surface. Dust particles may enter the mechanism.

• Always switch off the machine first before removing

the plug from the wall socket.

Never use the spindle lock to stop the motor.

TROUBLESHOOTING

1. Machine fails to operate:

• Power turned off

• (Extension) cable damaged

2. The elektromotor hardly reaches maximum

speed:

• The extension cable is too thin and/or too long

• The mains voltage is lower than 230 V

3. Machine overheats:

• Air vents are blocked. Clean them with a dry cloth.

• The machine has been overloaded. Use the machine

for the purpose it is made for.

4. Excessive sparking or elektromotor runs

irregular.

• There’s dirt inside the motor or the carbon brushes

are worn. Replace the carbon brushes or bring the

machine to a specialized repair centre.

5. SERVICE & MAINTENANCE

MAINTENANCE

Make sure that the plug is removed from the mains when

carrying out maintenance work on the motor.

The Powercraft machines have been designed to

operate over a long period of time with a minimum of

maintenance. Continuous satisfactory operation

depends upon proper machine care and regular cleaning.

CLEANING

Regularly clean the machine housing with a soft cloth,

preferably after each use. Keep the ventilation slots free

from dust and dirt. If the dirt does not come off use a soft

cloth moistened with soapy water. Never use solvents

such as petrol, alcohol, ammonia water, etc. These

solvents may damage the plastic parts.

LUBRICATION

The machine requires no additional lubrication.

FAULTS

Should a fault occur, e.g. after wear of a part, please

contact the adress on the warranty card. In the back of

this manual you find an exploded view showing the parts

that can be ordered.

ENVIRONMENT

In order to prevent the machine from damage during

transport, it is delivered in a sturdy packaging. Most of

the packaging materials can be recycled. Take these

materials to the appropriate recycling locations.

Faulty and/or discarded electrical or electronic

apparatus have to be collected at the appropriate

recycling locations.

WARRANTY

The warranty conditions can be found on the separately

enclosed warranty card.

We declare under our sole responsibility that this

product is in conformity with the following standards or

standardized documents

EN 50144-1, EN50144-2-3,

EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3

in accordance with the regulations.

98/37/EEC

73/23/EEC

89/336/EEC

from 01-08-2004

Servotool

ZWOLLE NL

W. Kamphof

Quality Department

CE

ı

DECLARATION OF CONFORMITY (UK)

Powercraft 7

from the mains supply (use non metallic objects) and

avoid damaging internal parts.

• Though poor conditions of the electrical mains,

shortly voltage drops can appear when starting the

equipment. This can influence other equipment (eq.

blinking of a lamp). If the mains-impedance Zmax

<0.348 Ohm, such disturbances are not expected.

(In case of need, you may contact your local supply

authority for further information.

3. ASSEMBLY

Prior to mounting an accessory always unplug the

tool.

