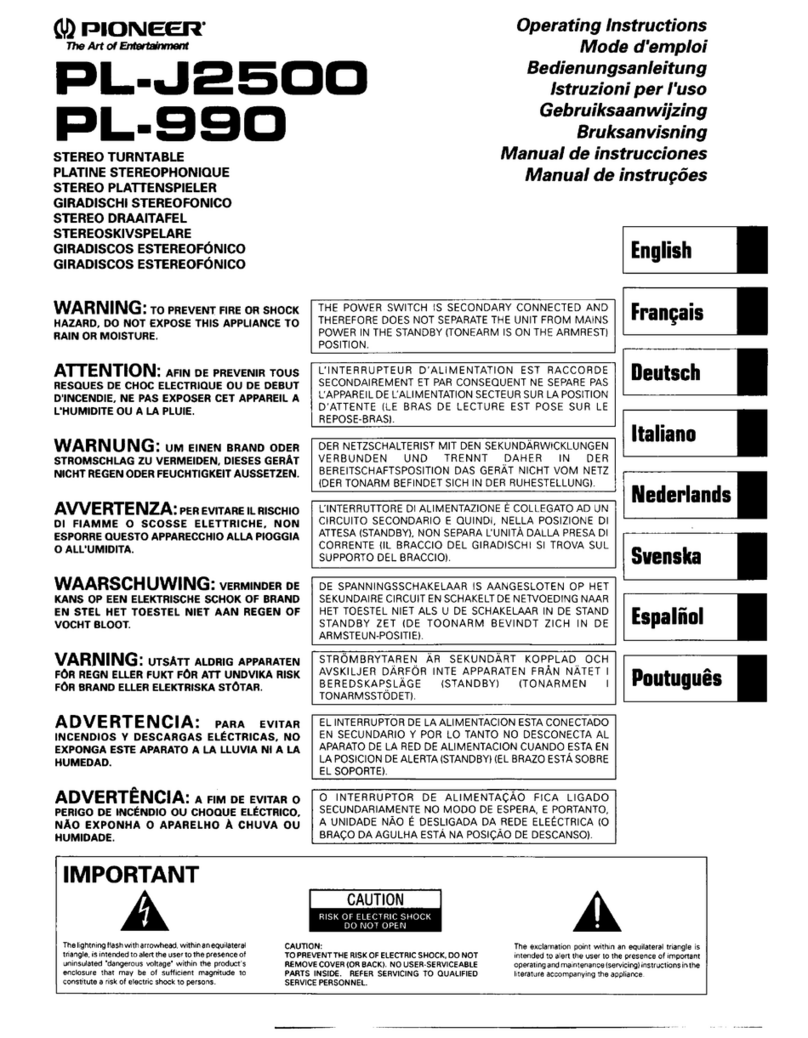

Pioneer PL-J2500 User manual

Pioneer

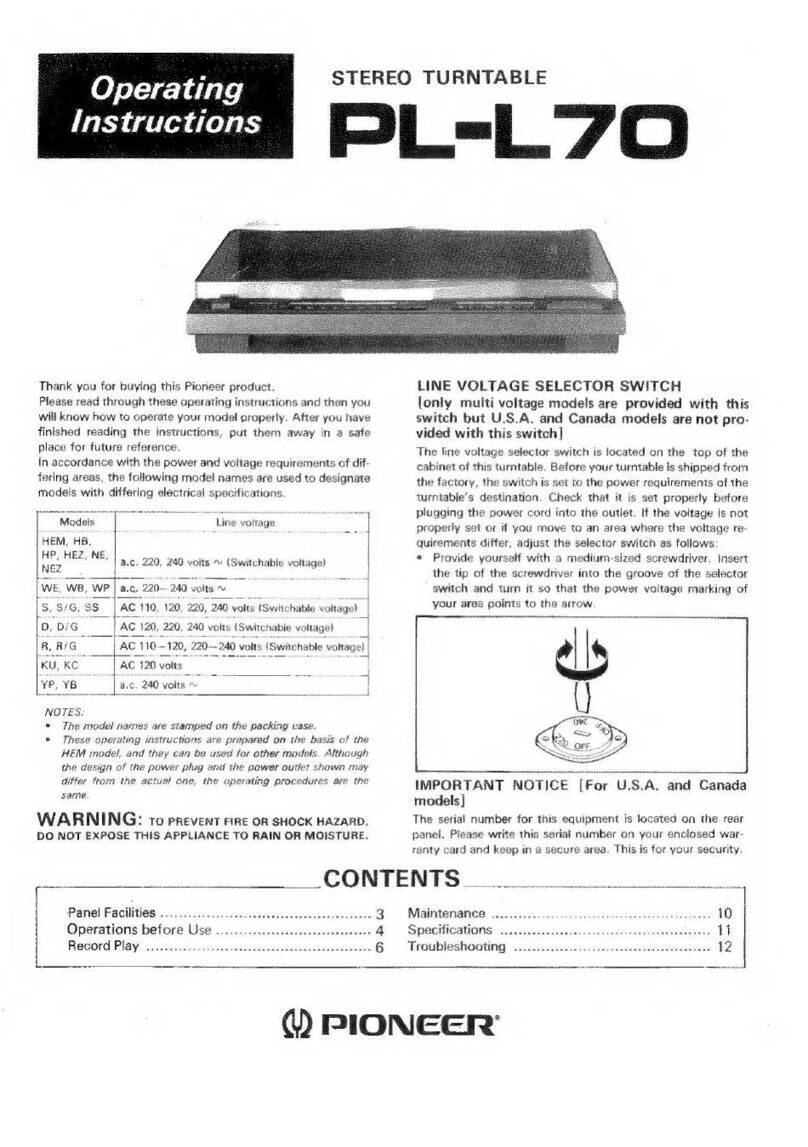

Pioneer PL-L70 User manual

Pioneer

Pioneer PL-L1000 User manual

Pioneer

Pioneer LD-V4300D User manual

Pioneer

Pioneer PL-15D-II User manual

Pioneer

Pioneer PL-707 User manual