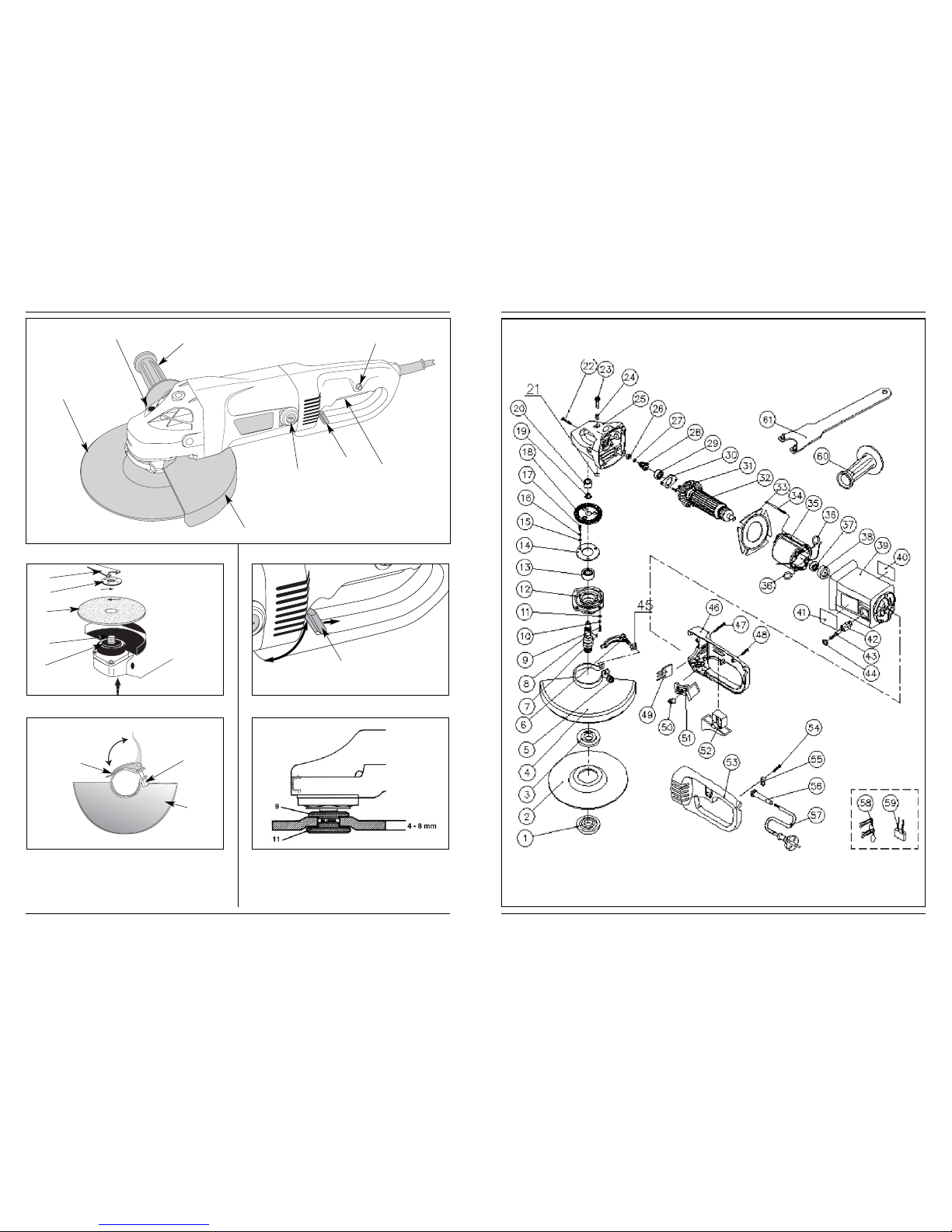

MOUNTING A GRINDING DISC.

Fig 2

Use grinding discs of the correct dimension. Use fibre

reinforced grinding discs only. The grinding disc must

not touch the edge of the guard.

• Press the spindle lock (3) and turn the spindle (10)

until it engages in the lock. Keep the spindle lock

pressed during this procedure.

• Remove the flange nut (11) from the spindle using the

spanner (12).

• Position the grinding disc (4) on the flange (9).

• Place the flange nut on the spindle an tighten it using

the spanner.

• Release the spindle lock and check that the spindle is

unlocked by rotating it.

MOUNTING THE PROTECTIVE GUARD

Fig. 2+3

Tool-les protective guard

The protective guard is pre-adjusted for the diameter of

the spindle shaft. If necessary, the tension of the clamping

lever can be adjusted by turning the adjustment-bolt

(13). Pay attention to the correct fitting of the guard (7)

on the spindle shaft (10).

• Open the clamping lever (14)

• Place the protective guard across the spindle shaft on

the machine head in the required position

• Close the clamping lever (14) to clamp the

protective guard (7).

Warning: the closed side of the protective guard has to

point towards the user.

ROTATING THE HANDGRIP

Fig. 4

The handgrip can be rotaded 90oregard to the machine

housing. This can result in a better control of the On/Off

switch during special working positions; for example for

grinding or left-hand users.

• Pull the knob (8) backwards with thumb and

forefinger.

• Rotate the handgrip in the new position (until the

blocking).

MOUNTING THE SIDE HANDLE

Fig 1

The side handle can be used for both left-hand and right-

hand control.

• Fasten the side handle (Fig. 5) for left-hand operation

on the right-hand side of the machine.

• Fasten the side handle for right-hand operation on

the left-hand side of the machine.

• Fasten the side handle for upright working at the top

of the machine.

Make sure that the side handle is fastened

properly and cannot loosen unexpectedly.

MOUNTING GRINDING DISCS AND

ROUGHING DISCS

Fig. 3 and 4 show how to mount the flange (11) when

using thick (4 – 8 mm) and thin (2,5 – 4 mm) discs.

4. USE

SPECIAL ATTENTION WHEN STARTING

THE MACHINE

• Clamp the workpiece and make sure that the

workpiece cannot slide from under the machine

during the cutting activities.

• When working with the machine, always hold it

firmly with both hands and provide for a secure

stance.

• Always direct the cable to the rear away from the

machine.

• Insert the mains plug only when the machine is

switched off.

• Apply the machine to the workpiece only when

switched on

Never use the machine for grinding magnesium

workpieces.

SWITCHING ON AND OFF

• This machine is equipped with a safety switch.

• Start the machine by pressing the “lock off” button

(to disengrage the switch) and switch on the

machine.

Before start working, the machine must be run

according to the max. speed.

OPERATION

• Hold the machine firmly and move it against the

workpiece. Move the grinding disc evenly across the

workpiece.

• Move the machine during roughing under an angle of

30º - 40º across the workpiece (fig. 7).

Never use grinding discs for roughing!

• The machine must always work opposite to the

direction of rotation. Therefore, never move the

machine in the other direction! Otherwise, the

danger exists of it being pushed uncontrolled out of

the cut (fig. 8).

• Inspect the grinding disc regularly. Worn discs have a

negative effect on efficiency of the machine. Replace

the grinding disc on time.

• Do not put the machine down when the motor is still

running. Do not place the machine on a dusty

6Powercraft