Pioneer

Pioneer PL-516 KCT User manual

Pioneer

Pioneer PL-X420 User manual

Pioneer

Pioneer PL-550 User manual

Pioneer

Pioneer PL-430 WE User manual

Pioneer

Pioneer PL-V70 User manual

Pioneer

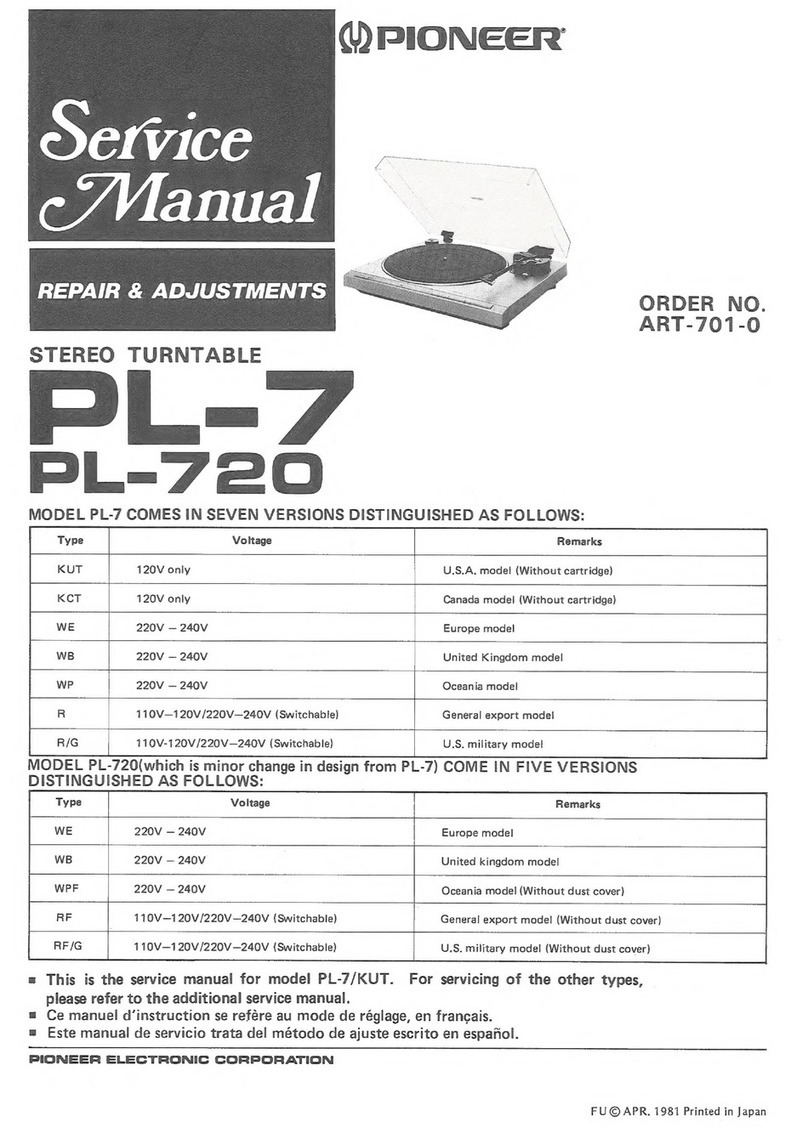

Pioneer PL-7 User manual

Pioneer

Pioneer PL-5 User manual